Carbon dioxide foam stabilizer suitable for low-permeability oil deposit

A foam stabilizer and carbon dioxide technology, applied in the field of foam stabilizers, can solve the problems of affecting foam stability, unsatisfactory amplitude, poor shear resistance and high temperature resistance of polymers, etc. Good cut, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, stirring method measure the foam stabilizing performance of foam stabilizer: in order to further strengthen the stability of foam, carried out foam stabilizer measurement experiment, whipping agent GP (sodium dodecylbenzene sulfonate) use mass concentration is 0.9 %, test environment PH=3, the mass concentration that foam stabilizer (by mass ratio 4:1:1 is made up of modified guar gum, hydroxyethyl cellulose, lauryl alcohol) uses is 0.6%, when measuring, 100ml Pour the prepared solution into a transparent measuring cup with a stirrer and scale, stir at high speed (3000 rpm) for 60s, record the foam volume and the time when half the liquid volume is separated from the foam and the time when the foam is reduced to half, the former Indicates foaming ability (foaming volume), and the latter two represent foam stability (half-life). The experimental results are shown in Table 1.

[0013] Foaming volume and half-life of foaming agent Table 1

[0014] ...

Embodiment 2

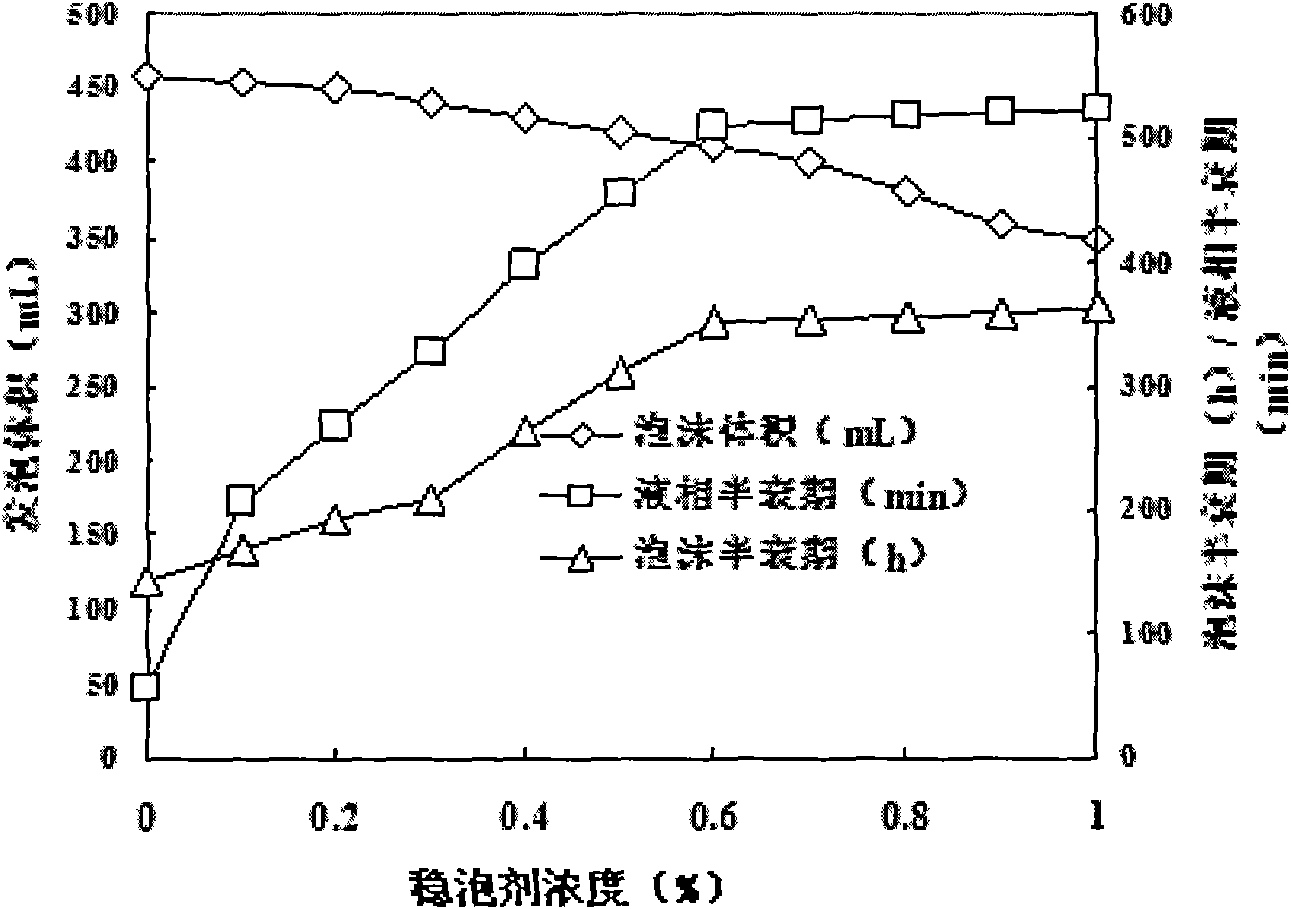

[0017] Implementation example 2, in the preferred experiment of foam stabilizer, draw through comparative analysis, modified guar gum, hydroxyethyl cellulose, lauryl alcohol are more effective after compounding, and the ratio of its mass is 4: 1: 1 works best. In the stabilizer concentration test, foaming agent GP (sodium dodecylbenzenesulfonate) use concentration is 0.9%, when test environment PH=3, foam stabilizer (represented by modified guar gum, hydroxyethyl cellulose , lauryl alcohol is formed by mass ratio 4: 1: 1) when the mass concentration is 0.6%, the comprehensive effect of all aspects is the best, and the experimental results are shown in figure 1 .

Embodiment 3

[0018] Example 3. Performance evaluation of the foam profile control system: The water samples of the No. 8 Oil Production Plant were taken, and the foam profile control system was prepared with the foam stabilizer of the present invention. The experimental results are shown in Table 2 below:

[0019] Comprehensive performance table of foam profile control agent Table 2

[0020]

[0021] The experimental results show that the foaming volume of the system reaches 400mL when the oil saturation reaches 60% in the clean water configuration and the sewage configuration, and the foam half-life reaches 83h, which shows that the system is not affected by salinity and oil saturation and is stable. The foam stabilization effect of the agent is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com