Anti-ultraviolet polyester-cotton fabric and preparation method thereof

An anti-ultraviolet and anti-ultraviolet technology, which is applied in the field of knitted fabrics, can solve the problems of uneven anti-ultraviolet performance and air permeability of fabrics, reduce the immune function of organisms, and easily get diseases, etc., achieve good thermal and oxygen aging resistance, improve Anti-ultraviolet performance, effect of improving heat sublimation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] This case proposes a method for preparing an anti-ultraviolet polyester-cotton fabric, which includes the following steps: degreasing the gray cloth, dyeing, and padding with an anti-ultraviolet finishing agent to obtain an anti-ultraviolet polyester-cotton fabric; the gray cloth is made by blending the following raw materials in parts by weight into:

[0025] 60-70 parts by weight of polyester fiber;

[0026] 30-34 parts by weight of cotton fiber;

[0027] 3-5 parts by weight of bamboo fiber.

[0028] Polyester-cotton refers to the general term for blended fabrics of polyester and cotton. Textiles woven with polyester and cotton blended yarns are common materials for making clothes. Polyester-cotton has good elasticity and wear resistance under dry and wet conditions. Stable, small shrinkage, tall and straight, not easy to wrinkle, easy to wash, quick-drying, but has a strong affinity for oil stains, easy to absorb oil stains, and it is easy to generate static electr...

Embodiment 1

[0042] A preparation method of anti-ultraviolet polyester-cotton fabric, is characterized in that, comprises the steps:

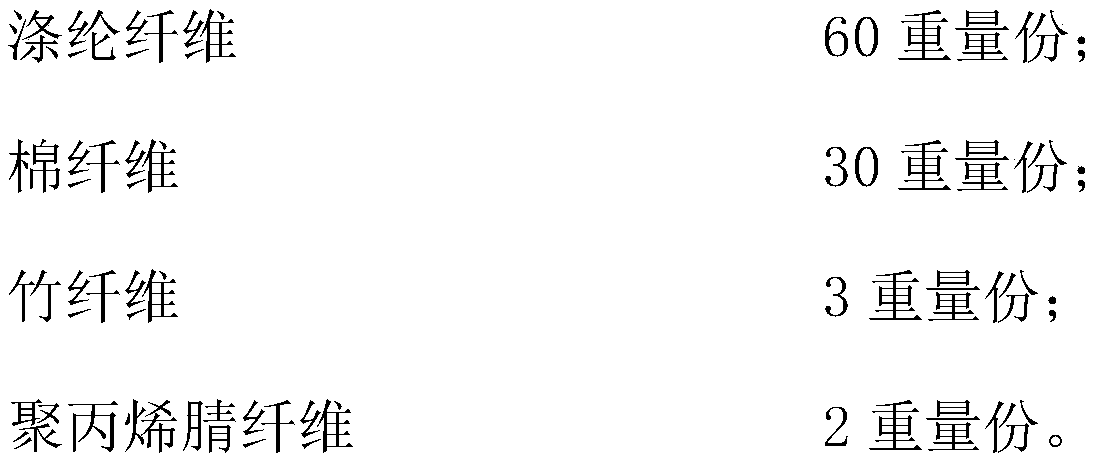

[0043] (1) The gray cloth is blended with polyester fiber and cotton fiber into a blended yarn by a conventional process, and then knitted and woven with the blended yarn, bamboo fiber and polyacrylonitrile fiber using a weft knitting circular machine to obtain a gray cloth. The gray cloth is made by blending the following raw materials in parts by weight:

[0044]

[0045] (2) The gray cloth is smelted continuously for 6 hours with the deoiling treatment liquid under the temperature range of 110℃~115℃ and the pressure of 300kPa~400kPa. The deoiling treatment liquid includes 3% hydrogen peroxide and 15% urethane Tropin, 2% of alkyl dimethyl sulfoethyl betaine and 80% of pure water.

[0046] (3) dyeing, bleaching, whitening and dyeing are carried out according to conventional methods as required;

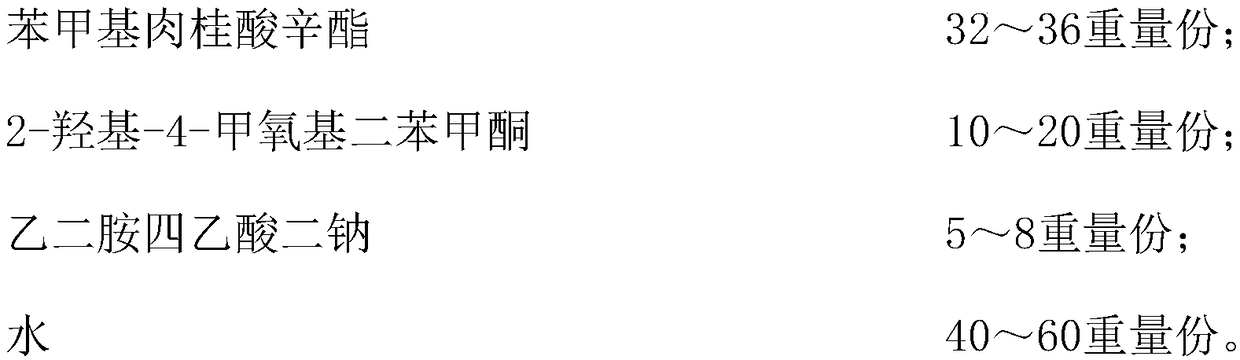

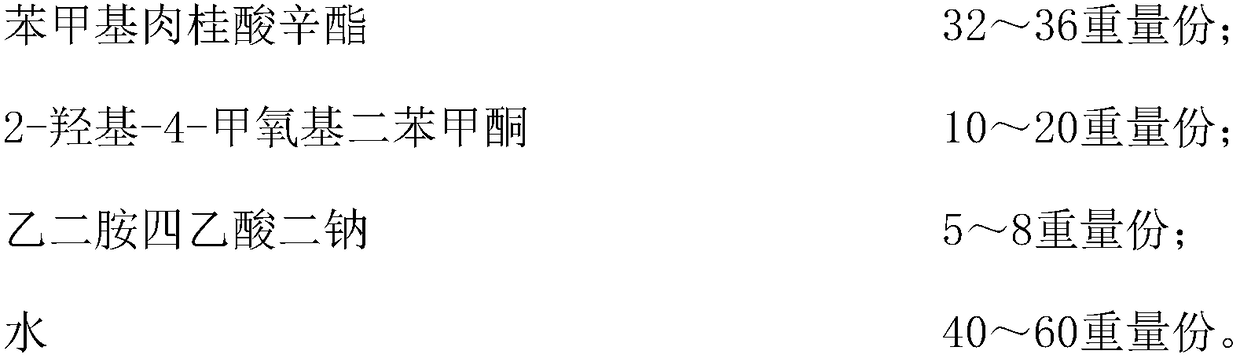

[0047](4) gray cloth padding anti-ultraviolet finishing...

Embodiment 2

[0052] A preparation method for an anti-ultraviolet polyester-cotton fabric, comprising the steps of:

[0053] (1) The gray cloth is blended with polyester fiber and cotton fiber into a blended yarn by a conventional process, and then knitted and woven with the blended yarn, bamboo fiber and polyacrylonitrile fiber using a weft knitting circular machine to obtain a gray cloth. The gray cloth is made by blending the following raw materials in parts by weight:

[0054]

[0055] (2) The gray cloth is smelted continuously for 6 hours with the deoiling treatment liquid under the temperature range of 110℃~115℃ and the pressure of 300kPa~400kPa. The deoiling treatment liquid includes 3% hydrogen peroxide and 15% urethane Tropin, 2% of alkyl dimethyl sulfoethyl betaine and 80% of pure water.

[0056] (3) dyeing, bleaching, whitening and dyeing are carried out according to conventional methods as required;

[0057] (4) gray cloth padding anti-ultraviolet finishing agent obtains an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com