Epoxy resin composition and application thereof

A technology of epoxy resin and composition, which is applied in the field of laminates, can solve the problems of heat resistance, moisture resistance and alkali resistance of the board, unsatisfactory product adhesion, and decreased flame retardancy of the board, etc., to achieve good resistance. Burning effect, improve designability, improve the effect of poor heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

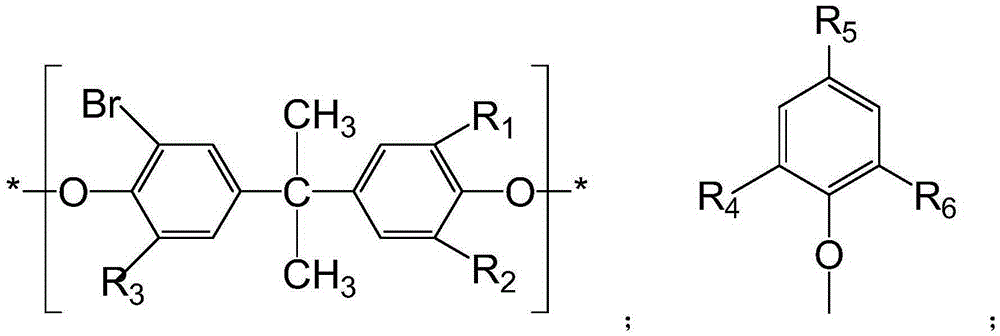

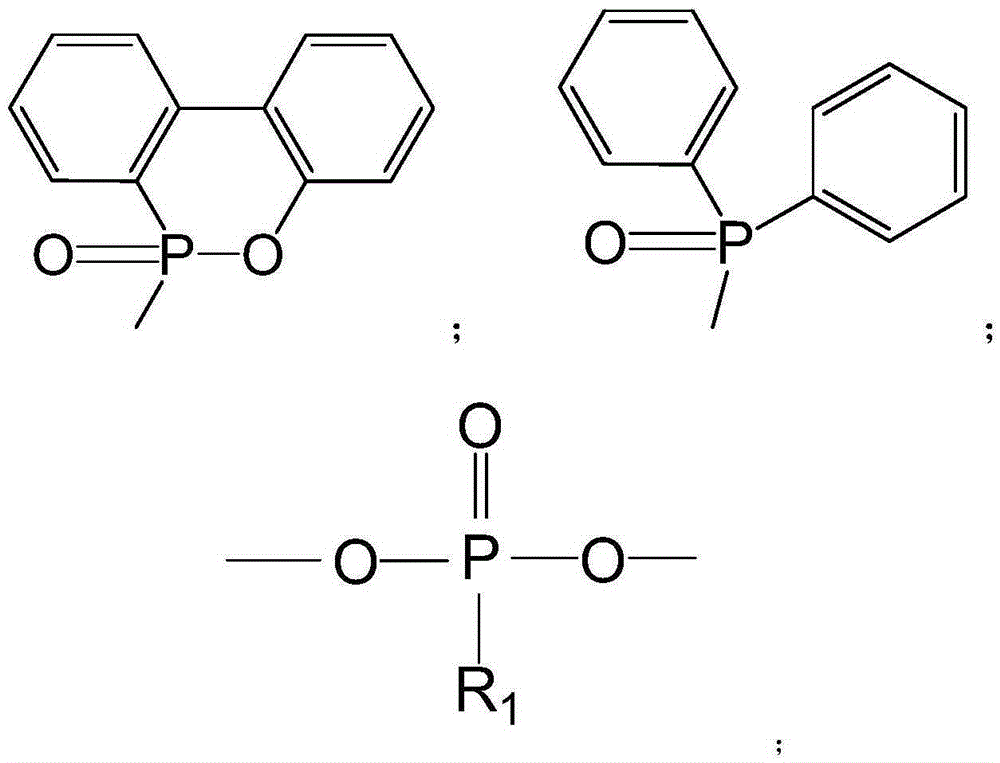

[0056] Preparation Example 1 Synthesis of Bisphenol A Type Phosphorus and Bromine-Containing Epoxy Resins (1)

[0057] By weight, 100 parts of EPIKOTE828EL and 10.8 parts of DOPO-HQ were mixed together and heated, and when heated to 130°C, 0.05-0.15 part of ethyl triphenylphosphine bromide was added, and the heating was continued at 135-150° C. React for 1 to 3 hours, cool down to below 135°C, add 50 parts of TBBPA and mix evenly, add 0.05 to 0.15 parts of ethyltriphenylphosphine bromide when heated to 130°C, and react at 135-150°C for 2 to 4 hours, Then, the temperature is lowered to below 130° C., and methyl ethyl ketone (MEK) is added to dissolve it into a MEK solution with a solid content of 80% to obtain a bisphenol A type epoxy resin containing phosphorus and bromine. The bromine content of the resin is 18.0% and the phosphorus content is 0.63%.

[0058] Preparation example 2 Synthesis of bisphenol A type phosphorus and bromine-containing epoxy resin (two)

[0059] ...

preparation example 3

[0060] Synthesis of preparation example 3 phenol formaldehyde type phosphorus and bromine-containing epoxy resin (1)

[0061] By weight, 100 parts of PNE177 and 33.5 parts of DOPO were mixed together and heated, and when heated to 130 °C, 0.05-0.15 parts of ethyl triphenylphosphine bromide was added, and the heating was continued, and the reaction was carried out at 145-160 ° C for 2 ~4 hours, cool down to below 135°C, add 28 parts of TBBPA and mix evenly, add 0.05-0.15 parts of ethyltriphenylphosphine bromide when heated to 130°C, react at 135-150°C for 2-4 hours, then cool down When the temperature is below 130° C., butanone (MEK) is added to dissolve it into a MEK solution with a solid content of 70% to obtain a phenol formaldehyde type epoxy resin containing phosphorus and bromine. The bromine content in the resin is 10% and the phosphorus content is 3.0%.

preparation example 4

[0062] Synthesis of preparation example 4 phenol formaldehyde type epoxy resin containing phosphorus and bromine (two)

[0063] By weight, 100 parts of PNE177 and 30 parts of DOPO were mixed together and heated, and when heated to 130 °C, 0.05-0.15 parts of ethyltriphenylphosphine bromide was added, and the heating was continued, and the reaction was carried out at 145-160 °C for 2 ~4 hours, cool down to below 135°C, add 15 parts of TBBPA and mix well, add 0.05-0.15 parts of ethyl triphenylphosphine bromide when heated to 130°C, react at 135-150°C for 2-4 hours, then cool down When the temperature is below 130° C., butanone (MEK) is added to dissolve it into a MEK solution with a solid content of 70% to obtain a phenol formaldehyde type epoxy resin containing phosphorus and bromine. The bromine content in the resin is 6.0% and the phosphorus content is 3.0%.

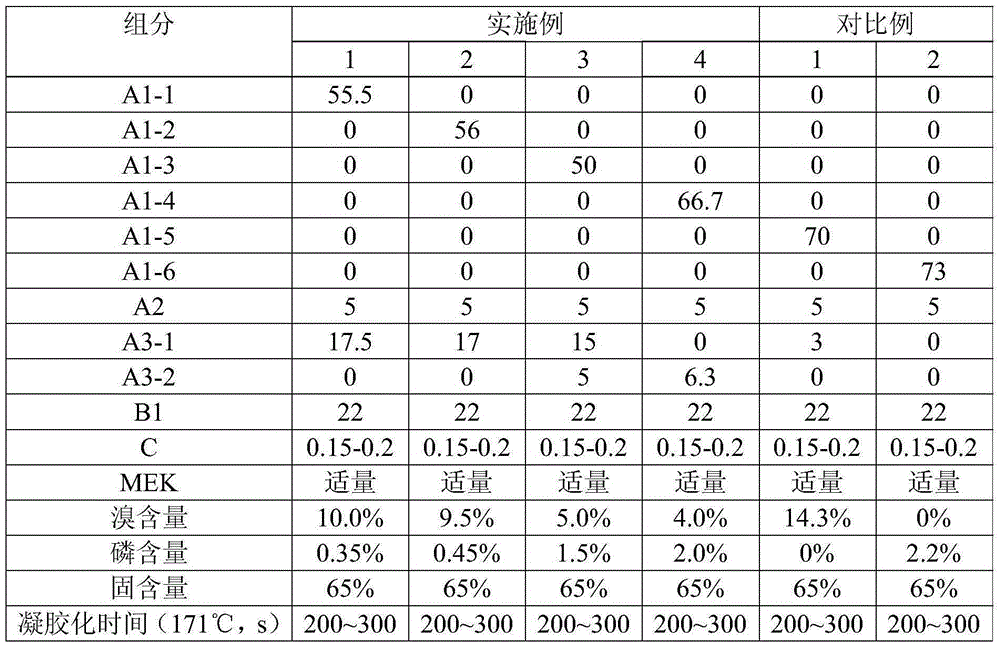

[0064] Preparation method of copper-clad laminate of embodiment and comparative example

[0065] (1) Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com