A kind of chlorine-free bromine-free high cti resin composition and application

A resin composition and epoxy resin technology, applied in the field of copper clad laminates, can solve the problems of low decomposition temperature, large particle size of barium sulfate, low surface tension, etc., and achieve the effects of high thermal decomposition temperature, good stability and high CTI

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] raw material:

[0032] (A) epoxy resin, the epoxy equivalent of epoxy resin is 170~950g / eq. Epoxy resin can be selected from following four kinds of epoxy resins of A-1, A-2, A-3 and A-4,

[0033] (A-1) Epoxy resin GESR901 of Hongchang Electronic Materials Co., Ltd., epoxy equivalent 459g / eq;

[0034] (A-2) Japan DIC chemical medicine HP-7200H dicyclopentadiene phenol epoxy resin, epoxy equivalent 135g / eq;

[0035] (A-3) bisphenol A novolac epoxy resin BNE200 of China Taiwan Changchun Artificial Resin Factory Co., Ltd., epoxy equivalent 202g / eq;

[0036](A-4) DOPO phenol novolak epoxy resin TX-1328 of Nippon Steel Sumikin Chemical Co., Ltd., epoxy equivalent 320g / eq;

[0037] (B) Phosphorus-containing phenolic resin XZ83028 of Lanke Chemical (Zhangjiagang) Co., Ltd.;

[0038] (C) amine curing agent is selected from

[0039] (C-1) Dicyandiamide, purchased from Ningxia Jiafeng Chemical Co., Ltd.;

[0040] (C-2) DDS, purchased from Hubei Yuancheng Saichuang Technolog...

Embodiment 1~5 and comparative example 1~5

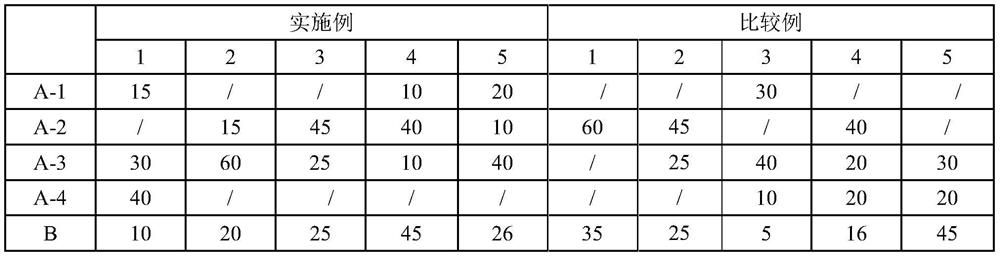

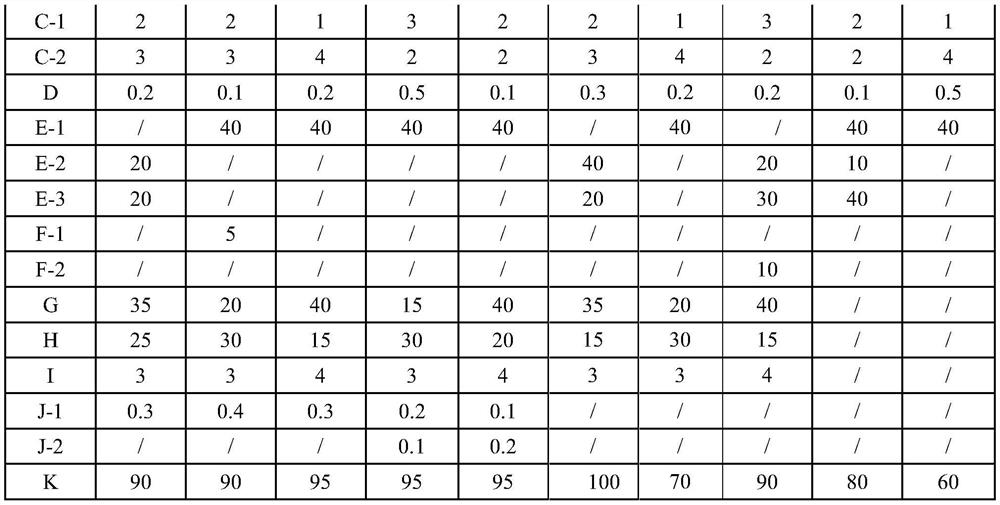

[0060] The raw materials A-1, A-2, A-3, A-4, B, C-1, C-2, D, E-1, E-2, E-3, F-1 in the above embodiment , F-2, G, H, I, J-1, J-2, and K prepared resin compositions according to the formula in Table 1, and prepared copper clad laminates from the resin compositions.

[0061] Table 1 Recipe

[0062]

[0063]

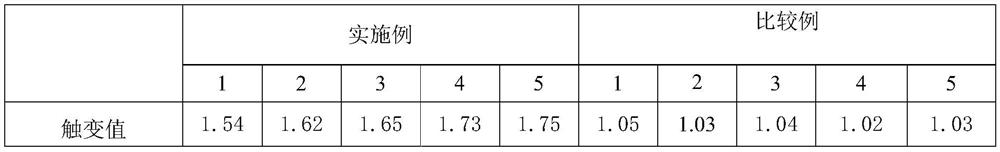

[0064] Examples 1-5 and Comparative Examples 1-5 were prepared according to the above-mentioned method for preparing copper-clad laminates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com