Flame-retardant nylon composite and preparation method and application thereof

A technology for flame-retardant nylon and composites, applied in the field of flame-retardant nylon composites and their preparation, can solve the problems of low CTI value and insufficient resources of flame-retardant synergist antimony trioxide, etc., and achieve easy industrial production and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

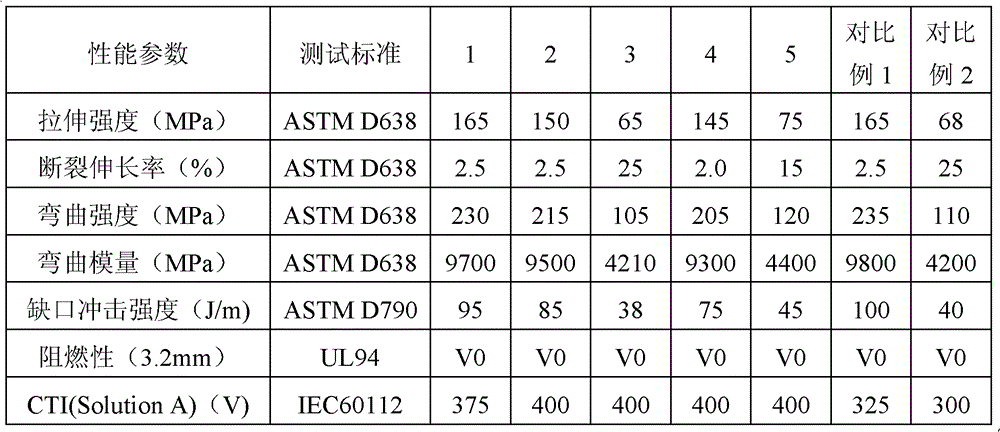

Examples

Embodiment 1

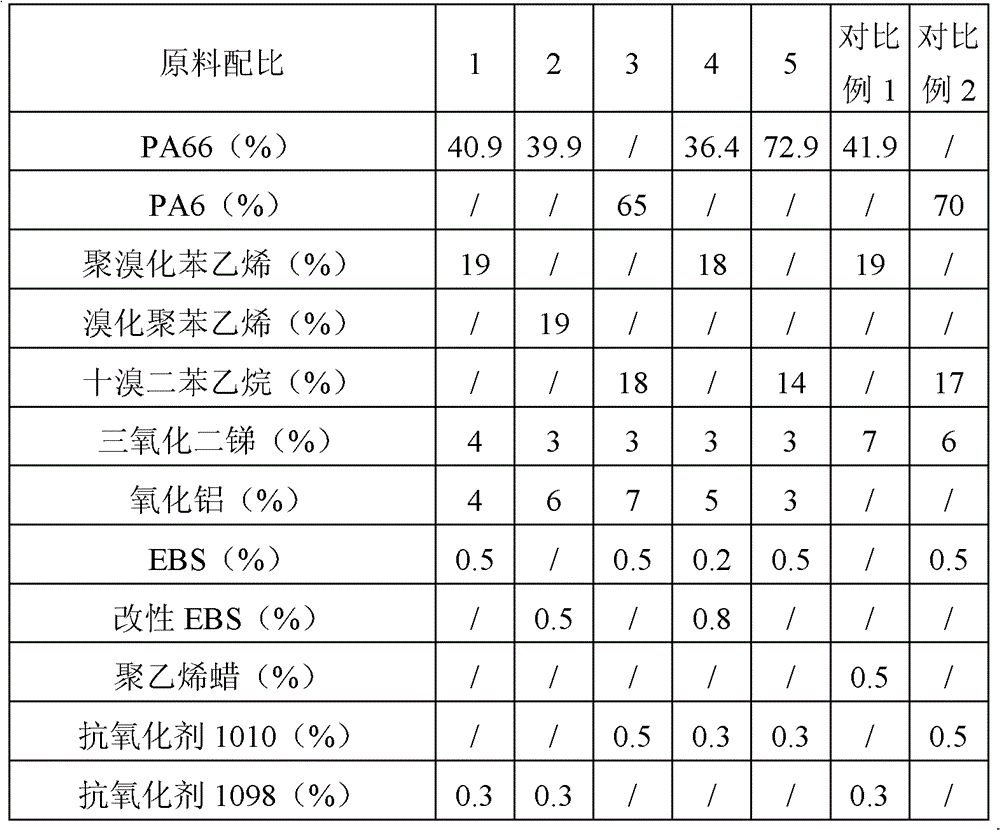

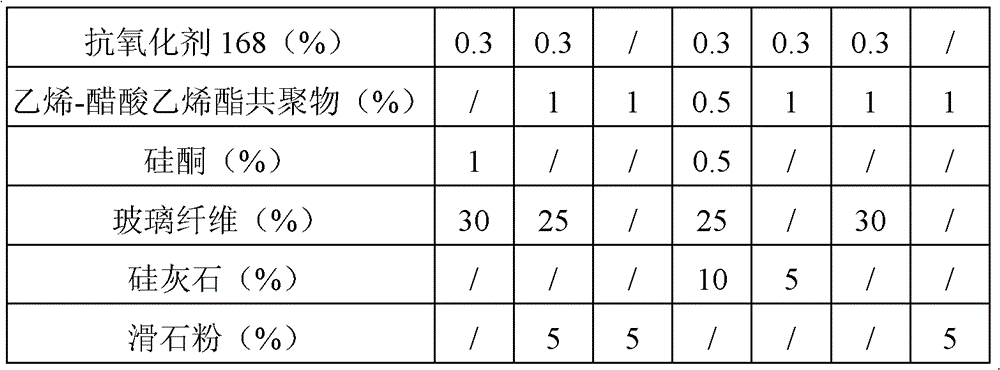

[0038] The raw material formula is shown in Table 1.

[0039] Preparation:

[0040] Add polybrominated styrene, antimony trioxide, aluminum oxide, EBS, antioxidant 1098, antioxidant 168 and silicone into a high-speed mixer and mix evenly, then take out the mixture. Add PA66 from the main feeding port of the twin-screw extruder, add the mixture at the first side feeding port, and then add glass fiber at the second side feeding port, so that all materials are mixed evenly in the twin-screw extruder , extruded, cooled, and pelletized to obtain a flame-retardant nylon compound; the extrusion temperature from the feed section to the machine head is: 240°C, 275°C, 280°C, 275°C, 270°C, 265°C, 265°C, 260°C, die head temperature 270°C.

Embodiment 2

[0042] The raw material formula is shown in Table 1.

[0043] Preparation:

[0044] Add brominated polystyrene, antimony trioxide, aluminum oxide, modified EBS, antioxidant 1098, antioxidant 168 and ethylene-vinyl acetate copolymer into a high-speed mixer and mix evenly, then take out the mixture. Add PA66 from the main feeding port of the twin-screw extruder, add the mixture at the first side feeding port, and then add glass fiber and talcum powder at the second side feeding port, so that all materials are in the twin-screw extruder Mix evenly, extrude, cool, and pelletize to obtain a flame-retardant nylon compound; the extrusion temperature from the feed section to the machine head is: 240°C, 275°C, 280°C, 275°C, 270°C, 265°C, 265°C, 260°C, die head temperature 270°C.

Embodiment 3

[0046] The raw material formula is shown in Table 1.

[0047] Preparation:

[0048] Add decabromodiphenylethane, antimony trioxide, aluminum oxide, EBS, antioxidant 1010 and ethylene-vinyl acetate copolymer into a high-speed mixer and mix evenly, then take out the mixture. Add PA6 from the main feeding port of the twin-screw extruder, add the mixture at the first side feeding port, and then add talcum powder at the second side feeding port, so that all materials are mixed evenly in the twin-screw extruder , extruded, cooled, and pelletized to obtain a flame-retardant nylon compound; the extrusion temperature from the feed section to the machine head is: 210°C, 230°C, 245°C, 245°C, 240°C, 235°C, 230°C, 230°C, die head temperature 235°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com