Environmentally friendly adhesive remover

An environmentally friendly, glue technology, applied in the field of cleaning agents, can solve the problems of dermatitis and eczema, large investment, environmental hazards, etc., and achieve the effects of easy production and storage, safe use and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

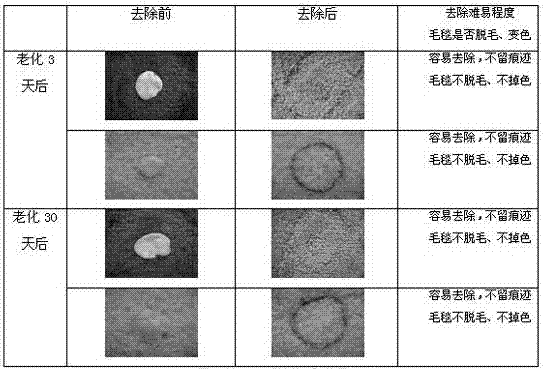

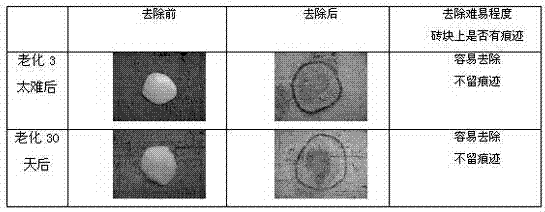

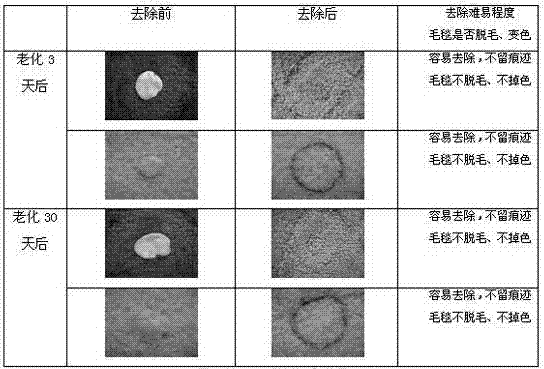

Image

Examples

Embodiment 1

[0045] Take 30 kg of D-limonene, 7 kg of a mixture of N, N-bis(hydroxyethyl) cocamide, amine soap and diethanolamine (N, N-bis(hydroxyethyl) cocamide, amine soap and diethanolamine The mixture is to buy the existing finished product), the carbon chain length is 10-12, 3.5 kg of lauryl alcohol alkoxylate, 0.3 kg of dodecyl dimethyl amine oxide, 12 kg of dipropylene glycol butyl ether and 47.2 kg of water, The raw materials are made into detergent products according to the above-mentioned preparation method.

Embodiment 2

[0047] Take 45 kg of D-limonene, 10 kg of a mixture of N, N-bis(hydroxyethyl) cocamide, amine soap and diethanolamine (N, N-bis(hydroxyethyl) cocamide, amine soap and diethanolamine The mixture is to buy the existing finished product), the carbon chain length is 10-12, 5 kg of lauryl alcohol alkoxylate, 0.5 kg of dodecyl dimethyl amine oxide, 15 kg of dipropylene glycol butyl ether and 24.5 kg of water, The raw materials are made into detergent products according to the above-mentioned preparation method.

Embodiment 3

[0049] Take 50 kg of D-limonene, 18 kg of a mixture of N, N-bis (hydroxyethyl) cocamide, amine soap and diethanolamine (N, N-bis (hydroxyethyl) cocamide, amine soap and diethanolamine The mixture is to buy the existing finished product), the carbon chain length is 10-12, 4 kg of lauryl alcohol alkoxylate, 0.6 kg of dodecyl dimethyl amine oxide, 12 kg of dipropylene glycol butyl ether and 15.4 kg of water, The raw materials are made into detergent products according to the above-mentioned preparation method.

[0050] Design of the present invention is as follows:

[0051] The stickiness of chewing gum comes from ethylene-vinyl acetate copolymer and polyisobutylene, so that these polymers can be swollen and dissolved to remove the chewing gum residue.

[0052] The process of polymer dissolution is the process of molecular movement, solvent molecules penetrate into the polymer, and polymer molecules diffuse into the solvent. This process goes through two stages. First, the solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com