Halogen-free flame-retardant epoxy resin composition, and adhesive film and copper-clad plate prepared from same

A technology of epoxy resin and composition, applied in the direction of epoxy resin glue, synthetic resin layered product, aldehyde/ketone condensation polymer adhesive, etc. , breakdown short circuit/open circuit and other problems, to achieve the effect of high CTI and flame retardancy, avoiding dry flowers or exposed cloth lines, and high leakage and tracking characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

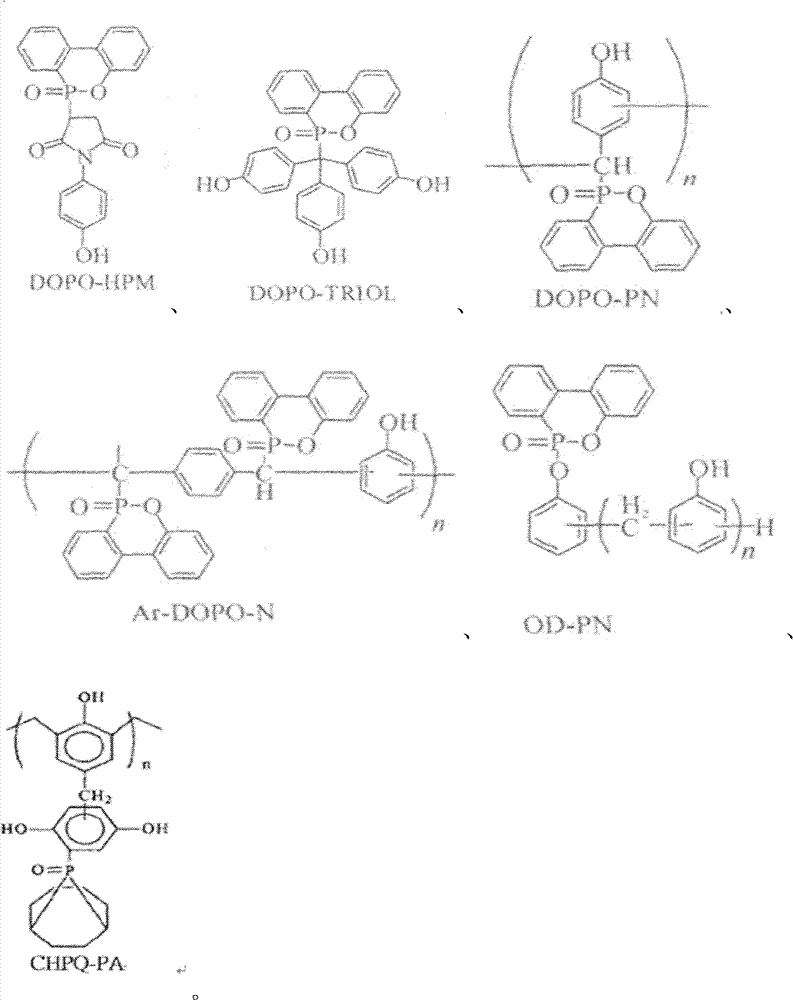

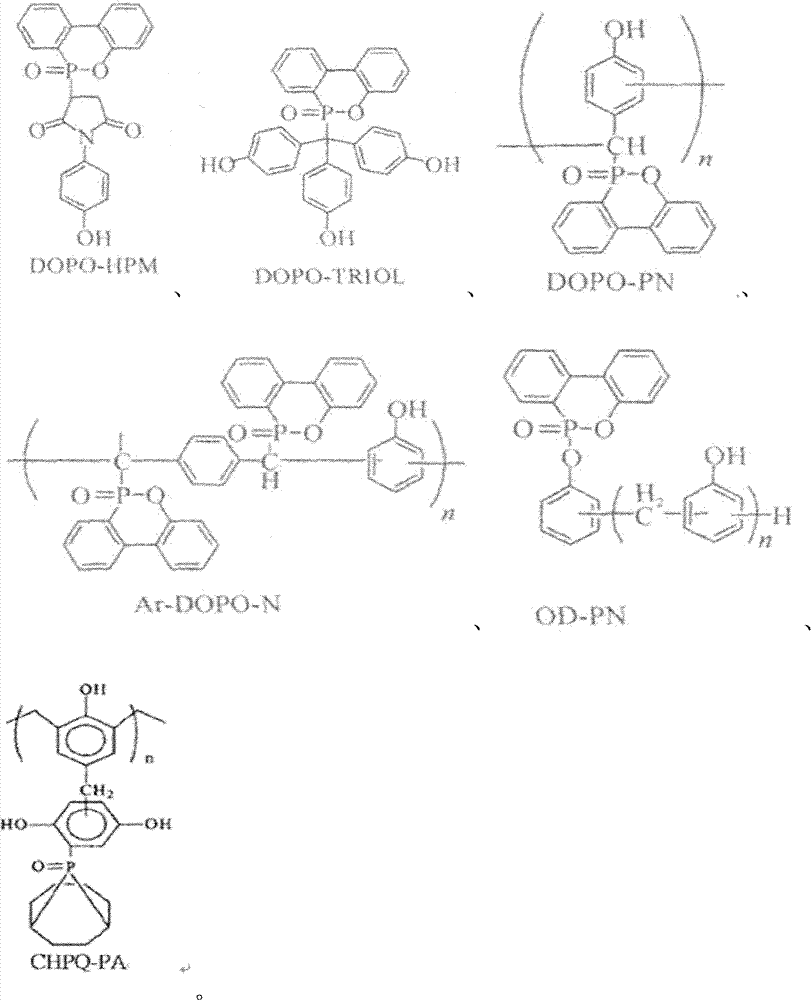

Method used

Image

Examples

Embodiment 1

[0038] Preparation of Glue and Film of Halogen-free Flame Retardant Epoxy Resin Composition

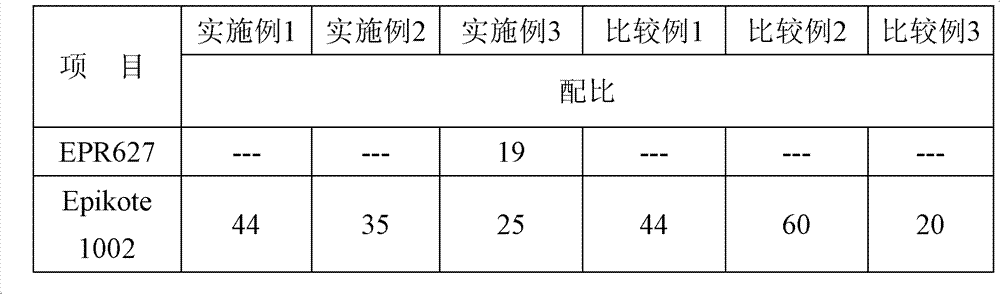

[0039] Weigh 44 parts by weight of bisphenol A epoxy resin (Epikote 1002), 30 parts by weight of carboxyl-terminated nitrile rubber (Nipol 1072CG), 26 parts by weight of phosphorus-containing phenolic resin (XZ92741), nitrogen-based flame retardant (melapur MC15) 20 parts by weight, 30 parts by weight of aluminum hydroxide (average particle diameter is 1 to 5um, purity more than 99%), 0.7 parts by weight of dicyandiamide and 0.1 parts by weight of 2-ethyl-4-methylimidazole, with dimethyl The formamide solvent dissolves the above components to form a glue solution, and the solid content of the glue solution is adjusted to 50% to prepare a halogen-free flame-retardant epoxy resin composition glue solution. Coat the glue solution on the PET release film through a coating machine, the thickness of the glue coating is 50 μm, and then heat it in an oven at 155 ° C for 5 minutes. The glue so...

Embodiment 2

[0043] Repeat the preparation of Example 1, the difference is that in the glue system of the halogen-free flame-retardant epoxy resin composition, 35 parts by weight of bisphenol A type epoxy resin (Epikote 1002) and 30 parts by weight of carboxyl-terminated nitrile rubber (Nipol1072CG) are used Parts, 13 parts by weight of phosphorus-containing epoxy resin (YEP-250), 22 parts by weight of phosphorus-containing phenolic resin (XZ92741), 10 parts by weight of nitrogen-based flame retardant (melapur MC15), aluminum hydroxide (average particle diameter is 1 to 5 μm, purity more than 99%) 30 parts by weight, 0.45 parts by weight of dicyandiamide and 0.1 part by weight of 2-ethyl-4-methylimidazole, and the preparation of other steps is the same as in Example 1.

Embodiment 3

[0045] Repeat the preparation of Example 1, the difference is that in the glue system of the halogen-free flame-retardant epoxy resin composition, adopt bisphenol A type NOVOLAC epoxy resin (EPR627, Hexion company manufactures) 19 parts by weight, bisphenol A type epoxy resin 25 parts by weight of resin (Epikote 1002), 30 parts by weight of carboxyl-terminated nitrile rubber (Nipol1072CG), 26 parts by weight of phosphorus-containing phenolic resin (XZ92741), 10 parts by weight of nitrogen-based flame retardant (melapur MC15), aluminum hydroxide (average 30 parts by weight of particle size (1 to 5 μm, purity above 99%), 0.75 parts by weight of dicyandiamide and 0.1 part by weight of 2-ethyl-4-methylimidazole, and the preparation of other steps is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com