Vapor depositing in-situ reaction process for preparing carbon nanotube reinforced copper-base composite material

A copper-based composite material, carbon nanotube technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of destroying the original properties of carbon nanotubes, and achieve improved mechanical properties and thermal properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

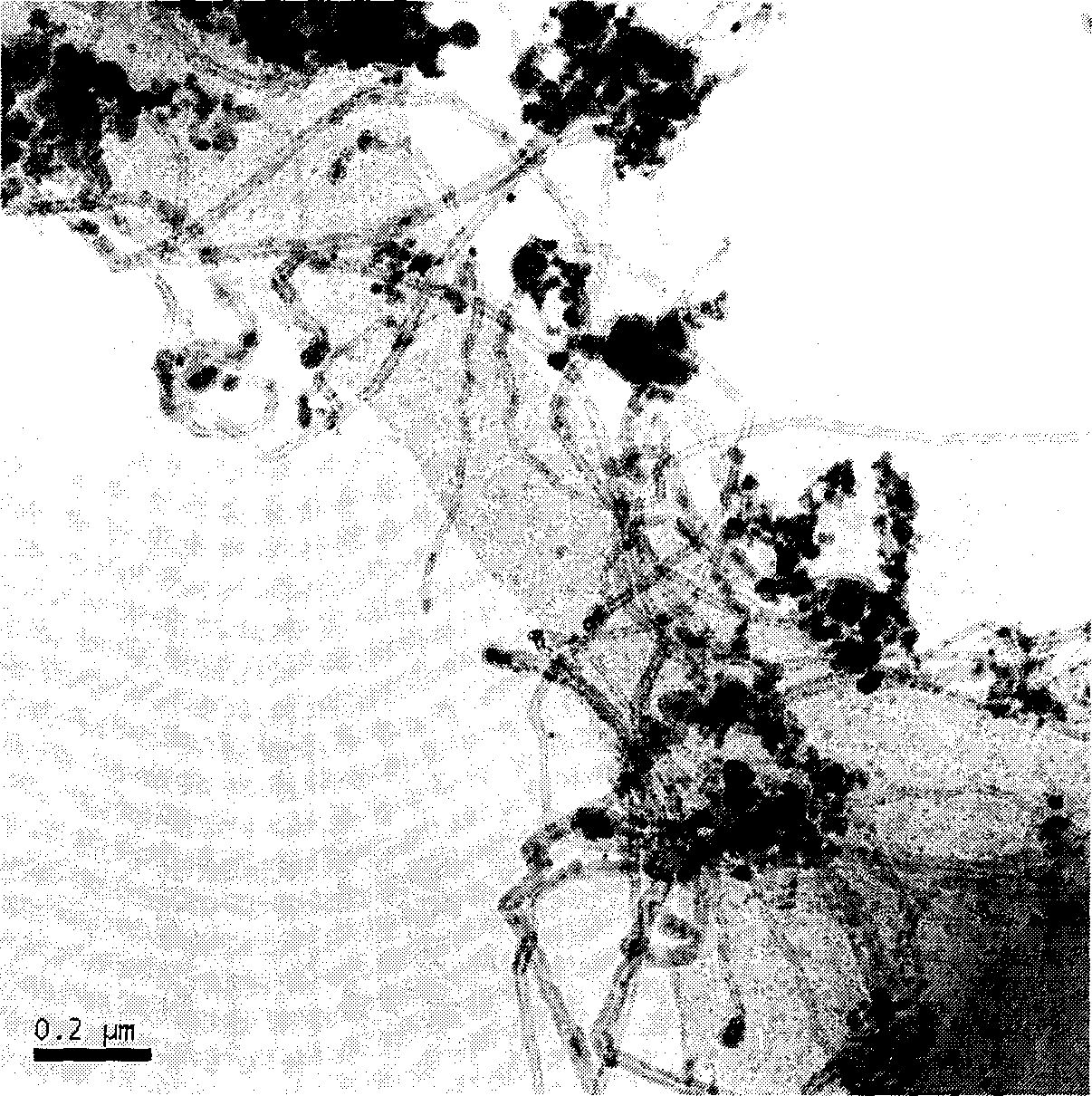

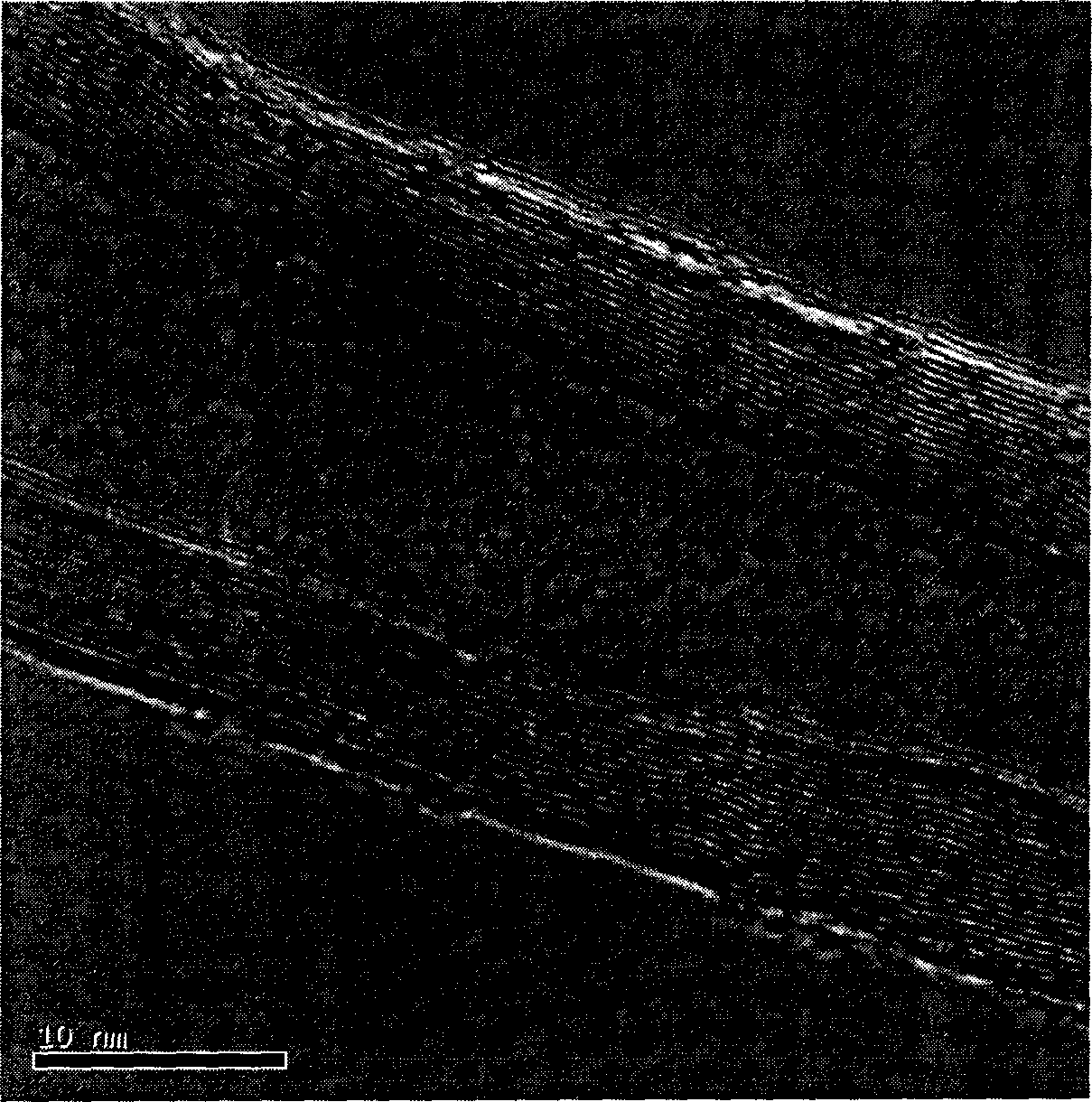

Embodiment 1

[0018] After immersing 18g of electrolytic copper powder in 30mL of absolute ethanol for several hours, it was mixed with 7.926g of nickel nitrate hexahydrate and 1.723g of yttrium nitrate hexahydrate to make 363mL aqueous solution, and then 2.721g of sodium hydroxide was made into 272mL aqueous solution under magnetic stirring. Add dropwise to the above solution to obtain Ni(OH) 2 / Y(OH) 3 / Cu ternary colloid; the ternary colloid is washed and filtered, dehydrated and dried in a vacuum drying oven at 80°C, ground with an agate mortar, and calcined at 400°C under nitrogen protection for 2h to obtain Ni / Y / Cu catalyst Precursor. Then take 2g of Ni / Y / Cu catalyst precursor, raise the temperature to 500°C under the protection of nitrogen, stop the nitrogen, pass in hydrogen for reduction, and the hydrogen flow rate is 80 mL / min. After keeping for 4 hours, turn off the hydrogen, turn on the nitrogen and continue heating to 550°C, and then pass in a mixed gas of nitrogen and methane (nit...

Embodiment 2

[0020] After soaking 38g of electrolytic copper powder in 30mL of absolute ethanol for several hours, make 363mL of aqueous solution with 7.926g of nickel nitrate hexahydrate and 1.723g of yttrium nitrate hexahydrate, and then make 2.721g of sodium hydroxide into 272mL of aqueous solution, under magnetic stirring Add dropwise to the above solution to obtain Ni(OH) 2 / Y(OH) 3 / Cu ternary colloid; the ternary colloid is washed and filtered, dehydrated and dried in a vacuum drying oven at 150°C, ground with an agate mortar, and calcined at 400°C under nitrogen protection for 2h to obtain Ni / Y / Cu catalyst Precursor. Then take 2g of Ni / Y / Cu catalyst precursor, raise the temperature to 500°C under the protection of nitrogen, stop the nitrogen, and pass in hydrogen for reduction, and the hydrogen flow rate is 200 mL / min. After holding for 1.5h, turn off the hydrogen, turn on the nitrogen and continue heating to 700°C, and then pass in a mixed gas of nitrogen and methane (nitrogen flow ra...

Embodiment 3

[0022] After soaking 38g of electrolytic copper powder in 30mL of absolute ethanol for several hours, make 363mL of aqueous solution with 7.926g of nickel nitrate hexahydrate and 1.723g of yttrium nitrate hexahydrate, and then make 2.721g of sodium hydroxide into 272mL of aqueous solution, under magnetic stirring Add dropwise to the above solution to obtain Ni(OH) 2 / Y(OH) 3 / Cu ternary colloid; the ternary colloid is washed and filtered, dehydrated and dried in a vacuum drying cabinet at 100°C, ground with an agate mortar, and calcined at 400°C under nitrogen protection for 2h to obtain Ni / Y / Cu catalyst Precursor. Then take 2g of Ni / Y / Cu catalyst precursor, heat up to 400°C under the protection of nitrogen, stop the nitrogen, pass in hydrogen for reduction, and the flow rate of hydrogen is 100mL / min. After keeping for 4 hours, turn off the hydrogen and pass in a mixed gas of nitrogen and methane (nitrogen flow rate is 420mL / min, methane flow rate is 60mL / min) and react for 1 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com