Foaming drainage agent resisting methanol, condensate oil and high salinity

A technology of foam drainage agent and anti-condensate oil, which is applied in the field of foam drainage agent and foam drainage agent for natural gas well drainage and gas recovery. It can solve the problems of failure, foaming ability and stability of foam drainage agent, and achieve salt resistance. Moderate ability, good corrosion inhibition ability, strong foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides an anti-methanol, anti-condensate, anti-high salinity foam drainage agent, the foam drainage agent is composed of various nonionic surfactants, anionic surfactants, amphoteric surfactants, Compounded with resist and pure water;

[0033] A variety of nonionic surfactants include polyether surfactants fatty alcohol polyoxyethylene ether (chemical name: AEO-9) and alkyl alcohol ether carboxylate (chemical name: AEC); anionic surfactants include Sodium lauryl sulfate (chemical name: K-12) and Jimmy’s cationic surfactant; the amphoteric surfactant is dodecyl dimethyl betaine (chemical name: BS-12); the drag reducer is poly Ethylene glycol (chemical name: PEG6000).

[0034] The content of each component in the above-mentioned foam drainage agent is as follows by mass percentage:

[0035] Fatty alcohol polyoxyethylene ether: 3%-5%; Alkyl alcohol ether carboxylate: 5%-10%; Sodium lauryl sulfate: 5%-10%; Jimmy cationic surfactant: 10%- 20%; lauryl dim...

Embodiment 2

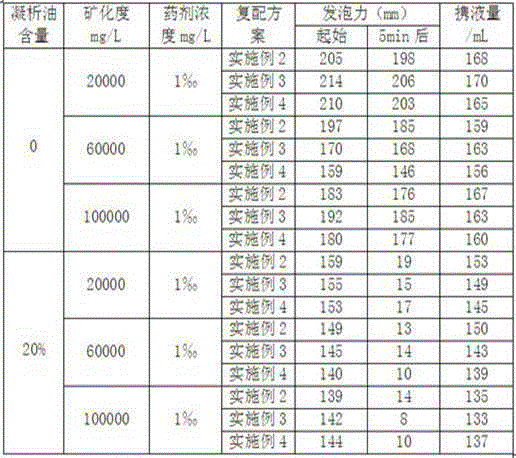

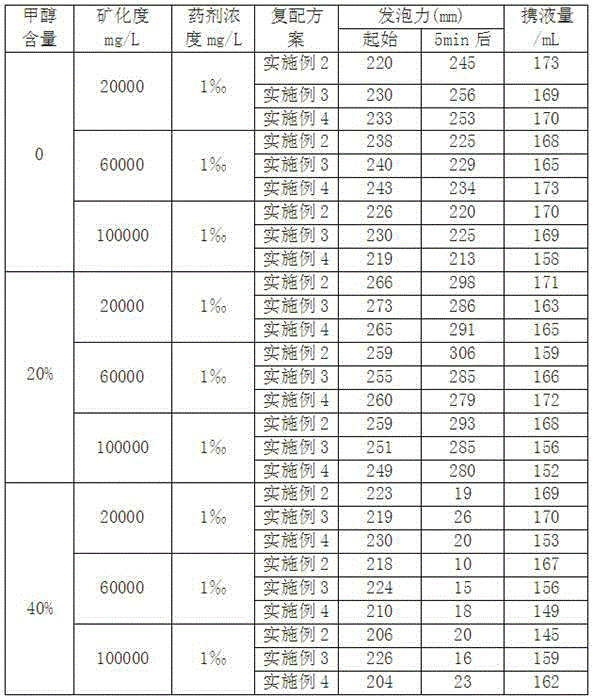

[0038] Add 3% mass fraction of fatty alcohol polyoxyethylene ether AEO-9, 7% mass fraction of alkyl alcohol ether carboxylate AEC, 6% mass fraction of sodium lauryl sulfate K in a reactor with agitator -12, 14% mass fraction of Jimmy cationic surfactant (Here, the Jimmy phosphate double-headed surfactant of Henan Daochun Chemical Technology Co., Ltd.), 45% mass fraction of dodecyl dimethyl beet Base BS-12, 5% by mass fraction of polyethylene glycol PEG6000 and 20% by mass fraction of pure water, stirred for 30 minutes until completely dissolved, and then the foam discharge agent for drainage and gas recovery was obtained. After 24 hours of high-temperature aging, the foam volume was tested using the stirring method.

Embodiment 3

[0040] According to the method of Example 2, the amount of each raw material component of the foam drainage agent in this example is as follows:

[0041] Fatty alcohol polyoxyethylene ether: 5%;

[0042] Alkyl alcohol ether carboxylate: 5%;

[0043] Sodium lauryl sulfate: 10%;

[0044] Jimmy cationic surfactant: 10%;

[0045] Lauryl dimethyl betaine: 50%;

[0046] Polyethylene glycol: 5%;

[0047] Pure water: 15%;

[0048] Total: 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com