Antibacterial and deodorizing textile fabric and preparation method thereof

A technology for textile fabrics and deodorization, applied in the processing of textile materials, textile and papermaking, rayon manufacturing, etc., can solve the problems of single function, inconvenience, and general comfort of hypoallergenic textiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

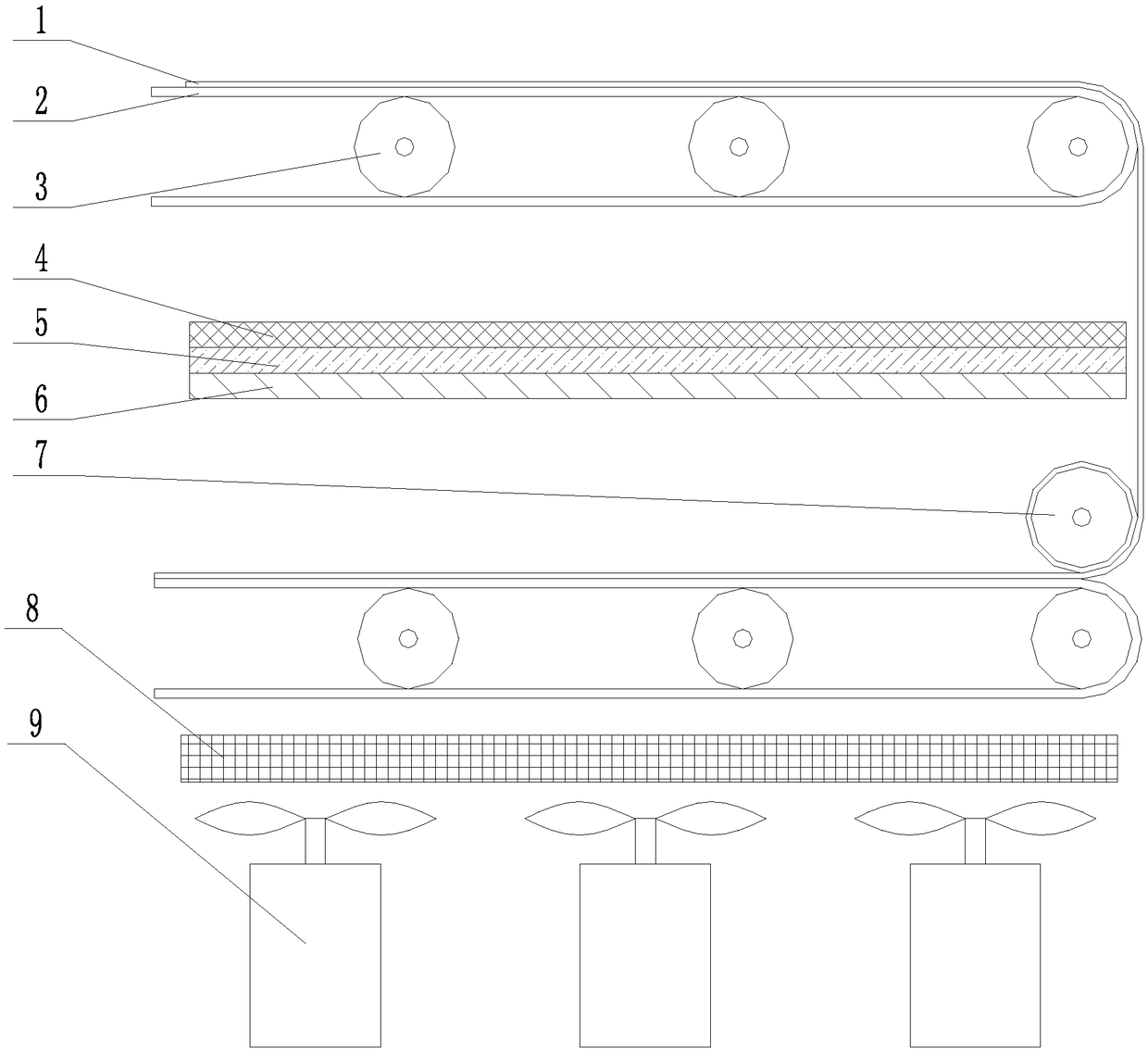

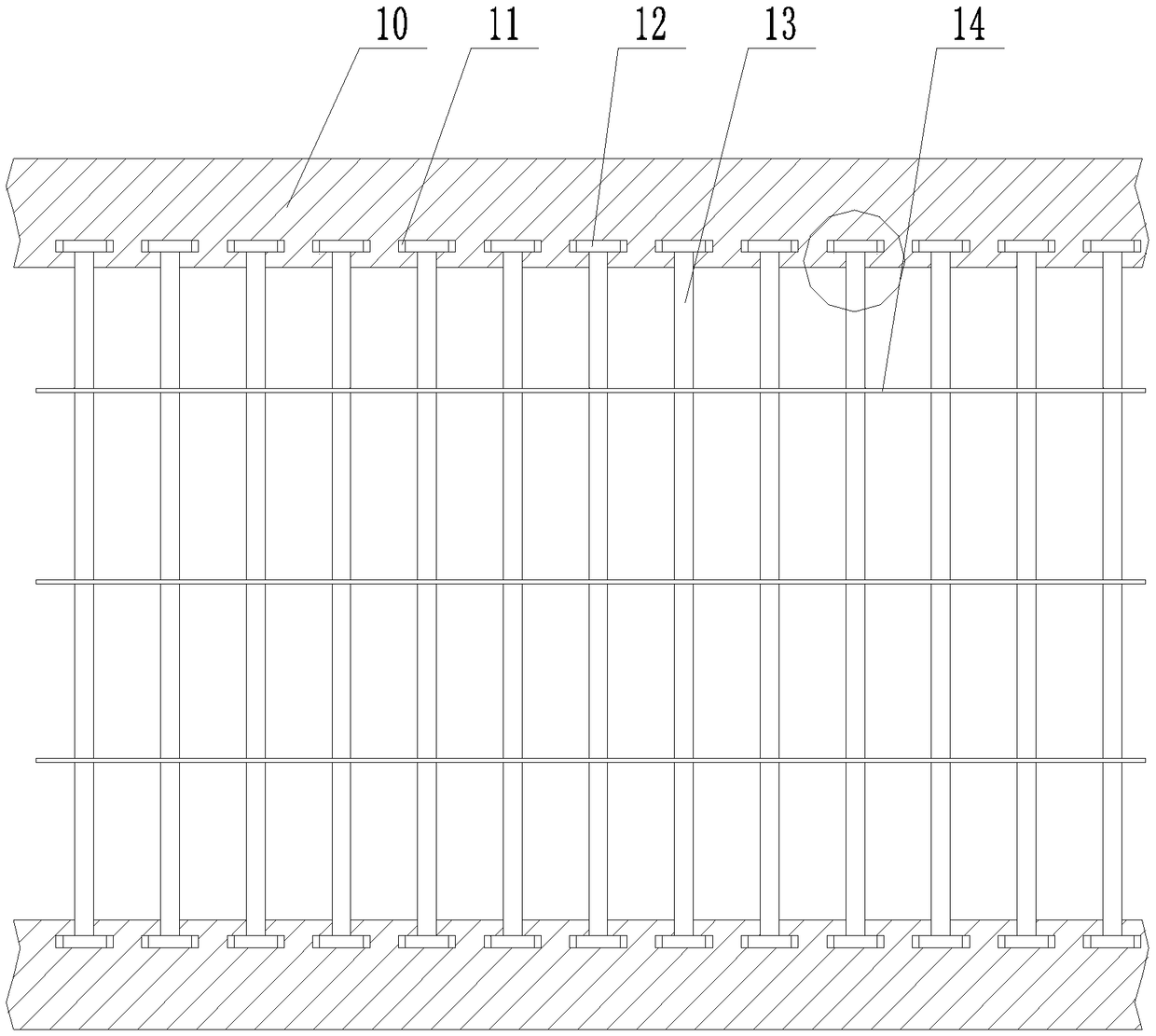

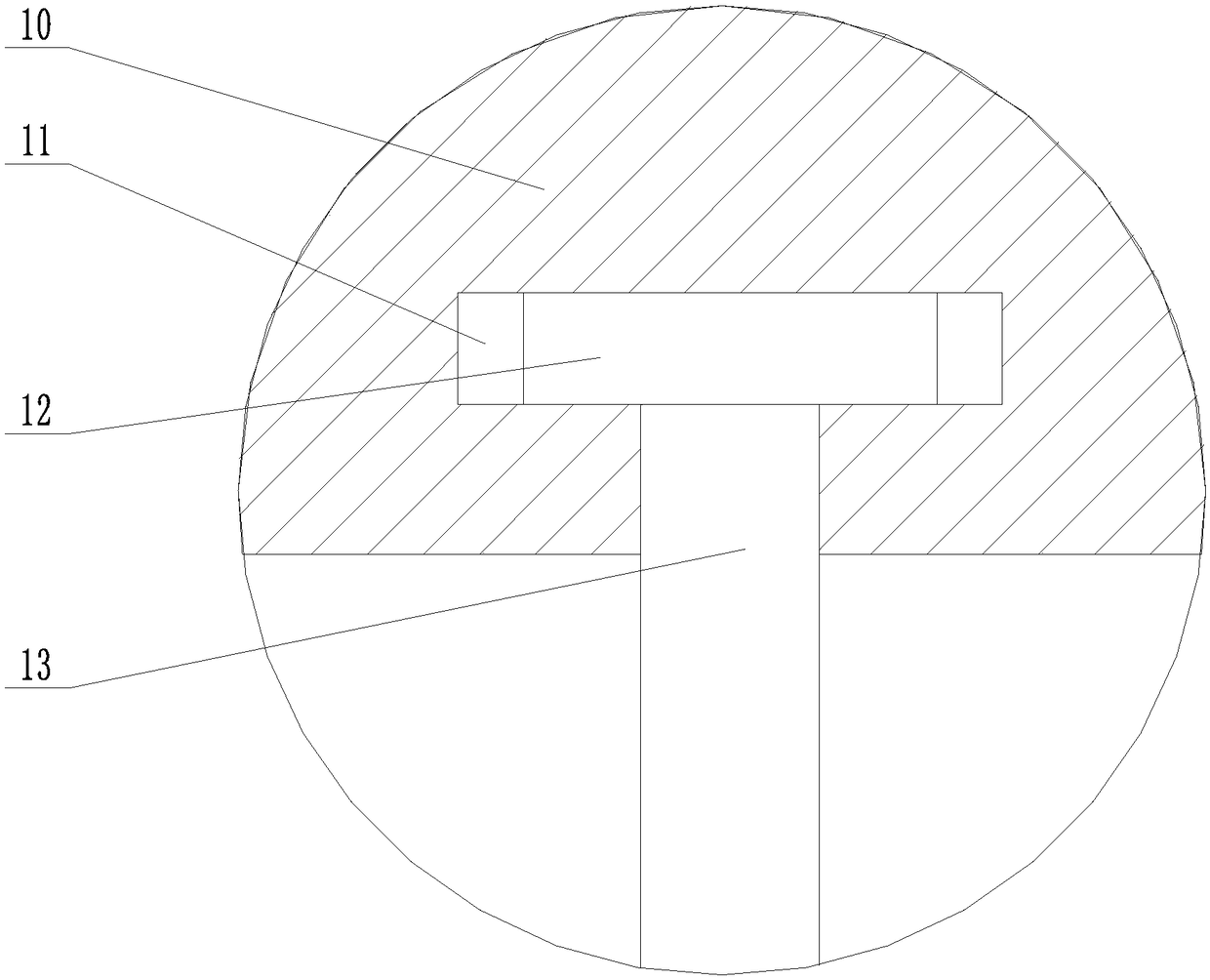

Image

Examples

Embodiment 1

[0040] An antibacterial and deodorant textile fabric, made of the following raw materials in parts by weight: 35 parts of polyvinyl alcohol, 17 parts of chitosan, 16 parts of bamboo fiber, 10 parts of Tai Chi stone powder, 8 parts of honeysuckle, 2 parts of garlic essential oil and a single Layer graphene 4 parts.

[0041] Among them, the diameter of Tai Chi stone powder is 20mm-50mm; the weight average molecular weight of chitosan is 3×10 5 -5×10 5 , The viscosity at 25°C is 0.8-1Pas.

[0042] The specific steps for preparing antibacterial and deodorizing textile fabrics by using the above-mentioned raw materials include:

[0043] S1: Add chitosan and Taichi stone powder to 25 parts by weight of distilled water, stir evenly, then add single-layer graphene-bamboo fiber-polyvinyl alcohol gel, stir for 12 hours, and put it into a twin-screw extruder Blended for 6 minutes, and melt-spun at 180°C to obtain spun fibers;

[0044] Wherein, the preparation method of monolayer grap...

Embodiment 2

[0053] An antibacterial and deodorant textile fabric, made of the following raw materials in parts by weight: 30 parts of polyvinyl alcohol, 15 parts of chitosan, 14 parts of bamboo fiber, 8 parts of Tai Chi stone powder, 5 parts of honeysuckle, 1 part of garlic essential oil and a single Layer graphene 2 parts.

[0054] Among them, the diameter of Tai Chi stone powder is 20mm-50mm; the weight average molecular weight of chitosan is 3×10 5 -5×10 5 , The viscosity at 25°C is 0.8-1Pas.

[0055] The specific steps for preparing antibacterial and deodorizing textile fabrics by using the above-mentioned raw materials include:

[0056] S1: Add chitosan and Taichi stone powder to 20 parts by weight of distilled water, stir evenly, then add single-layer graphene-bamboo fiber-polyvinyl alcohol gel, stir for 12 hours, and put it into a twin-screw extruder Blended for 6 minutes, and melt-spun at 180°C to obtain spun fibers;

[0057] Wherein, the preparation method of monolayer graphe...

Embodiment 3

[0066] An antibacterial and deodorant textile fabric made of the following raw materials in parts by weight: 35 parts of polyvinyl alcohol, 15 parts of chitosan, 16 parts of bamboo fiber, 8 parts of Tai Chi stone powder, 8 parts of honeysuckle, 1 part of garlic essential oil and a single Layer graphene 2 parts.

[0067] Among them, the diameter of Tai Chi stone powder is 20mm-50mm; the weight average molecular weight of chitosan is 3×10 5 -5×10 5 , The viscosity at 25°C is 0.8-1Pas.

[0068] The specific steps for preparing antibacterial and deodorizing textile fabrics by using the above-mentioned raw materials include:

[0069] S1: Add chitosan and Taiji stone powder to 22 parts by weight of distilled water, stir evenly, then add single-layer graphene-bamboo fiber-polyvinyl alcohol gel, stir for 12 hours, and put it into a twin-screw extruder Blended for 6 minutes, and melt-spun at 180°C to obtain spun fibers;

[0070] Wherein, the preparation method of monolayer graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com