Low-acid-separation red phosphorus inflaming retarding reinforced polyamide material as well as preparation method and application thereof

A technology of red phosphorus flame retardant and polyamide, which is applied in the field of polymer materials, can solve the problems of heat aging resistance, appearance and electrical properties of modified materials, insufficient mechanical and electrical properties, and decreased electrical insulation properties of materials, etc. problems, to achieve excellent electrical properties, excellent mechanical properties, and maintain the effect of comprehensive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

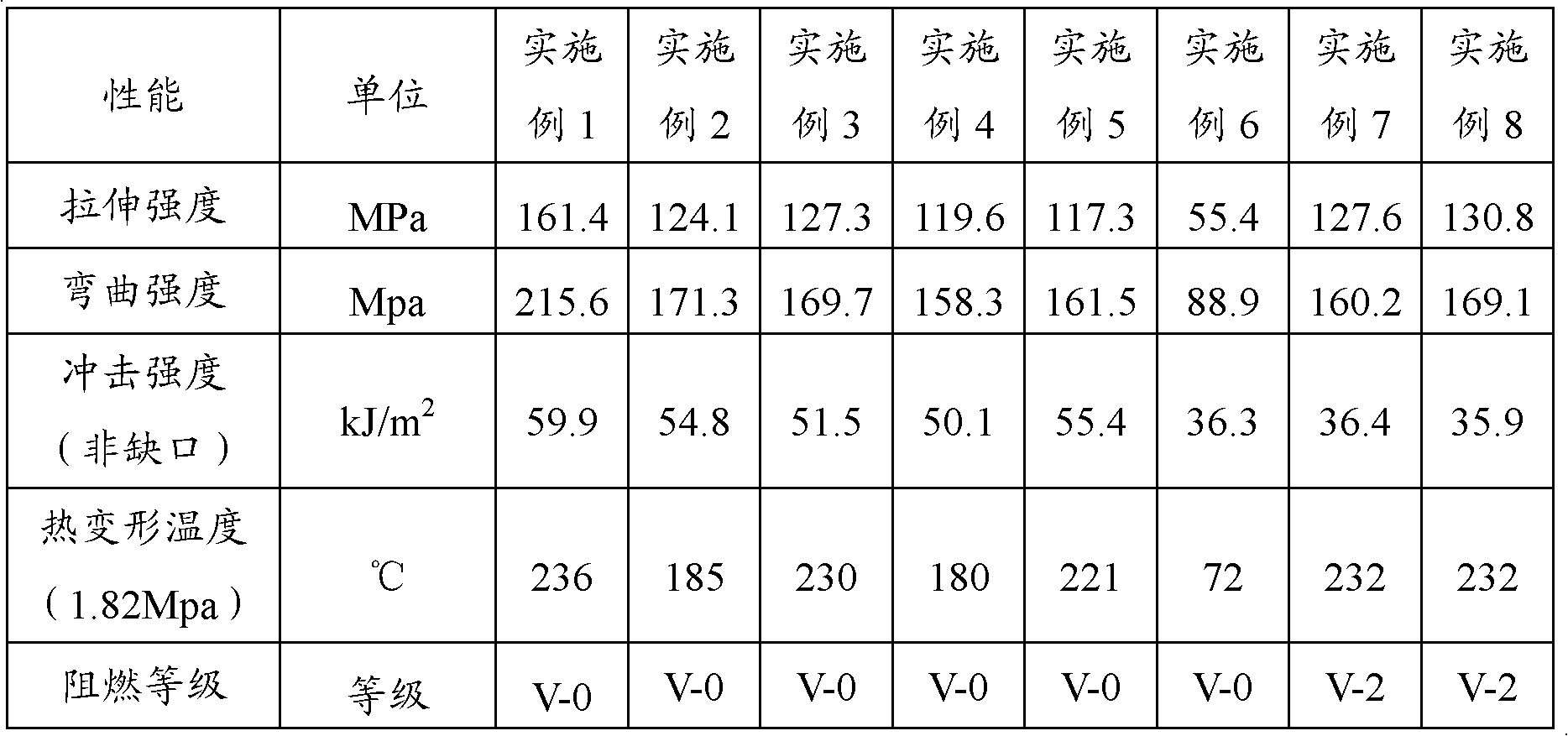

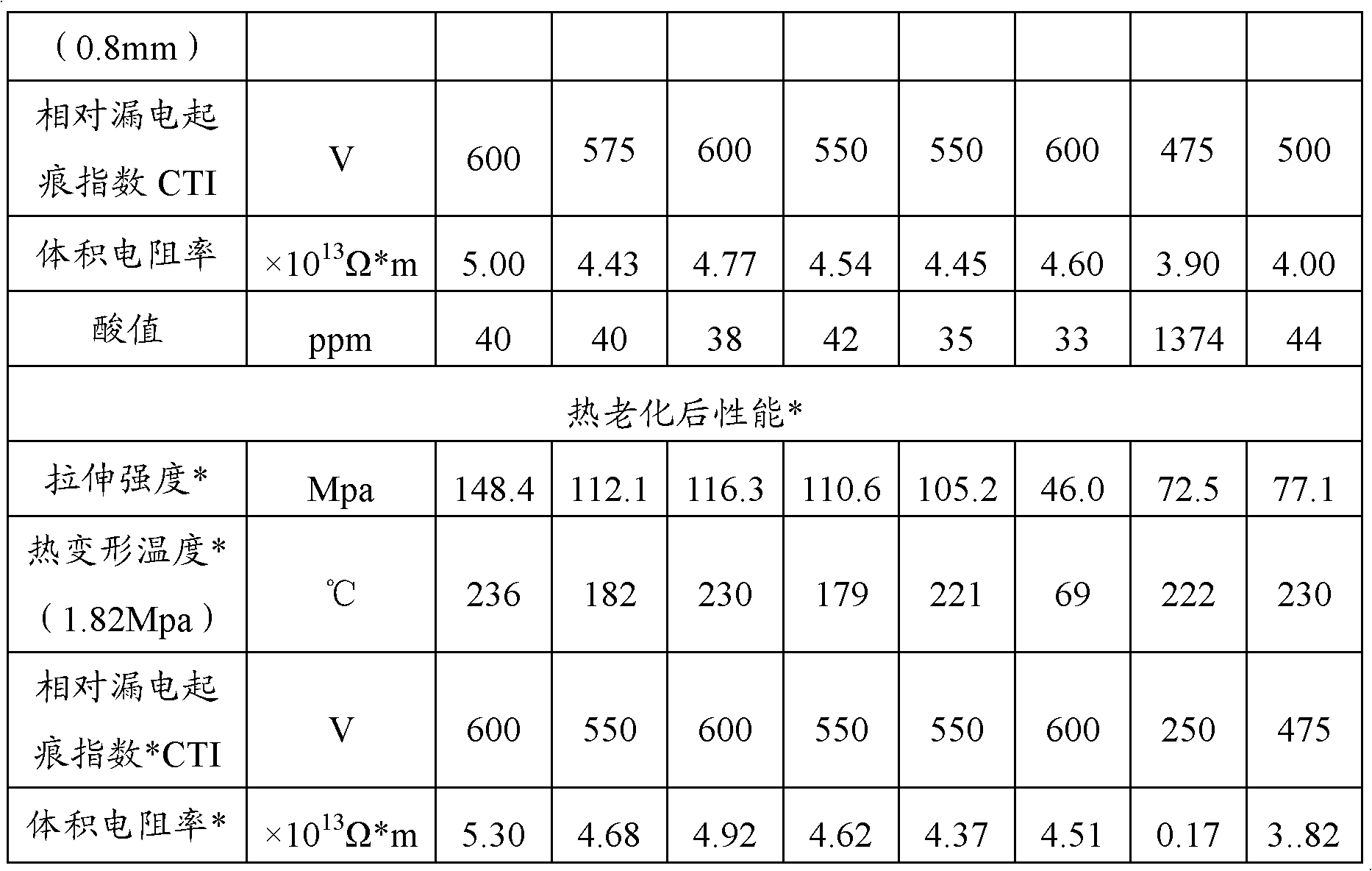

Examples

Embodiment 1

[0041] Adopt the raw material of following weight ratio:

[0042] PA66 (EPR27, Pingdingshan Shenma Engineering Plastics Co., Ltd., percentage by weight moisture content is 0.15%, relative viscosity is 2.7) 53.5Kg;

[0043] Red phosphorus flame retardant (Masterbatch FRP-950 of red phosphorus coated with microcapsules, the weight of red phosphorus accounts for 80% of the total weight of red phosphorus flame retardant, the coating material is melamine formaldehyde resin, and the carrier is polyethylene octene co-elastic Body (POE), Guangzhou Yinsu Flame Retardant Material Co., Ltd.)

[0044] 8Kg;

[0045] Copper oxide (American Albemarle) 2Kg;

[0046] Antioxidant 1098 (hindered phenol stabilizer, Ciba) 0.3Kg;

[0047] Antioxidant 168 (phosphite stabilizer, Ciba) 0.2Kg;

[0048] Modified ethylene bis fatty acid amide (TAF, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.)

[0049] ...

Embodiment 2

[0053] Adopt the raw material of following weight ratio:

[0054] PA6 (M2400, Xinhui Meida Nylon Co., Ltd. of Guangdong Province, the weight percent water content is 0.05%, relative viscosity is 2.45) 53.5Kg;

[0055] Red phosphorus flame retardant (Masterbatch FRP-950 of red phosphorus coated with microcapsules, the weight of red phosphorus accounts for 80% of the total weight of red phosphorus flame retardant, the coating material is melamine formaldehyde resin, the carrier is POE, Guangzhou Yinplastic Flame Retardant Material Co., Ltd.) 8Kg;

[0056] Zinc oxide (American Albemarle) 2Kg;

[0057] Antioxidant 1098 (hindered phenol stabilizer, Ciba) 0.3Kg;

[0058] Antioxidant 168 (phosphite stabilizer, Ciba) 0.2Kg;

[0059] Modified ethylene bis fatty acid amide (TAF, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.)

[0060] 1Kg;

[0061] Alkali-free glass fiber (type 988A, Jushi Group) 35Kg;

[0062] The raw materia...

Embodiment 3

[0064] Adopt the raw material of following weight ratio:

[0065] PA66 (EPR27, Pingdingshan Shenma Engineering Plastics Co., Ltd., percentage by weight moisture content is 0.15%, relative viscosity is 2.7) 47.4Kg;

[0066] Red phosphorus flame retardant (microcapsule coated red phosphorus masterbatch FR9240, the weight of red phosphorus accounts for 40% of the total weight of red phosphorus flame retardant, the coating material is melamine resin, the carrier is PA6, Tongcheng Xinde Chemical Co., Ltd. company) 14Kg;

[0067] Zinc oxide (American Albemarle) 2Kg;

[0068] Antioxidant 1098 (hindered phenol stabilizer, Ciba) 0.5Kg;

[0069] Antioxidant 168 (phosphite stabilizer, Ciba) 0.5Kg;

[0070] Modified ethylene bis fatty acid amide (TAF, Suzhou Xingtai Photochemical Auxiliary Co., Ltd.)

[0071] 0.6Kg;

[0072] Alkali-free glass fiber (type 988A, Jushi Group) 35Kg;

[0073] The raw materials of the above-mentioned we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com