Catalyst for preparing olefin by dehydrogenating low-carbon alkane, and preparation method and application thereof

A low-carbon alkane and catalyst technology is applied in the field of preparation of basic organic chemical raw materials, and achieves the effects of simple preparation method, large choice and moderate acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

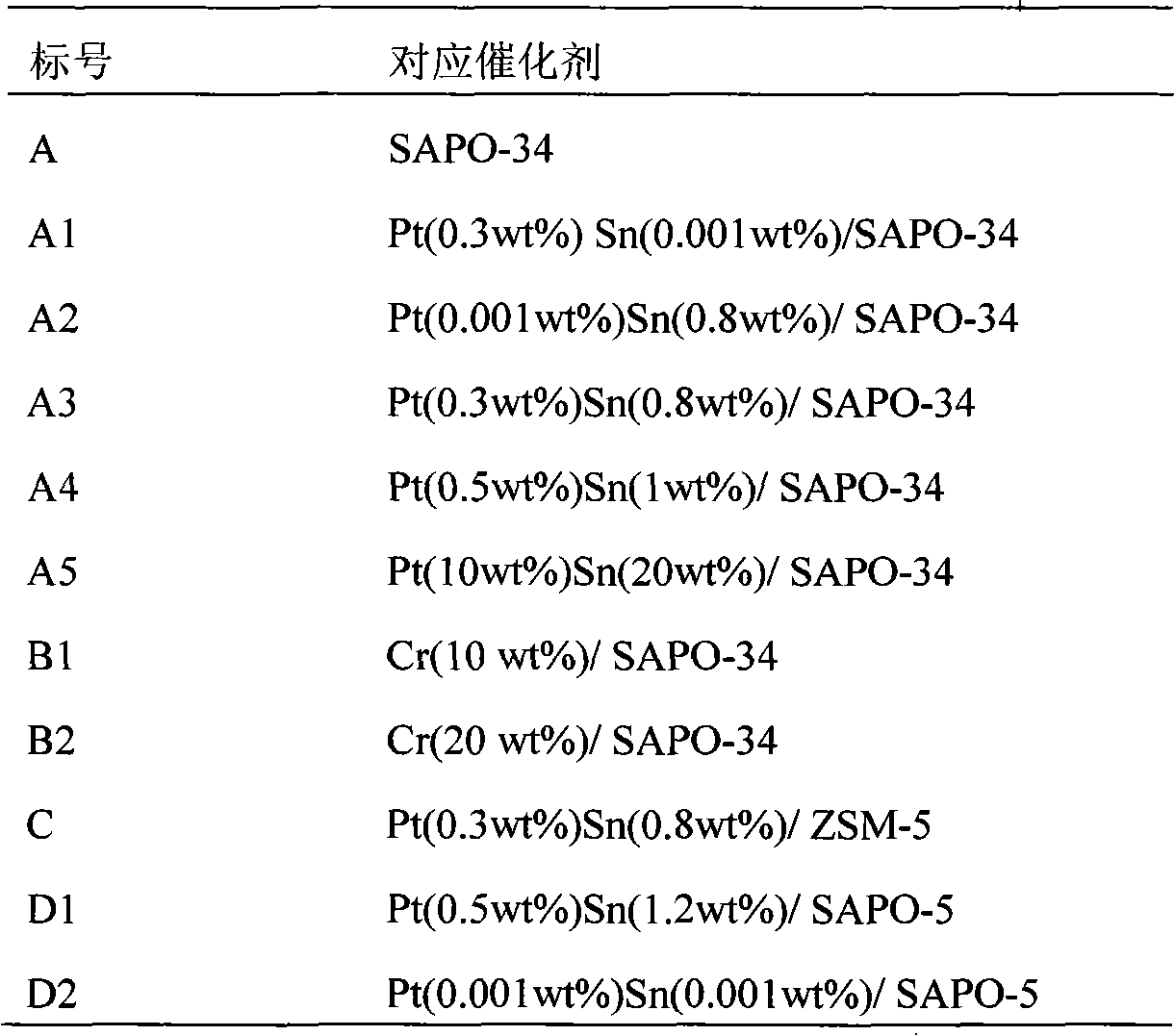

[0026] The invention relates to a catalyst for preparing olefins by dehydrogenating low-carbon alkanes, including propane, butane and pentane, as well as its preparation method and application. The catalyst uses silicoaluminophosphate molecular sieve as a carrier, group VIII or VIB group elements as active components, group IVA elements as auxiliary agents, and dehydrogenates low-carbon alkanes to olefins under preferred reaction conditions. The reactor uses Fixed bed, moving bed reactor, or fluidized bed reactor.

[0027] A catalyst for the dehydrogenation of low-carbon alkanes to olefins provided by the present invention uses silicoaluminophosphate molecular sieves as a carrier, VIII or VIB group elements as active components, and IVA group elements as auxiliary agents. The weight percentage of the catalyst is 0.001-20%, and the auxiliary agent is 0.001-20% of the weight of the catalyst; the low-carbon alkanes include propane, butane and pentane. Described silicoaluminophos...

Embodiment 1

[0042] This example illustrates the preparation of the SAPO-34-supported propane dehydrogenation catalyst of the present invention.

[0043] First SAPO-34 molecular sieve in 0.16M SnCl 2 .2H 2 Immerse in O solution at 80° C. for 10 hours, the Sn loading in the catalyst reaches 0.001˜20 percent (mass percentage), and then dry at 120° C. for 6 hours. The dried samples were then calcined in an air atmosphere in a muffle furnace at a temperature of 550° C. for 4 hrs. Calcined Sn / SAPO-34 powder with 0.03M H 2 PtCl 6 ·6H 2 The O solution was impregnated at 80° C. for 4 hours, so that the Pt content in the final catalyst was 0.001-10%. It was then dried at 120°C for 6hrs, and then fired in a muffle furnace at 550°C for 4hrs. Prior to reaction evaluation, all catalyst samples were dechlorinated with steam at 500°C for 8 hr; then reduced with hydrogen at 550°C for 12 hr. By changing the content of Pt and Sn in the catalyst, A1-A5 catalysts were prepared respectively.

[0044] A...

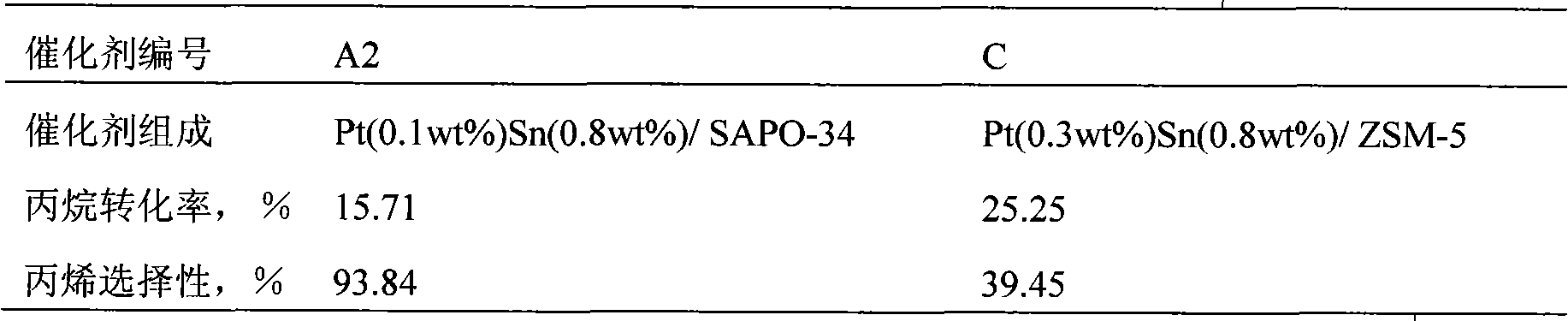

Embodiment 2

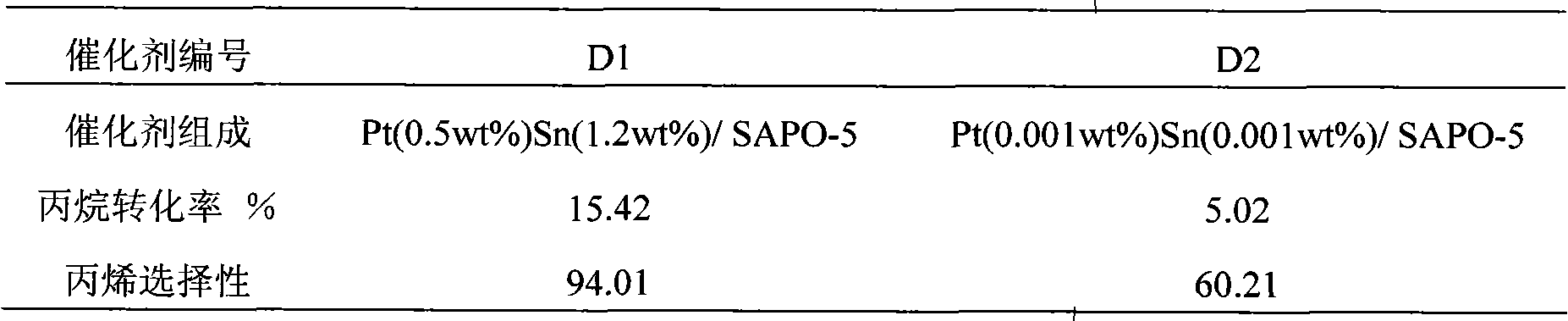

[0049] This example illustrates the preparation of the SAPO-5-supported propane dehydrogenation catalyst of the present invention.

[0050] According to the method described in embodiment 1, at first SAPO-5 molecular sieve is in the SnCl of 0.16M 2 .2H 2 Immerse in O solution at 90° C. for 4 hours, the loading amount of tin in the catalyst reaches 0.5-2% (mass percentage), and then dry at 120° C. for 10 hours. These samples were then fired in a muffle furnace under air atmosphere for 4 hrs at a firing temperature of 400°C. Calcined Sn / SAPO-5 powder with 0.01M H 2 PtCl 6 ·6H 2 The O solution was impregnated at 90 °C for 4 hr, so that the Pt content in the final catalyst was 0.001-1%. Then dry at 120°C for 6hr, and then bake at 550°C for 4hr in a muffle furnace. The prepared catalysts D1 and D2 are composed of (Pt (0.5wt%) Sn (1.2wt%) / SAPO-5) and (Pt (0.001 wt%) Sn (0.001 wt%) / SAPO-5). Prior to reaction evaluation, all catalyst samples were dechlorinated with steam at 500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com