High cti halogen-free epoxy resin composition for copper clad laminate and its application

A technology of halogen-free epoxy resin and halogen epoxy resin, applied in the direction of epoxy resin coating, application, synthetic resin layered products, etc., can solve the problems of poor heat resistance and poor heat resistance of FR4 boards, etc. achieve high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

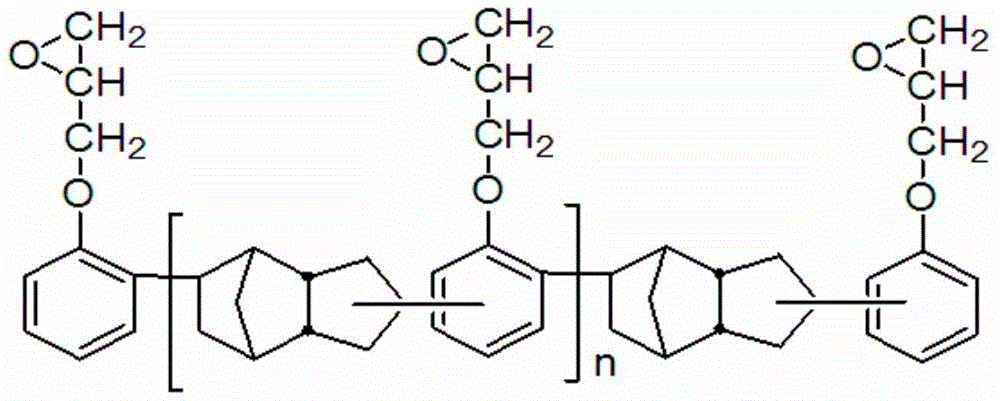

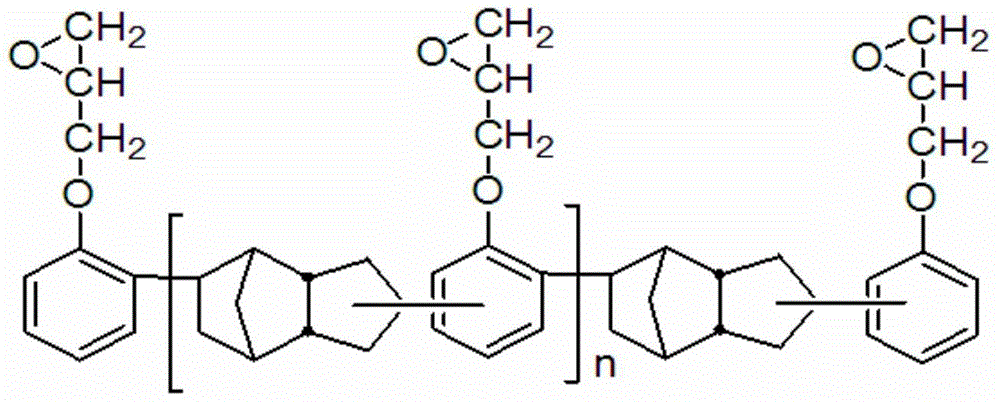

[0026] The main body of this resin is straight-chain phosphorus-containing epoxy resin, which has high CTI value, flame retardancy, good toughness and adhesion. The linear epoxy resin is selected from BPA type, BPF type or bisphenol S type linear epoxy resin; the reactive phosphorus compound is selected from one or a mixture of DOPO-HQ and DOPO-NQ. The synthesis method of the epoxy resin is: 1). Weigh each raw material according to the formula, and the formula contains the following raw materials in mass percentage: 55% to 75% of epoxy resin; 25% to 45% of reactive phosphorus-containing compound; wherein, the The epoxy resin is a linear epoxy resin; 2). Preparation of halogen-free phosphorus-containing epoxy resin: add the linear epoxy resin and the reactive phosphorus-containing compound in the reaction tank, heat up and dissolve, and dissolve at 110 ~ Add the catalyst at 130°C, then raise the temperature to 170-190°C, react for 2-4 hours, then lower the temperature and add a...

Embodiment 1

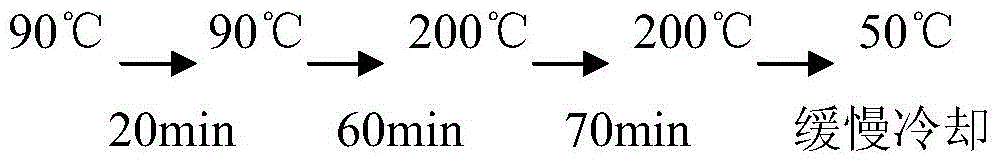

[0049] The composition (A1+7200HHH) of the present invention is used as the main resin, combined with curing agent DDM type benzoxazine and phenolic resin GERH833K65, and aluminum hydroxide is used as the filler. Use methyl ether (PM) or propylene glycol methyl ether acetate to adjust the varnish composition with a solid content of 55%, impregnate 7628 glass fiber cloth in the above varnish resin solution, and then dry it for several minutes in an impregnation machine at a temperature of 170-180°C. Control the drying time so that the melt viscosity of the dried prepreg is between 800 and 1800Pa.s, and finally put 8 pieces of film layer by layer between two pieces of 35μm thick copper foil, at 25Kg / cm 2 Pressure and temperature are controlled as follows:

[0050]

[0051] After hot pressing, a 1.6mm copper foil substrate can be obtained. The composition has a CTI of over 500V, a Tg of over 150°C, good heat resistance, and a V0 level of flame retardancy. The functions are d...

Embodiment 2

[0053] Repeating Example 1, changing the ratio of components A1 and 7200HHH, the CTI of the obtained composition is above 500V, the Tg is above 150°C, the heat resistance is good, and the flame retardancy reaches V0 level. The functions are detailed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com