Flame-retardant enhanced PBT material and preparation method thereof

A technology of PBT resin and brominated flame retardant, which is applied in the field of flame-retardant reinforced PBT materials and its preparation, can solve the problems of halogen-free flame-retardant PBT material technology and cost limitations, poor mechanical properties, and large additions, and achieve The effects of high tracking index, good mechanical properties and high ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

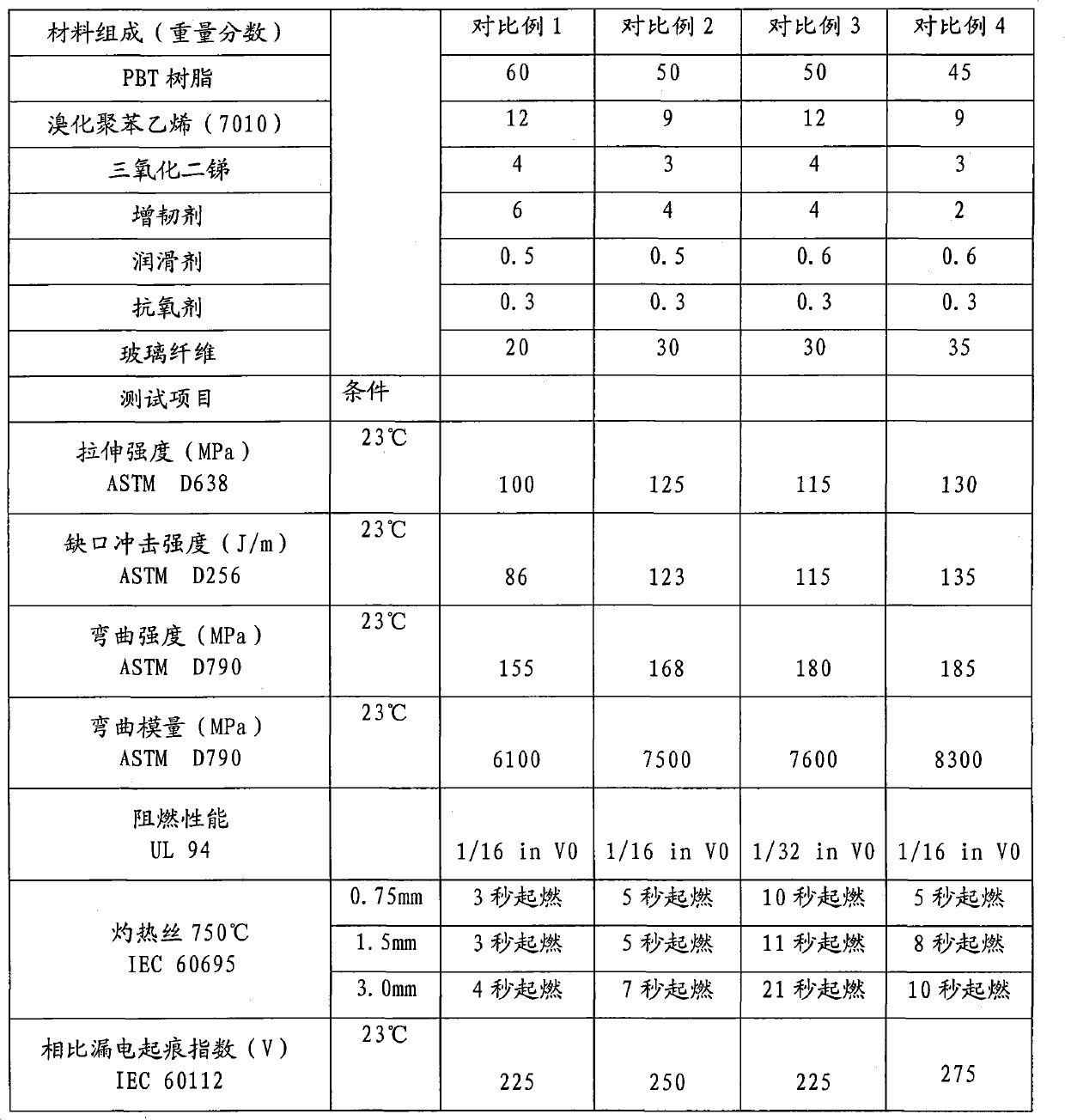

Examples

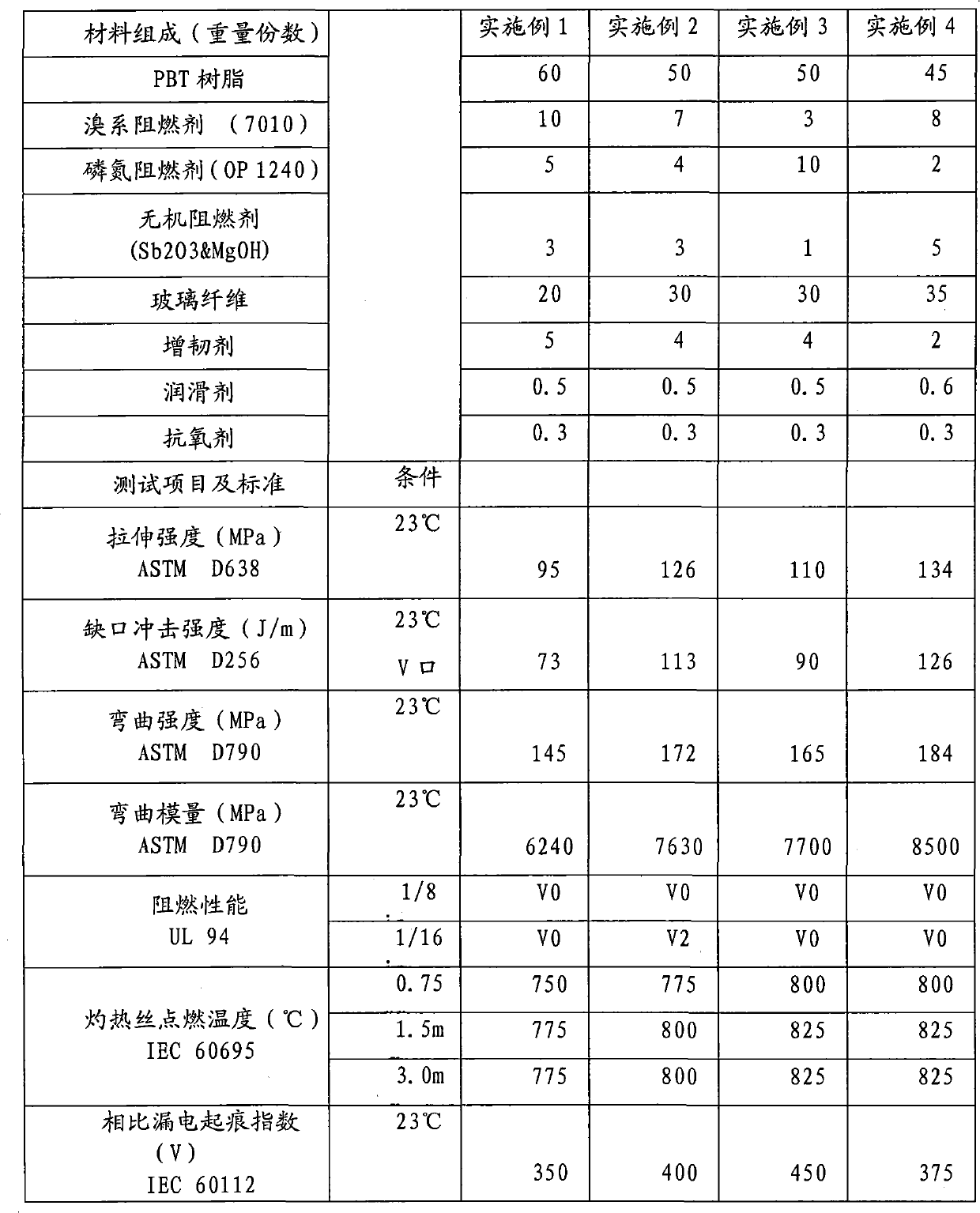

Embodiment 1

[0033] The weight percentage of PBT 59.0%, PBT 60%, brominated flame retardant 10%, phosphorus nitrogen flame retardant 5%, inorganic flame retardant 3%, toughening agent 5%, lubricant 0.3%, antioxidant 0.3% Stir in a mixing barrel for 5 minutes, and then melt, extrude and granulate through a twin-screw extruder, and add 20% of long fibers from the middle section of the extruder at the same time. The processing technology is as follows: twin-screw extruder, the first zone is 200°C, the second zone is 220°C, the third zone is 220°C, the fourth zone is 220°C, the fifth zone is 190°C, the sixth zone is 190°C, the seventh zone is 210°C, and the eighth zone is 230°C; The number of revolutions of the screw is controlled at 420 to 480 revolutions per minute.

Embodiment 2

[0035] Put 50% of PBT, 7% of brominated flame retardant, 4% of phosphorus nitrogen flame retardant, 3% of inorganic flame retardant, 4% of toughening agent, 0.5% of lubricant, and 0.3% of antioxidant in the mixing tank Stir for 5 minutes, then melt, extrude and granulate through a twin-screw extruder, and at the same time add 30.0% of long fibers from the middle section of the extruder. The processing technology is as follows: twin-screw extruder, the first zone is 200°C, the second zone is 230°C, the third zone is 230°C, the fourth zone is 230°C, the fifth zone is 190°C, the sixth zone is 190°C, the seventh zone is 210°C, and the eighth zone is 230°C; The number of revolutions of the screw is controlled at 420 to 480 revolutions per minute.

Embodiment 3

[0037] Put 50% by weight of PBT, 3% of brominated flame retardant, 10% of phosphorus nitrogen flame retardant, 1% of inorganic flame retardant, 4% of toughening agent, 0.5% of lubricant, and 0.3% of antioxidant in the mixing tank Stir for 5 minutes, then melt, extrude and granulate through a twin-screw extruder, and at the same time add 30.0% of long fibers from the middle section of the extruder. The processing technology is as follows: Twin-screw extruder in the first zone 190°C, in the second zone 210°C, in the third zone 210°C, in the fourth zone 210°C, in the fifth zone 190°C, in the sixth zone 190°C, in the seventh zone 210°C, in the eighth zone 230°C; The number of revolutions of the screw is controlled at 420 to 480 revolutions per minute.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com