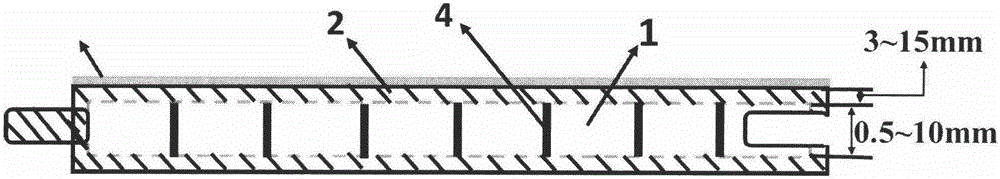

Novel energy saving hollow exterior wall decorative plate and manufacture method thereof

A decorative panel and hollow technology, which is applied to buildings, building structures, floors, etc., can solve problems such as poor thermal insulation and sound insulation performance and large specific gravity, and achieve the effects of enhancing UV resistance, reducing costs, and increasing aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

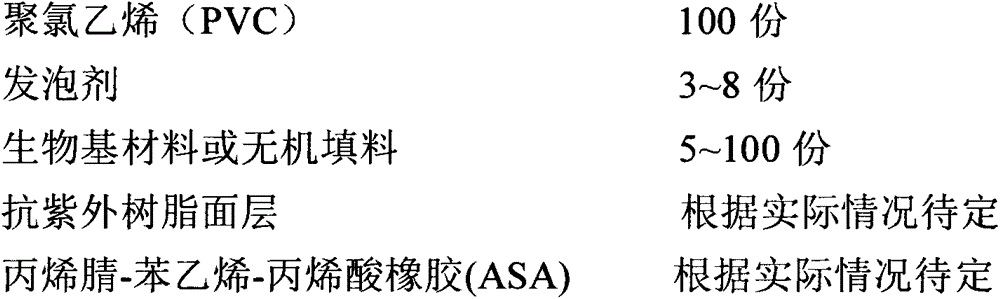

Embodiment 1

[0015] Weigh 10Kg of polyvinyl chloride, 0Kg of wood powder, and 0.3Kg of AC foaming agent and mix them in a high-speed mixer for 20 minutes. The mixed samples were extruded through a hollow sheet extruder and a 0.8 mm top layer of ASA was co-extruded. The resulting boards are cut into squares to facilitate construction and transportation.

Embodiment 2

[0017] Weigh 10Kg of polyvinyl chloride, 2Kg of wood powder, and 0.8Kg of DPT foaming agent and mix them in a high-speed mixer for 10 minutes. The mixed samples were extruded through a hollow sheet extruder and co-extruded with a 2 mm face layer of PMMA. The resulting boards are cut into rectangles to facilitate construction and transportation.

Embodiment 3

[0019] Weigh 20Kg of polyvinyl chloride, 3Kg of straw powder, and 0.4Kg of AC foaming agent and mix them in a high-speed mixer for 20 minutes. The mixed samples were extruded through a hollow sheet extruder and a 0.5 mm top layer of ASA was co-extruded. The resulting boards are cut into waves to facilitate construction and transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com