Halogen-free and flame-retardant nylon master batch with high CTI (Comparative Tracking Index) value and preparation method thereof

A flame-retardant nylon masterbatch technology, applied in the field of halogen-free flame-retardant nylon masterbatch and preparation, can solve the problems of appearance, processing performance and physical and mechanical performance deterioration, difficult to accurately control the addition ratio, hidden dangers of labor protection for operators, etc., to achieve Easy industrial production, good mechanical properties, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

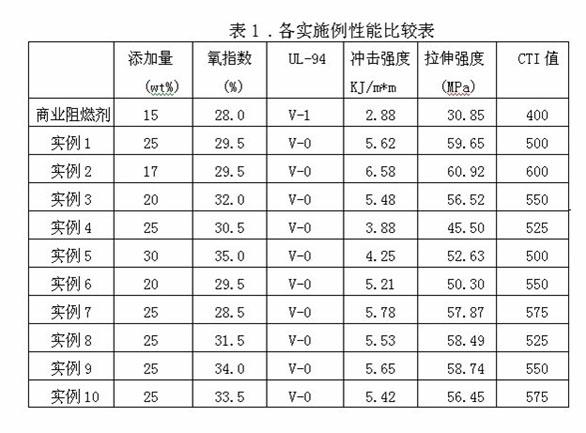

Examples

Embodiment 1

[0017] 400g melamine polyphosphate, 200gFR-1 Fenghong flame retardant modified clay, 350g nylon 6, 4g antioxidant 1076, 30g PE maleic anhydride graft, 7g coupling agent KH-550, 9g calcium stearate Add it into a kneader, stir and mix evenly, dry it under vacuum at 60°C after starting, and then melt, extrude, and pelletize through a twin-screw extruder to obtain 1000g of flame-retardant nylon masterbatch finished product.

Embodiment 2

[0019] Add 450g red phosphorus, 80g zinc borate, 400g nylon 66, 20g antioxidant 1010, 20g POE maleic anhydride graft, 5g coupling agent KH-570, 25g zinc stearate into the kneader, stir and mix evenly, After starting the material, dry it under vacuum at 80°C, and then melt, extrude and granulate through a twin-screw extruder to obtain 1000g of flame-retardant nylon masterbatch finished product.

Embodiment 3

[0021] Add 520g melamine, 150g zinc oxide, 250g nylon 610, 5g antioxidant 626, 10g POE maleic anhydride graft, 20g PE maleic anhydride graft, 17g coupling agent NSZ-20, 28g polyethylene wax and knead In the machine, stir and mix evenly, dry at 90°C in vacuum after starting the material, and then melt, extrude, and granulate through a twin-screw extruder to obtain 1000g of flame-retardant nylon masterbatch finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com