Flame-retardant non-reinforced nylon with high glow wire and high CTI (comparative tracking index) value, and preparation method thereof

A high glow wire, nylon technology, applied in high CTI value flame retardant non-reinforced nylon and its preparation, in the field of high glow wire, to achieve high CTI characteristics, high glow wire temperature, and good technical applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

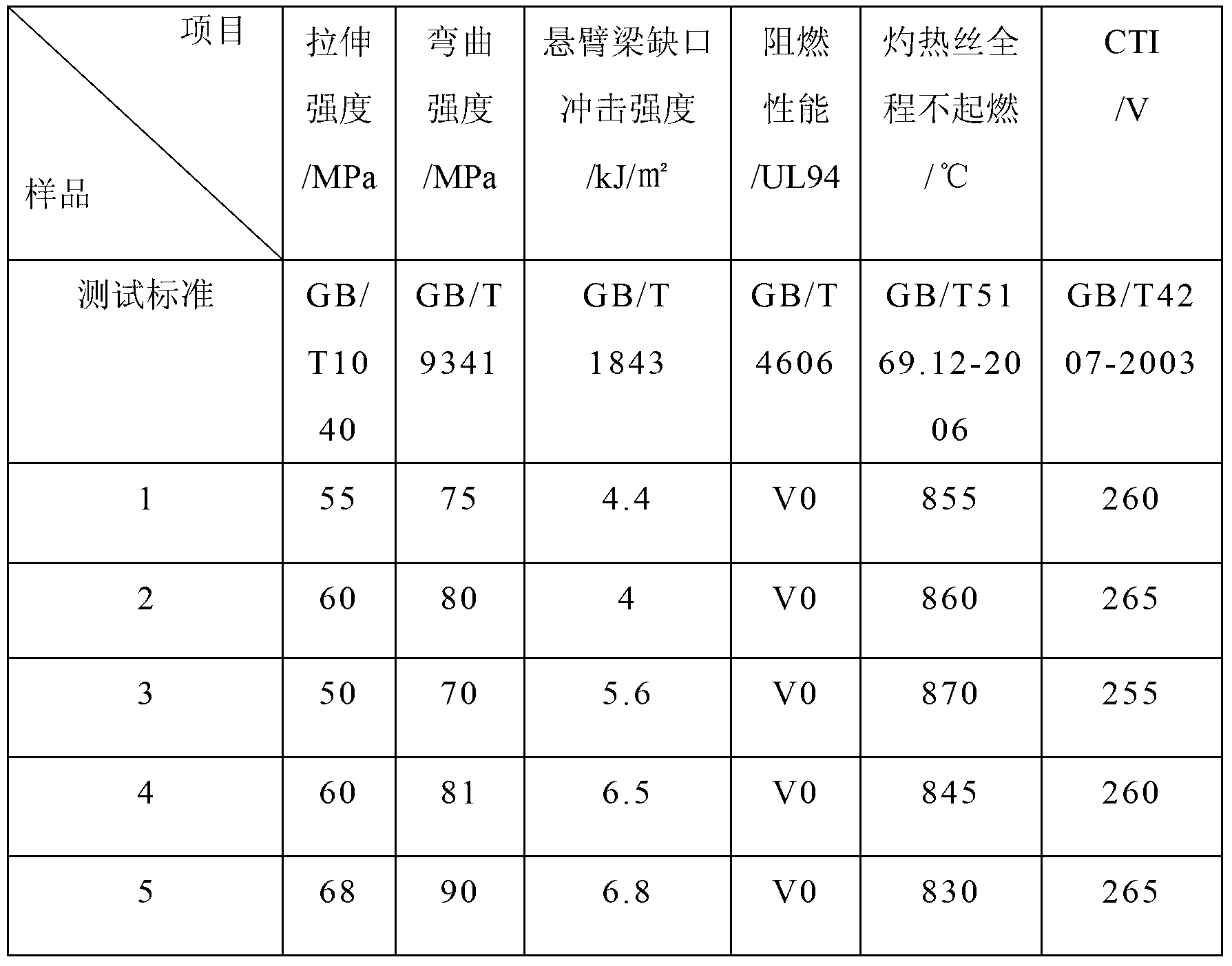

Examples

Embodiment 1

[0029] A high glow wire, high CTI value flame retardant non-reinforced nylon, its formula composition is shown in Table 1:

[0030] Table 1 Nylon formulation

[0031] raw material

Embodiment 2

[0033] A high glow wire, high CTI value flame retardant non-reinforced nylon, its formula composition is shown in Table 2:

[0034] Table 2 nylon formula

[0035] raw material

[0036] brominated polystyrene

Embodiment 3

[0038] A high glow wire, high CTI value flame retardant non-reinforced nylon, its formula composition is shown in Table 3:

[0039] Table 3 Nylon formulation

[0040] raw material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com