Preparation method of polyarylene sulfide film

A polyarylene sulfide and film technology, which is applied in the field of polyarylene sulfide film preparation, can solve the problems of inability to prepare high-toughness films, high resin crystallinity, and many reaction by-products, etc., and achieves easy processing and high molecular weight. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

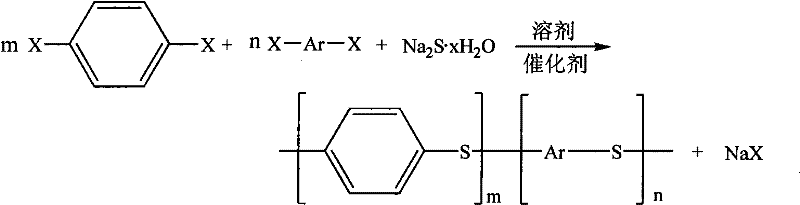

Method used

Image

Examples

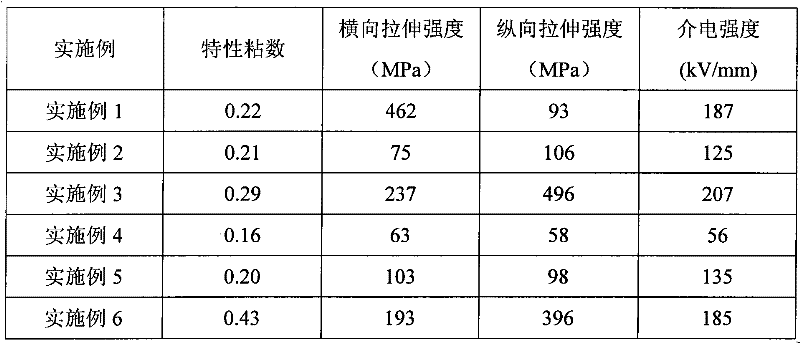

Embodiment 1

[0034] Add 100g of sodium benzoate, 80g of p-aminotoluene, 20g of sodium hydroxide and 600g of dimethylacetamide into a reaction kettle equipped with a nitrogen inlet and outlet, a water separator, a stirrer and a thermometer. After stirring evenly, add 60% 130g of sodium sulfide was dehydrated at a temperature of 160°C for 3 hours under the protection of nitrogen to obtain dehydrated Na 2 S solution, to be the above Na 2 When the temperature of the S solution drops to 80°C, add 117.6g of p-dichlorobenzene and 43.6g of 4,4'-difluorobenzophenone, react at a temperature of 180°C for 8 hours, and then keep it at 250°C for 8 hours. The liquid was hot filtered to separate the solvent and the polymer. After the polymer was washed and dried, it was purified with deionized water and acetone, and dried at a temperature of 120°C and a vacuum of 0.09 MPa for 24 hours to obtain a film-grade polyarylene sulfide resin. The yield was 87%, and the intrinsic viscosity η=0.22.

[0035] The ab...

Embodiment 2

[0037] Add 5g of trisodium phosphate, 20g of sodium p-aminobenzenesulfonate, 100g of sodium bicarbonate and 200g of hexamethylphosphoric triamide into a reaction kettle with a nitrogen inlet and outlet, a water separator, a stirrer and a thermometer, and stir evenly , adding 130 g of sodium sulfide with a content of 60%, under the protection of nitrogen, dehydration reaction at a temperature of 200 ° C for 3 hours, to obtain Na after dehydration 2 S solution, to be the above Na 2 When the temperature of the S solution drops to 150°C, add 132.3g p-dichlorobenzene and 14.7g m-dichlorobenzene, react at a temperature of 250°C for 1 hour, then keep at 300°C for 3 hours, heat filter the reaction solution, and separate the solvent And the polymer, the polymer is washed and dried, then purified with deionized water and acetone, and dried at a temperature of 120° C. under a vacuum of 0.09 MPa for 24 hours to obtain a film-grade polyarylene sulfide resin. The yield is 85%, and the intr...

Embodiment 3

[0040] Add 10g of lithium chloride, 20g of ε-aminocaproic acid, 10g of potassium carbonate and 500g of sulfolane into a reaction kettle with a nitrogen inlet and outlet, a water separator, a stirrer and a thermometer, and after stirring evenly, add sulfide with a content of 60%. Sodium 130g, under the protection of nitrogen, dehydration reaction at a temperature of 180 ° C for 0.5 hours to obtain the dehydrated Na 2 S solution, to be the above Na 2 When the temperature of the S solution drops to 110°C, add 132.3g of p-dichlorobenzene and 28.7g of 4,4'-dichlorodiphenyl sulfone, react at a temperature of 180°C for 3 hours, and then keep it at 280°C for 4 hours. Heat filtration to separate the solvent and the polymer. After the polymer is washed and dried, it is purified with deionized water and acetone, and dried at a temperature of 120°C and a vacuum of 0.09 MPa for 24 hours to obtain a film-grade polyarylene sulfide resin. The yield is 89%, and the intrinsic viscosity η=0.29....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com