Method and device for preparing textile fabric having far infrared radiation energy, and prepared textile fabric

A far-infrared, textile technology, applied in the processing of textile material equipment configuration, textile and papermaking, textile material processing, etc., can solve the problem of skin redness, itching, reduced fiber breaking strength, no effective far infrared emission. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with specific embodiments, and the advantages and characteristics of the present invention will become clearer along with the description. However, these embodiments are only exemplary and do not constitute any limitation to the scope of the present invention. Those skilled in the art should understand that the details and forms of the technical solutions of the present invention can be modified or replaced without departing from the spirit and scope of the present invention, but these modifications and replacements all fall within the protection scope of the present invention.

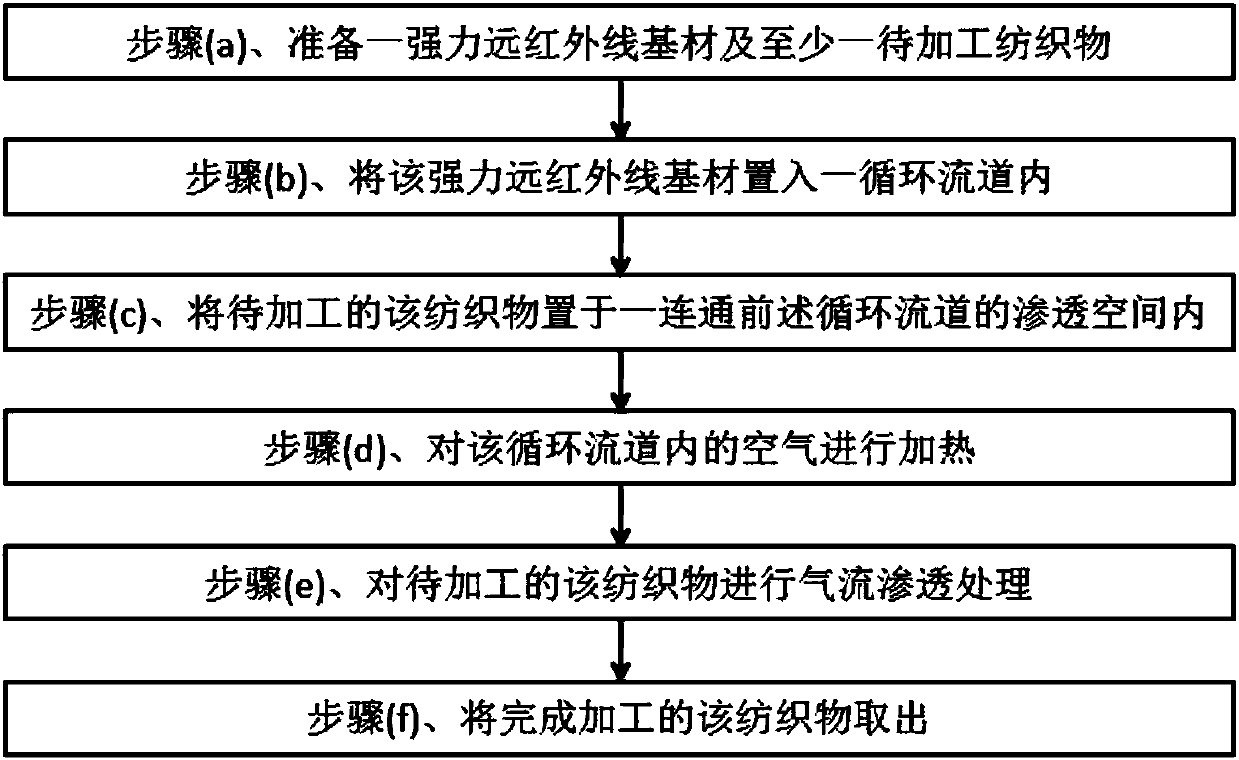

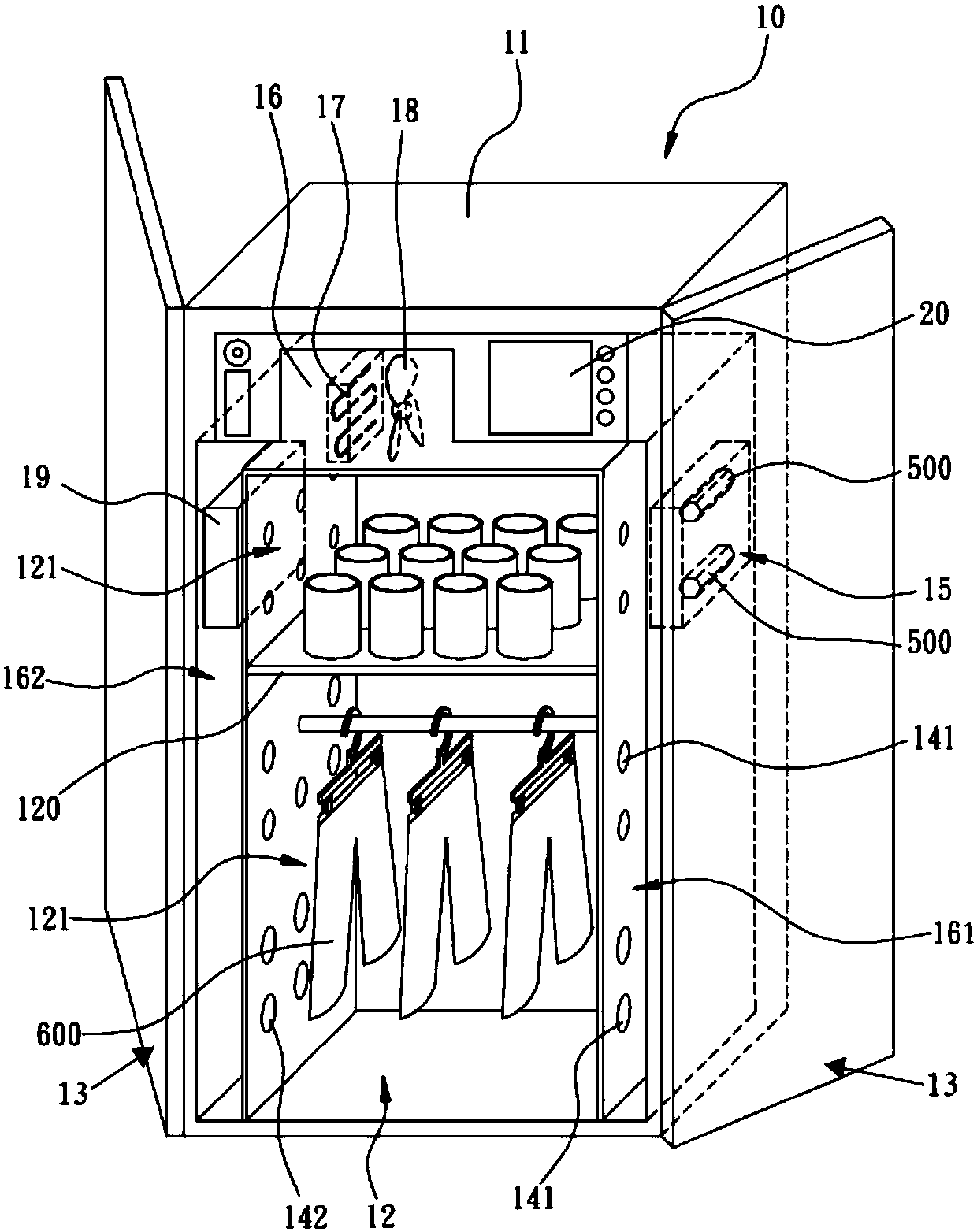

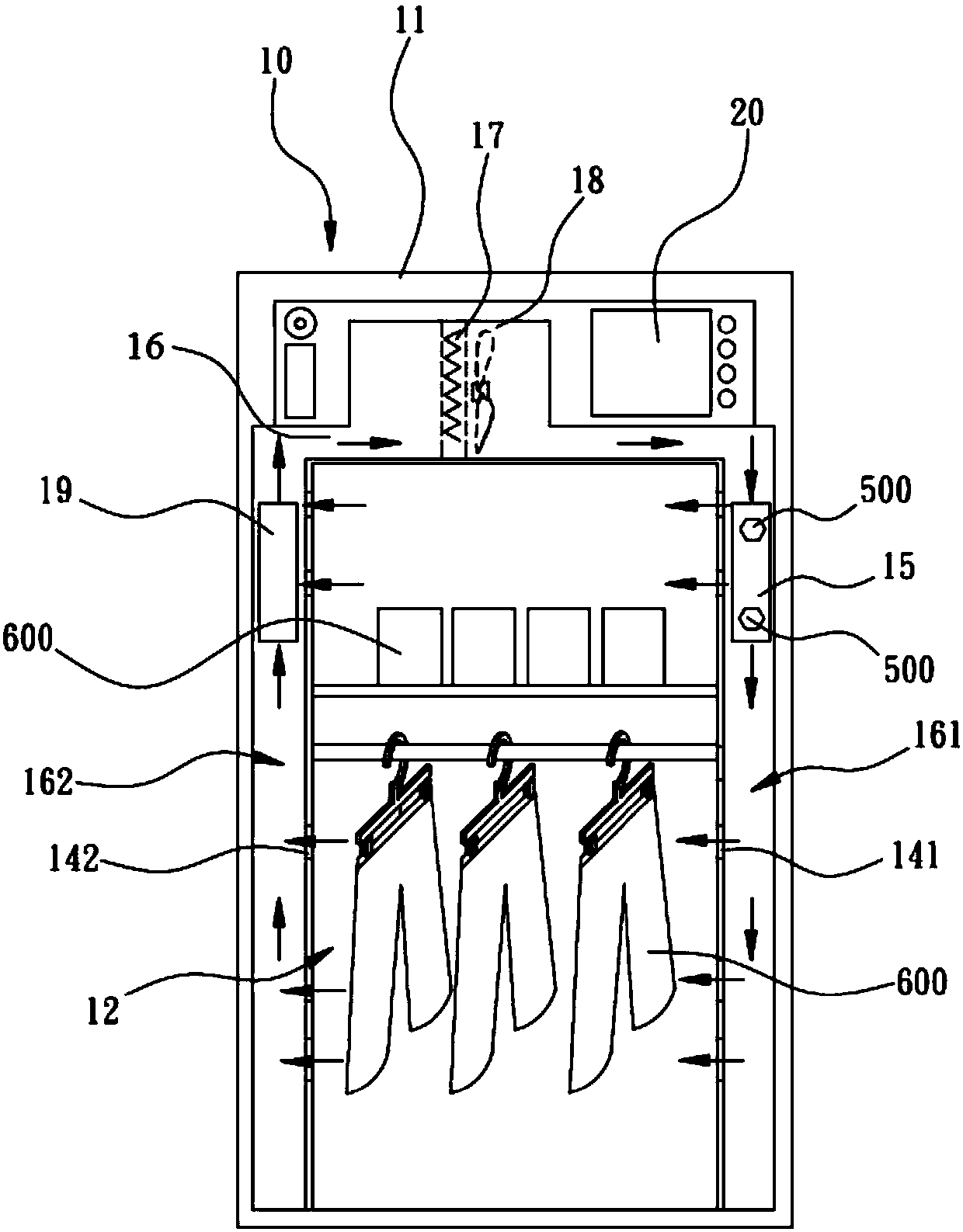

[0052] The present invention provides a preparation method and equipment of textiles with far-infrared radiation energy and the prepared textiles, please refer to figure 1 , which is a flow chart of a preparation method of an embodiment of the invention, comprising the following steps:

[0053] Step (a), preparing a powerful ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com