High-CTI (comparative tracking index) halogen-free flame retardant resin composition for copper-clad laminate

A technology of flame-retardant resin and copper-clad substrate, which is applied in the field of high CTI value halogen-free flame-retardant resin composition, can solve the problem that ATH is added less and the flame retardancy cannot meet the requirements, and the heat resistance of FR4 board is not good. Heat resistance decline and other problems, to achieve the effect of high heat resistance of the system, high CTI value, and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

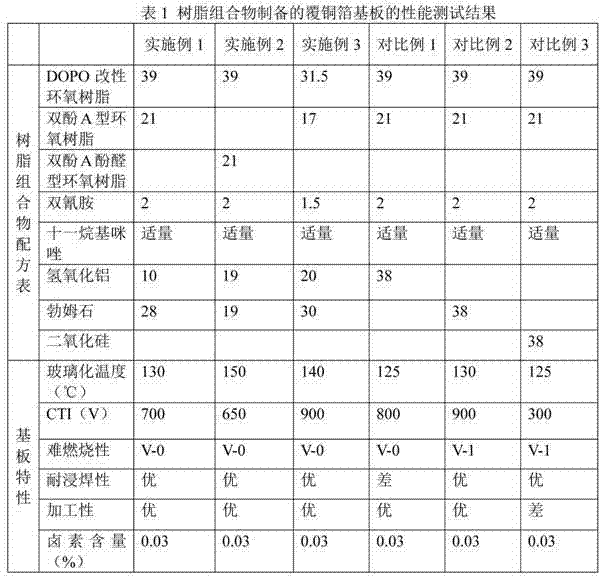

[0040] A high CTI value halogen-free flame-retardant resin composition, containing the following components in parts by weight: 39 parts of DOPO modified epoxy resin, 21 parts of bisphenol A epoxy resin, 2 parts of dicyandiamide, undecyl 0.3 parts of imidazole, 10 parts of aluminum hydroxide, 28 parts of boehmite.

Embodiment 2

[0042] A high CTI value halogen-free flame-retardant resin composition, containing the following components in parts by weight: 39 parts of DOPO modified epoxy resin, 21 parts of bisphenol A novolac epoxy resin, 2 parts of dicyandiamide, undecane 0.2 parts of imidazole, 19 parts of aluminum hydroxide, and 19 parts of boehmite.

Embodiment 3

[0044] A high CTI value halogen-free flame-retardant resin composition, containing the following components in parts by weight: 31.5 parts of DOPO modified epoxy resin, 17 parts of bisphenol A novolac epoxy resin, 1.5 parts of dicyandiamide, undecane 0.5 parts of imidazole, 20 parts of aluminum hydroxide, and 30 parts of boehmite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com