Method for improving ultraviolet resistance of POB fibers by using bifunctional hyperbranched siloxane

A siloxane and bifunctional technology, which is applied in the field of improving the UV resistance and adhesion of PBO fibers, can solve the problems of poor adhesion of the resin matrix interface, easy to be damaged by light, and low UV resistance of PBO fibers, and achieves low price. , Enhanced UV resistance and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

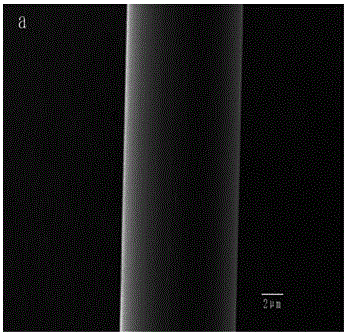

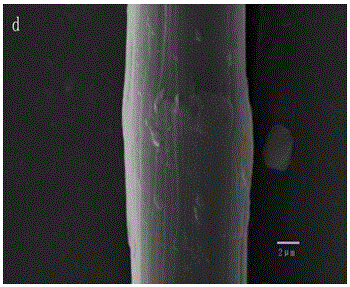

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the method that hyperbranched siloxane provided in this embodiment improves the anti-ultraviolet performance of PBO fiber is carried out through the following steps:

[0027] 1. PBO fiber pretreatment:

[0028] (1) Use a Soxhlet extractor to extract the PBO fiber first to remove surface impurities. The specific steps are: wrap a certain quality of PBO fiber wrapped on a glass slide with filter paper, and add it to the Soxhlet extractor, add Acetone carries out extraction 48h;

[0029] (2) After the extraction is completed, wash and dry, then add to the solution of epichlorohydrin and acetone (the volume ratio of epichlorohydrin and acetone is 1:5), and then carry out the intensity of 40kGy -ray radiation treatment for 30 minutes to obtain pretreated PBO fibers, that is, epichlorohydrin grafted PBO fibers.

[0030] Two, the preparation of difunctional hyperbranched siloxane:

[0031] (1) Add KH560, KH570 and water into a three-necked flask, a...

specific Embodiment approach 2

[0042] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of KH560, KH570 and water in step 2 is (KH560+KH570):H2O=1:1.3. Others are the same as the first embodiment.

[0043] The PBO fiber coated with hyperbranched siloxane obtained in this embodiment and the PBO fiber in step 1 were irradiated with 1000W ultraviolet light for 20s, and then the fiber monofilament pull-out test was performed. The comparison of the two shows that the tensile strength of the PBO fiber precursor in step one is 4.91GPa, and the tensile strength of the PBO fiber in the step one irradiated by ultraviolet light is 4.27GPa; The tensile strength of PBO fiber is 4.73GPa after ultraviolet light irradiation, and the anti-ultraviolet performance has been greatly improved.

specific Embodiment approach 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: in step 2, heat to 70° C. for 4.5 hours. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com