Method for generating functionalized nano zinc oxide-graphene on surfaces of aramid fibers

A nano-zinc oxide and aramid fiber technology, applied in the field of clothing fibers, can solve the problems of lack of modification methods and the inability to involve in the field of high-tech functional materials, etc., to improve the aging resistance to sunlight, improve UV weather resistance, and smoke suppression performance noticeable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

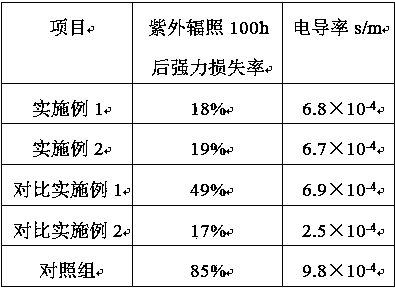

Examples

Embodiment 1

[0026] A method for generating functionalized nano-zinc oxide-graphene on the surface of aramid fiber, is characterized in that, comprises the steps:

[0027] (1) Aramid fiber surface activation modification treatment:

[0028] Dissolve 4 parts of polymethylene polyphenyl polyisocyanate and 1 part of epoxy resin in 45 parts of toluene, stir and disperse evenly, immerse the pretreated aramid fiber in it for 1 hour, remove the excess solution on the surface, and place it at 145- After drying at 155°C for 110s to evaporate the solvent, activate the reaction at 215-225°C for 115s to obtain aramid fiber with surface activation modification treatment;

[0029] (2) Phosphoric acid-melamine polyphosphate flame retardant modified aramid fiber:

[0030] Immerse the surface-activated modified aramid fiber obtained in (1) in a phosphoric acid solution at a bath ratio of 1:20 for 4 minutes, and then soak it in a hot saturated aqueous solution of melamine polyphosphate at 80-85°C at a bath...

Embodiment 2

[0041] A method for generating functionalized nano-zinc oxide-graphene on the surface of aramid fiber, is characterized in that, comprises the steps:

[0042] (1) Aramid fiber surface activation modification treatment:

[0043] Dissolve 8 parts of polymethylene polyphenyl polyisocyanate and 2 parts of epoxy resin in 90 parts of toluene, stir and disperse evenly, immerse the pretreated aramid fiber in it for 2 hours, remove the excess solution on the surface, and put it in 145- After drying at 155°C for 130s to evaporate the solvent, activate the reaction at 215-225°C for 125s to obtain aramid fiber with surface activation modification treatment;

[0044] (2) Phosphoric acid-melamine polyphosphate flame retardant modified aramid fiber:

[0045]Immerse the surface-activated modified aramid fiber obtained in (1) in a phosphoric acid solution at a bath ratio of 1:20 for 5 minutes, and then soak it in a hot saturated aqueous solution of melamine polyphosphate at 80-85°C at a bath ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com