Halogen-free flame retarding strengthened PA66 material and preparation method thereof

A technology of compatible toughening agent and weight ratio, which is applied in the field of halogen-free flame-retardant reinforced PA66 materials for circuit breaker shells and its preparation, can solve the problems of non-compliance with halogen-based flame retardants, poor flame-retardant effect, and CTI value Decrease and other issues, to achieve the effect of high cost performance, increase CTI value, and high CTI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

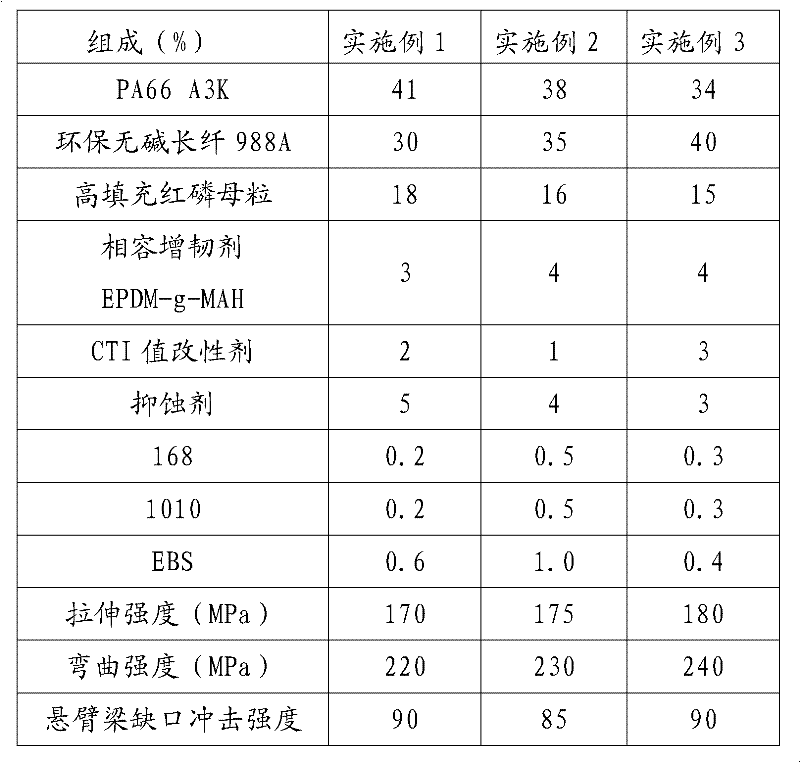

Embodiment 1

[0031] Weigh raw materials according to weight percentage, PA66 resin 41%, highly filled red phosphorus masterbatch 18%, CTI modifier 2%, corrosion inhibitor 5%, compatible toughener 3%, antioxidant 0.4%, lubrication Mix 0.6% of the agent evenly to obtain the mixed raw materials; pour the above mixed raw materials into the barrel of the twin-screw machine, adjust the screw speed and the main feeding speed, add 30% of the alkali-free long glass fiber, and extrude and granulate under suitable process conditions. The halogen-free flame-retardant reinforced PA66 pellets were obtained. The process conditions are: the temperature of the feeding section in the first zone is 260-290°C, the temperature of the compression section in the second zone is 260-280°C, the temperature in the metering section of the third zone is 250-280°C, the temperature of the head in the fourth zone is 270°C, and the screw speed is 550RPM.

[0032] Among them, the mixed raw materials are added at the main f...

Embodiment 2

[0035] Weigh raw materials according to weight percentage, PA66 resin 38%, highly filled red phosphorus masterbatch 16%, CTI modifier 1%, corrosion inhibitor 4%, compatible toughener 4%, antioxidant 1.0%, lubrication Mix 1.0% of the agent evenly to obtain the mixed raw materials; pour the above mixed raw materials into the barrel of the twin-screw machine, adjust the screw speed and the main feeding speed, add 35% of the alkali-free long glass fiber, and extrude and granulate under suitable process conditions. The halogen-free flame-retardant reinforced PA66 pellets were obtained. The process conditions are: the temperature of the feeding section in the first zone is 260-290°C, the temperature of the compression section in the second zone is 260-280°C, the temperature in the metering section of the third zone is 250-280°C, the temperature of the head in the fourth zone is 270°C, and the screw speed is 550RPM.

[0036] Among them, the mixed raw materials are added at the main f...

Embodiment 3

[0039] Weigh raw materials according to weight percentage, PA66 resin 34%, highly filled red phosphorus masterbatch 15%, CTI modifier 3%, corrosion inhibitor 3%, compatible toughener 4%, antioxidant 0.6%, lubrication Mix 0.4% of the agent evenly to obtain the mixed raw materials; pour the above mixed raw materials into the barrel of the twin-screw machine, adjust the screw speed and the main feeding speed, add 40% of the alkali-free long glass fiber, and extrude and granulate under suitable process conditions. The halogen-free flame-retardant reinforced PA66 pellets were obtained. The process conditions are: the temperature of the feeding section in the first zone is 260-290°C, the temperature of the compression section in the second zone is 260-280°C, the temperature in the metering section of the third zone is 250-280°C, the temperature of the head in the fourth zone is 270°C, and the screw speed is 550RPM.

[0040] Among them, the mixed raw materials are added at the main f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com