Processing technology of silkworm pupa protein lycra plain cloth

A processing technology, silkworm chrysalis protein technology, applied in textiles, fabrics, multi-strand fabrics, etc., can solve problems such as poor gloss, monotonous patterns, and small elasticity, and achieve the effect of increasing the anti-ultraviolet function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

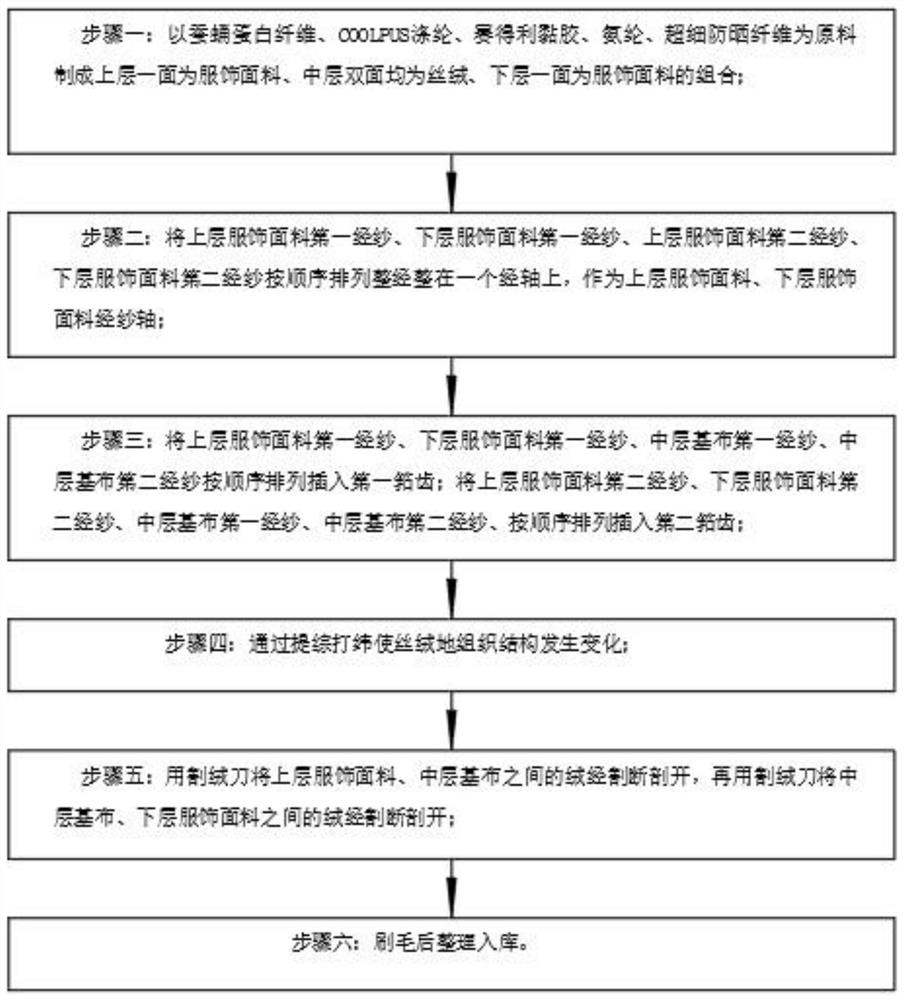

[0026] see figure 1 , the present invention provides a technical solution: a silkworm chrysalis protein stretcher plain weave processing technology, comprising the following steps:

[0027] Step 1: Use silkworm chrysalis protein fiber, COOLPUS polyester, Sateri viscose, spandex, and ultra-fine sunscreen fiber as raw materials to make a combination of clothing fabric on one side of the upper layer, velvet on both sides of the middle layer, and clothing fabric on the bottom layer;

[0028] Step 2: Arranging and warping the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the second warp yarn of the upper garment fabric, and the second warp yarn of the lower garment fabric on one warp beam as the upper garment fabric and the lower garment fabric fabric warp beam;

[0029] Step 3: Arrange the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the first warp yarn of the middle base fabric, and ...

Embodiment 2

[0039] see figure 1 , the present invention provides a technical solution: a silkworm chrysalis protein stretcher plain weave processing technology, comprising the following steps:

[0040] Step 1: Use silkworm chrysalis protein fiber, COOLPUS polyester, Sateri viscose, spandex, and ultra-fine sunscreen fiber as raw materials to make a combination of clothing fabric on one side of the upper layer, velvet on both sides of the middle layer, and clothing fabric on the bottom layer;

[0041] Step 2: Arranging and warping the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the second warp yarn of the upper garment fabric, and the second warp yarn of the lower garment fabric on one warp beam as the upper garment fabric and the lower garment fabric fabric warp beam;

[0042] Step 3: Arrange the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the first warp yarn of the middle base fabric, and ...

Embodiment 3

[0052] see figure 1 , the present invention provides a technical solution: a silkworm chrysalis protein stretcher plain weave processing technology, comprising the following steps:

[0053] Step 1: Use silkworm chrysalis protein fiber, COOLPUS polyester, Sateri viscose, spandex, and ultra-fine sunscreen fiber as raw materials to make a combination of clothing fabric on one side of the upper layer, velvet on both sides of the middle layer, and clothing fabric on the bottom layer;

[0054] Step 2: Arranging and warping the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the second warp yarn of the upper garment fabric, and the second warp yarn of the lower garment fabric on one warp beam as the upper garment fabric and the lower garment fabric fabric warp beam;

[0055] Step 3: Arrange the first warp yarn of the upper garment fabric, the first warp yarn of the lower garment fabric, the first warp yarn of the middle base fabric, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com