Chip separation method for 3D stacked chip encapsulator

A technology of chip packaging and separation method, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc. Electrical measurement analysis, the effect of avoiding inclined grinding damage, avoiding forced cracking or warping damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

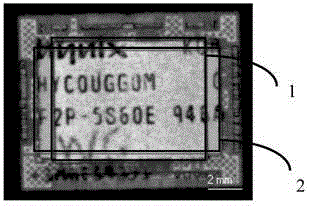

[0038] In this embodiment, the memory containing two chips of NAND Flash+Mobile SDRAM (the two-layer chips adopt the form of cross-stacking) is taken as an example, and the second layer of chips is obtained by separation. The separation method includes the following steps (for the technical flow chart, see figure 1 ):

[0039] (1) Determine the grinding area and its area

[0040] Scanning Acoustic Microscopy (C-SAM) memory internal structure such as figure 2 As shown, the memory is a cross-type double-sided lead package, in which, 1 is the first layer chip, and 2 is the second layer chip; the packaging material and 1 the first layer chip are determined to be the grinding area, and the area is 8mm; at the same time, the memory initial The thickness is about 1mm. According to experience, usually the uppermost packaging material accounts for about 1 / 3 of the total thickness of the memory, which provides a reference for the grinding force when grinding the packaging material in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com