Preparing method for uvioresistant high-strength composite material

A composite material, high-strength technology, applied in coatings and other directions, to achieve the effect of improving UV resistance, unique process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

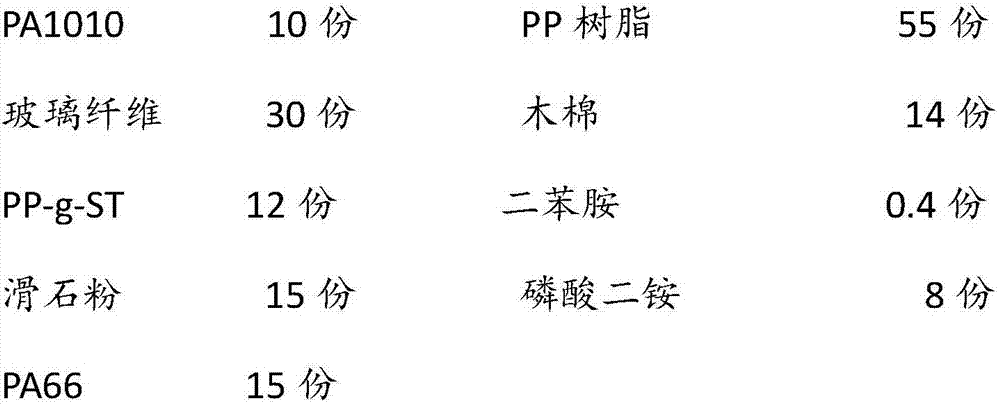

[0030] Anti-ultraviolet high-strength composite material, the composite material includes by weight:

[0031]

[0032] Preparation method of UV-resistant high-strength composite material:

[0033] Weigh PA66, PA1010, PP resin, glass fiber, kapok, PP-g-ST, diphenylamine, talcum powder and diammonium phosphate according to mass components;

[0034] Place the weighed PA66, PA1010, PP resin, glass fiber, and kapok in a dryer at a temperature of 95°C and a drying time of 40 minutes;

[0035] The dried glass fiber and kapok are placed in a mixer, the mixing speed is 450r / min, and the mixing time is 4min to obtain the mixture a, which is set aside;

[0036] Put the dried PA66, PA1010, PP resin, PP-g-ST, diphenylamine, talc powder and diammonium phosphate in a mixer, the mixing speed is 240r / min, and the mixing time is 15min to obtain the mixture b;

[0037] Slowly pour the compound b into the hopper of the twin-screw extruder, control the screw speed to 400r / min, and control the...

Embodiment 2

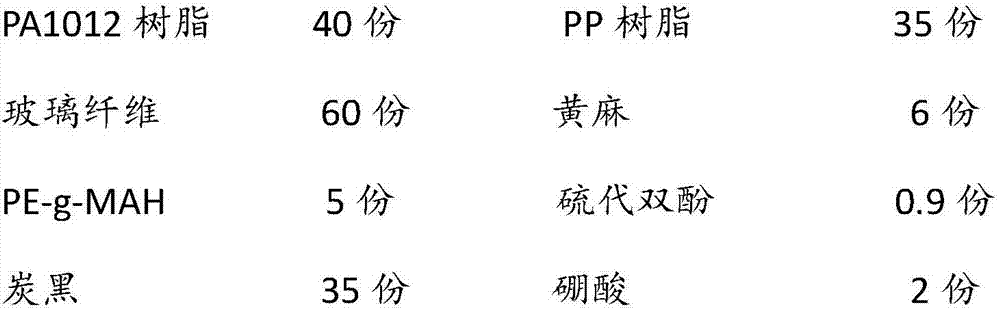

[0043] Anti-ultraviolet high-strength composite material, the composite material includes by weight:

[0044]

[0045] Preparation method of UV-resistant high-strength composite material:

[0046] Weigh PA1012 resin, PP resin, glass fiber, jute, PE-g-MAH, thiobisphenol, carbon black and boric acid according to mass components;

[0047] Place the weighed PA1012 resin, PP resin, glass fiber, and jute in a dryer at a temperature of 80°C and a drying time of 70 minutes;

[0048] The dried glass fiber and jute are placed in a mixer, the mixing speed is 300r / min, and the mixing time is 9min to obtain the mixed material a for subsequent use;

[0049] Put the dried PA1012 resin, PP resin, PE-g-MAH, thiobisphenol, carbon black and boric acid in a mixer, the mixing speed is 180r / min, and the mixing time is 25min to obtain the mixture b;

[0050] Slowly pour the compound b into the hopper of the twin-screw extruder, control the screw speed to 300r / min, and control the temperature of...

Embodiment 3

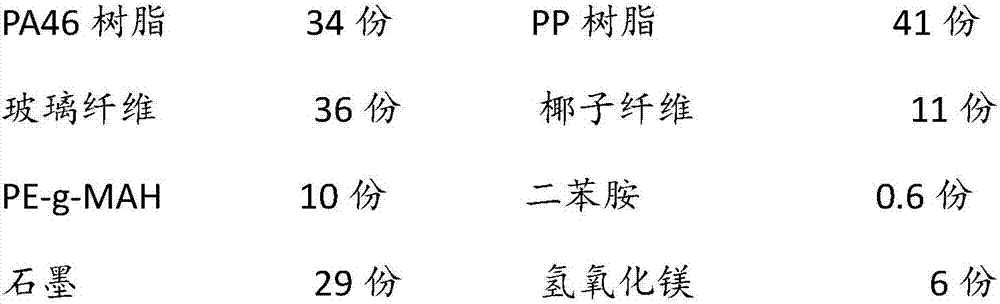

[0056] Anti-ultraviolet high-strength composite material, the composite material includes by weight:

[0057]

[0058] Preparation method of UV-resistant high-strength composite material:

[0059] Weigh PA46 resin, PP resin, glass fiber, coconut fiber, PE-g-MAH, diphenylamine, graphite and magnesium hydroxide according to mass components;

[0060] Place the weighed PA46 resin, PP resin, glass fiber, and coconut fiber in a dryer at a temperature of 92°C and a drying time of 51 minutes;

[0061] The dried glass fiber and coconut fiber are placed in a mixer, the mixing speed is 410r / min, and the mixing time is 5min to obtain the mixed material a for subsequent use;

[0062] Put the dried PA46 resin, PP resin, PE-g-MAH, diphenylamine, graphite and magnesium hydroxide in a mixer, the mixing speed is 230r / min, and the mixing time is 17min to obtain the mixture b;

[0063] Slowly pour the compound b into the hopper of the twin-screw extruder, control the screw speed to 330r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com