Preparation method of heat storage composite material based on nanoparticle electromagnetic wave absorption

A technology of nano-particles and composite materials, applied in the field of heat storage composite materials, can solve problems such as unsatisfactory heating speed and uniformity, inability to directly absorb solar energy, and sacrifice matrix heat storage materials to achieve low cost and uniform heating Good performance and high heat storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of gold nanoparticles

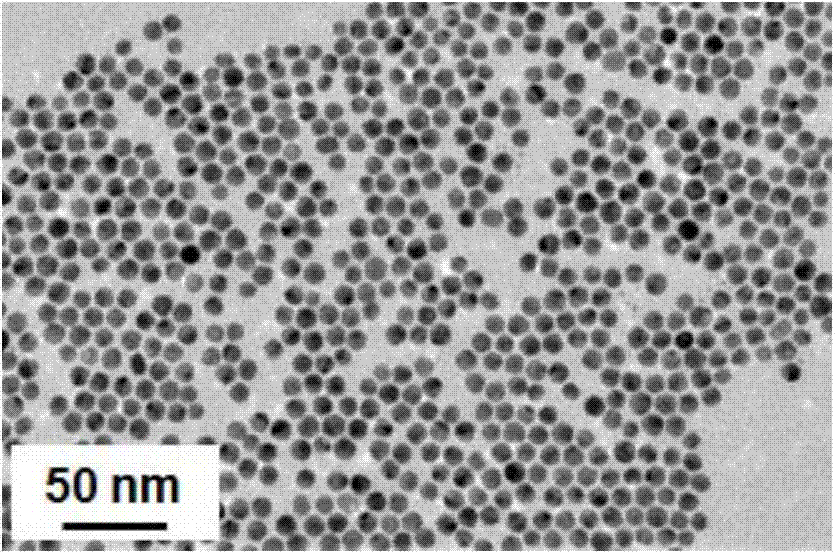

[0025] According to the recipe requirements, HAuCl 4 Dissolve in toluene by ultrasonic, add part of oleylamine, heat and stir, then pass through nitrogen atmosphere and cold water to reflux, after the reaction is complete, add methanol n-hexane mixed solution to the mixed solution and centrifuge at a high speed, remove the supernatant, and the obtained The nanoparticles are redispersed in toluene, the size of the nanoparticles is about 8±1nm, and the transmission electron microscope pictures are as follows: figure 1 shown.

[0026] (2) Preparation of nanocomposite heat storage materials

[0027] (3) Heat and melt the transparent paraffin heat storage material, add a certain amount of gold solution with stirring, and continue heating for a period of time to fully volatilize the toluene. After cooling, a nanocomposite heat storage material with evenly distributed gold nanoparticles is obtained.

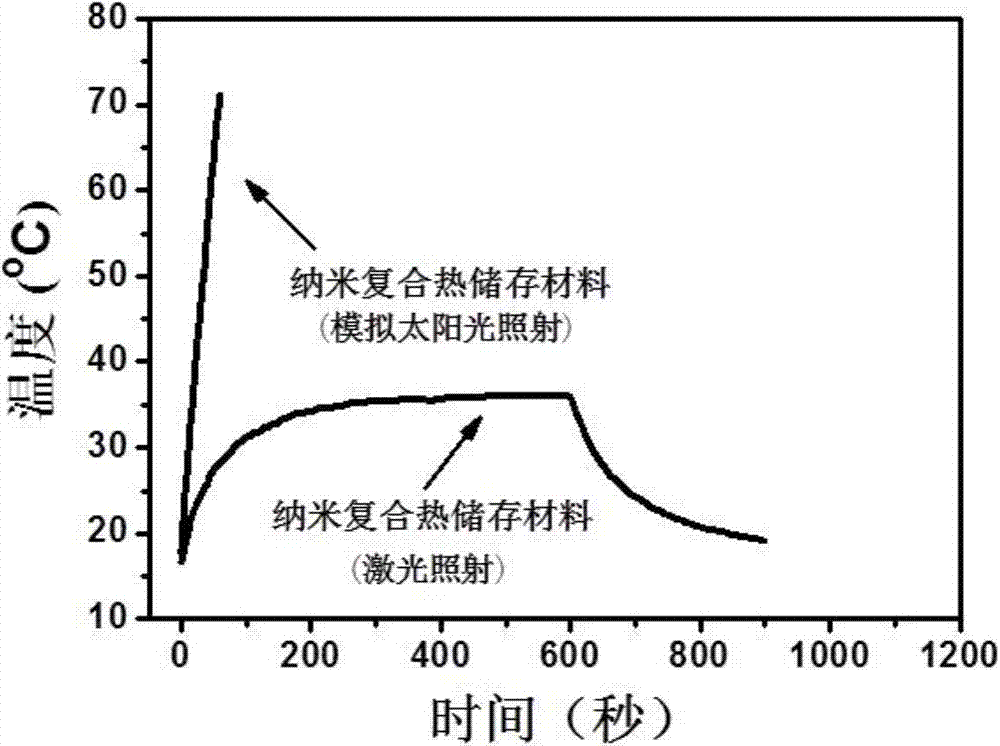

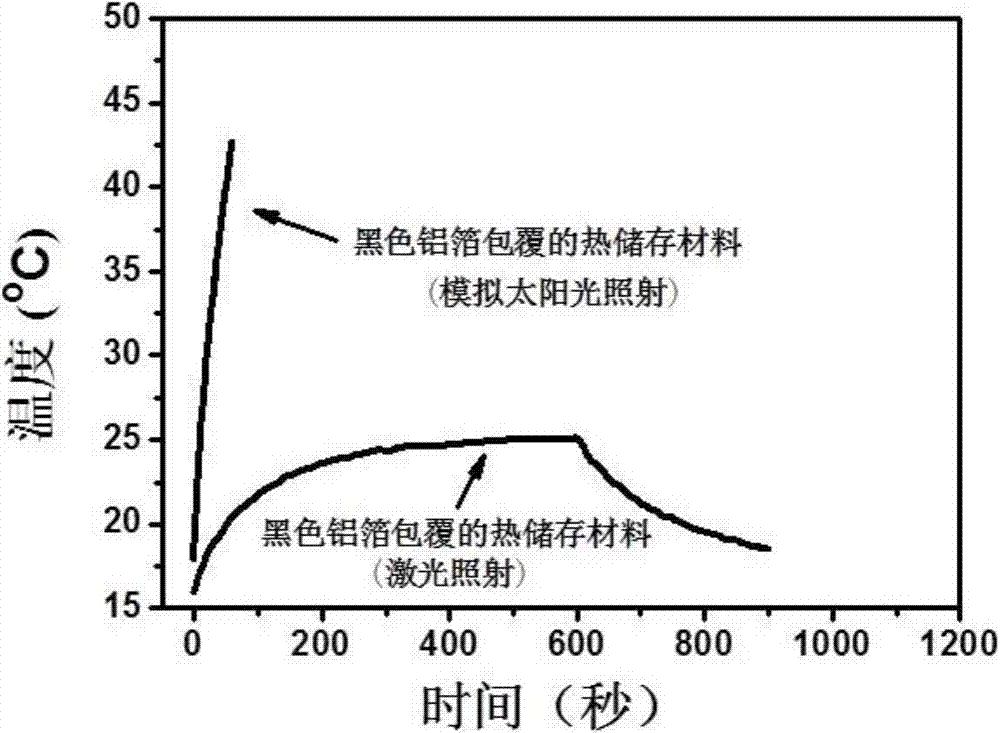

[0028] (4) Use the light-to-heat...

Embodiment 2

[0033] (1) Preparation of gold nanoparticles

[0034] According to the recipe requirements, HAuCl 4 Dissolve in toluene by ultrasonic, add part of oleylamine, heat and stir, then pass nitrogen atmosphere and cold water to reflux, after the reaction is complete, add methanol n-hexane mixed solution to the mixed solution and centrifuge at a high speed, remove the supernatant, and the obtained The nanoparticles were redispersed in toluene, and the particle size of the nanoparticles was about 10±2nm.

[0035] (2) Surface modification of gold nanoparticles

[0036] Add a certain amount of polydimethylsilane macromolecules with mercapto groups to the gold nanoparticle dispersion solution obtained above, heat and stir, and reflux for 12 hours with nitrogen gas, and add methanol to the reacted solution The modified gold nanoparticles were precipitated and re-dispersed in toluene solvent after high-speed centrifugation.

[0037] (3) Preparation of nanocomposite heat storage material...

Embodiment 3

[0042] The preparation method of heat storage composite materials based on the electromagnetic wave absorption of nanoparticles, uniformly disperses nanoparticles with plasmon resonance absorption characteristics into the heat storage material matrix to prepare nanocomposite heat storage materials, specifically through the surface modification of nanoparticles, in heat storage materials The controllable dispersion in the matrix is prepared by the following steps:

[0043] (1) Surface modification process: uniformly disperse the carbon nanotubes with electromagnetic wave absorption characteristics into the ethanol solvent, then add the above mixed solution into the carboxyl-polyethylene glycol surface modification active agent solution to obtain a precipitate, and use the solvent after centrifugation Rinse and finally redisperse in solvent;

[0044] (2) Dispersion process: Mix the obtained surface-modified carbon nanotube solution with silicone oil, continue heating and stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com