Foaming agent used in composite-foam oil flooding

A composite foam and foaming agent technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as the limitation of air flooding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention is realized in the following ways,

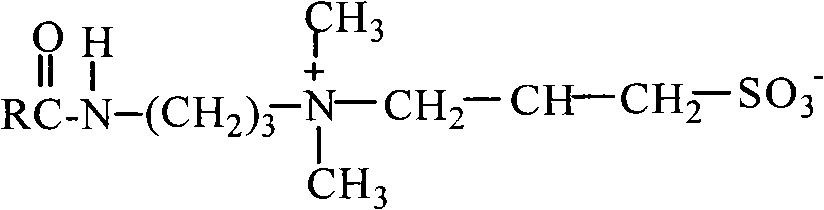

[0027] 1. Mix 0.2% hydroxysultaine and 0.05% lauryl alcohol in proportion, add into formation water during the stirring process, until completely dissolved, and make base liquid.

[0028] 2. While stirring, add 0.1% 1227 to the base liquid to form a foaming agent solution.

[0029] The performance of the foaming agent solution was tested, and the temperature resistance can be stabilized at 50°C; the salt resistance is good, reaching 80×10 3 mg / L; use the Ross-mils method (pouring method) to measure the foaming performance and foam stabilizing performance of the foaming agent. The measured foaming height is 14.4cm, and the half-life reaches 16 hours; the oil-water interfacial tension is 0.194mN / m.

Embodiment 2

[0031] The present invention is realized in the following ways,

[0032] 1. Mix 0.4% hydroxysultaine and 0.1% lauryl alcohol in proportion, add into formation water during stirring, until completely dissolved, and make base liquid.

[0033] 2. While stirring, add 0.1% 1227 to the base liquid to form a foaming agent solution.

[0034] The performance of the foaming agent solution was tested, and the temperature resistance can be stabilized at 50°C; the salt resistance is good, reaching 80×10 3 mg / L; use the Ross-mils method (pouring method) to measure the foaming performance and foam stabilizing performance of the foaming agent. The measured foaming height is 14.4cm, and the half-life reaches 16 hours; the oil-water interfacial tension is 0.194mN / m.

Embodiment 3

[0036] The present invention is realized in the following ways,

[0037] 1. Mix 0.3% hydroxysultaine and 0.07% dodecanol in proportion, add into formation water during stirring, until completely dissolved, and make base liquid.

[0038] 2. While stirring, add 0.1% 1227 to the base liquid to form a foaming agent solution.

[0039] The performance of the foaming agent solution was tested, and the temperature resistance can be stabilized at 50°C; the salt resistance is good, reaching 80×10 3 mg / L; use the Ross-mils method (pouring method) to measure the foaming performance and foam stabilizing performance of the foaming agent. The foaming height measured is 14.4cm, and the half-life reaches 16 hours; the oil-water interfacial tension is 0.194mN / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com