Halogen-free flame retardant epoxy resin composition and copper clad plate prepared from same

A technology of epoxy resin and composition, used in circuit substrate materials, layered products, metal layered products, etc., can solve the problems of heat evaporation of moisture pollutants, low tracking index, breakdown short circuit/open circuit, etc. , to achieve the effect of high CTI and flame retardancy, avoiding dry flowers or exposed cloth lines, and high leakage and tracking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

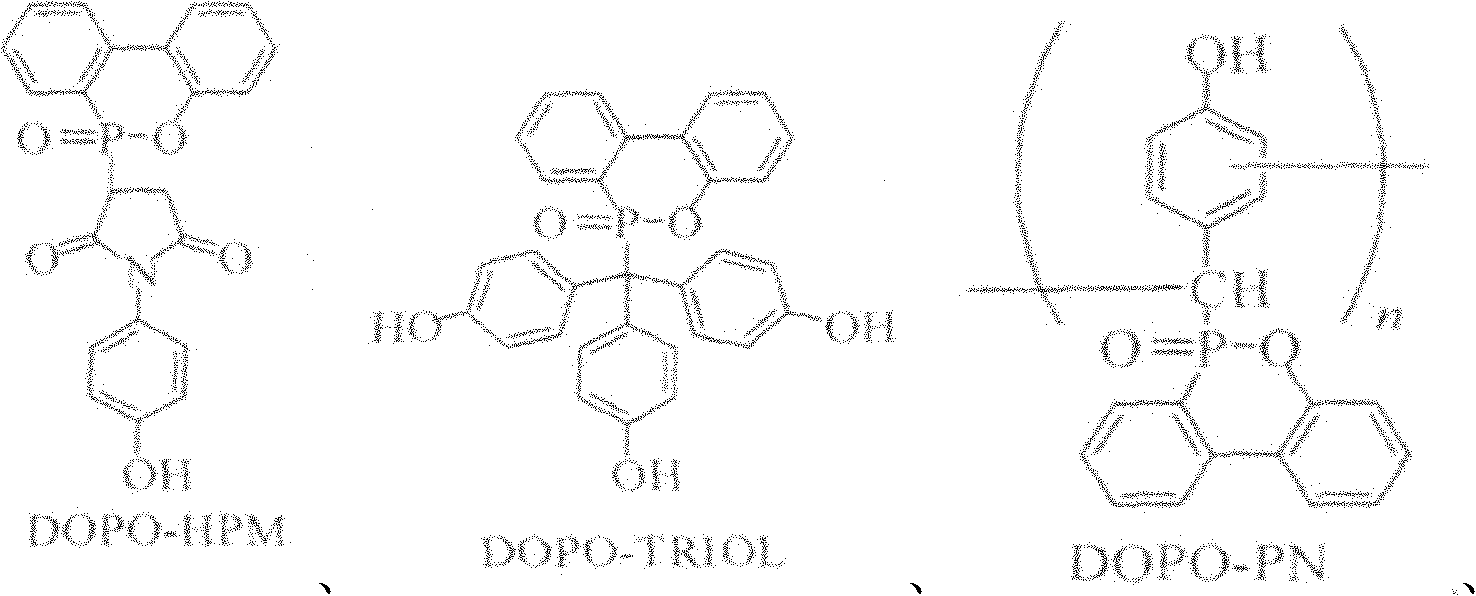

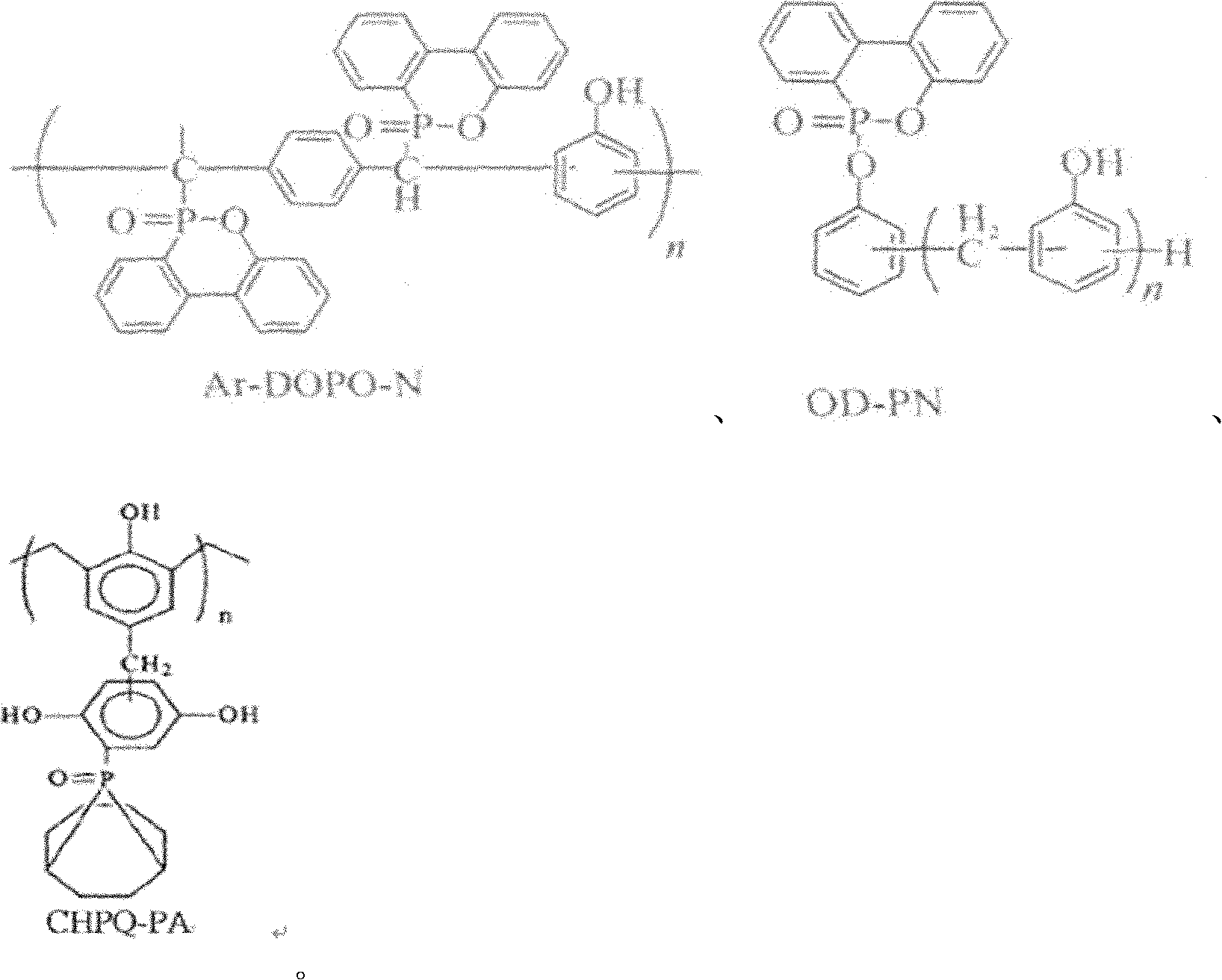

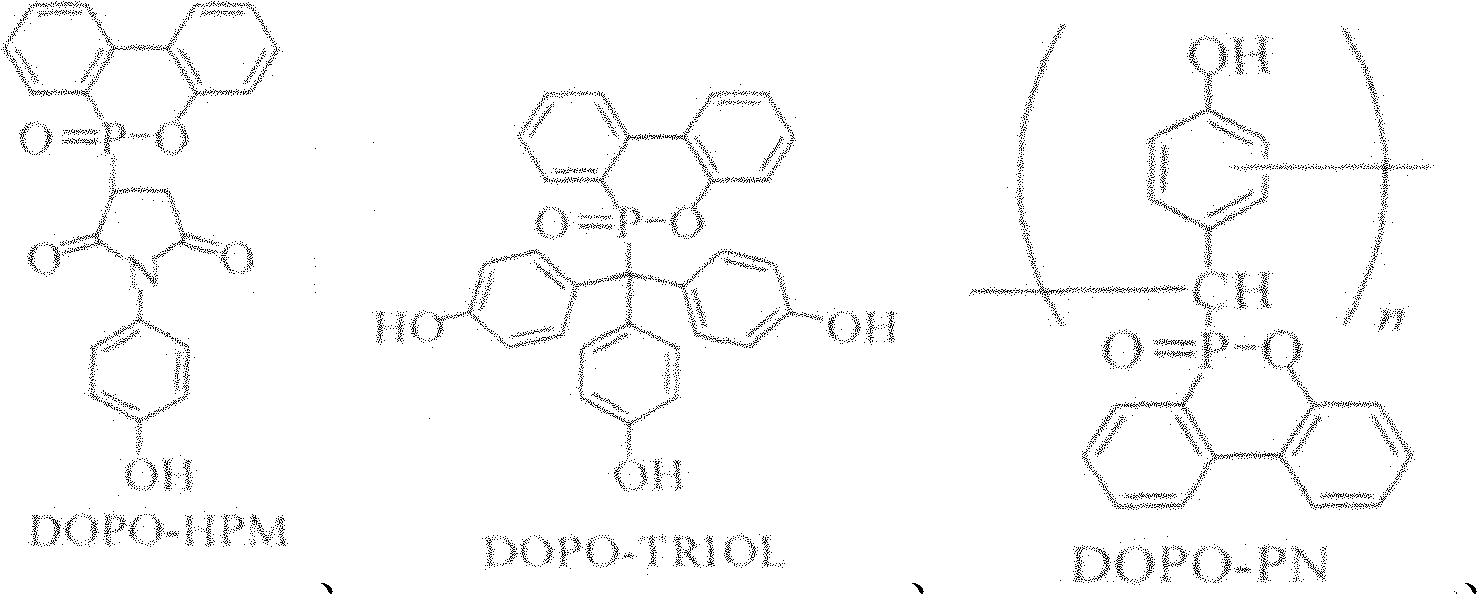

Method used

Image

Examples

Embodiment 1

[0038] Preparation of Halogen-free Flame Retardant Epoxy Resin Composition Glue

[0039] Weigh 44 parts of bisphenol A epoxy resin (Epikote 1002), 30 parts of carboxyl-terminated nitrile rubber (Nipol1072CG), 26 parts of phosphorus-containing phenolic resin (XZ92741), 20 parts of nitrogen-based flame retardant (melapurMC15), hydrogen 30 parts of aluminum (average particle size is 1 to 5um, purity above 99%), 0.7 part of dicyandiamide and 0.1 part of 2-ethyl-4-methylimidazole, dissolve the above components with dimethylformamide solvent to form a gel Liquid, the solid content of the glue is adjusted to 50%, and the glue of the halogen-free flame-retardant epoxy resin composition is made.

[0040] Preparation of copper clad laminate

[0041] Stack 8 sheets of FR-4 prepregs or bonding sheets with a size of 300mm×300mm neatly, and apply the prepared glue on the laminate through the coating machine on the upper and lower sides, with a thickness of 50 μm. Then put it into an oven ...

Embodiment 2

[0043] Repeat the preparation of Example 1, the difference is that in the glue system of the halogen-free flame-retardant epoxy resin composition, 35 parts of bisphenol A type epoxy resin (Epikote 1002), 30 parts of carboxyl-terminated nitrile rubber (Nipol1072CG), 13 parts of phosphorus-containing epoxy resin (YEP-250), 22 parts of phosphorus-containing phenolic resin (XZ92741), 10 parts of nitrogen-based flame retardant (melapur MC15), aluminum hydroxide (average particle size 1 to 5 μm, purity 99% 30 parts of the above), 0.45 parts of dicyandiamide and 0.1 part of 2-ethyl-4-methylimidazole, and the preparation of other steps is the same as in Example 1.

Embodiment 3

[0045] Repeat the preparation of Example 1, the difference is that in the glue system of the halogen-free flame-retardant epoxy resin composition, 19 parts of bisphenol A type NOVOLAC epoxy resin (EPR627, manufactured by Hexion Company) and bisphenol A type epoxy resin are used. (Epikote 1002) 25 parts, carboxyl-terminated nitrile rubber (Nipol 1072CG) 30 parts, phosphorus-containing phenolic resin (XZ92741) 26 parts, nitrogen-based flame retardant (melapur MC15) 10 parts, aluminum hydroxide (average particle size 1 to 5 μm, purity above 99%) 30 parts, 0.75 parts of dicyandiamide and 0.1 part of 2-ethyl-4-methylimidazole, and the preparation of other steps is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com