Method for producing hot-bending elbow

A process method and technology for hot simmering pipe bends, which are applied in the field of metal pipe processing and piping systems, can solve the problems of unsatisfactory quality of pipe bends, not strict enough quality of pipe bends, and not rigorous enough production methods. Rigorous, stable quality and safe production process

Inactive Publication Date: 2010-08-25

CHINA PETROLEUM PIPELINE BUREAU +1

View PDF0 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because the production method is not strict enough, the quality control of the bent pipe is not strict enough, so the quality of the bent pipe is not satisfactory.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

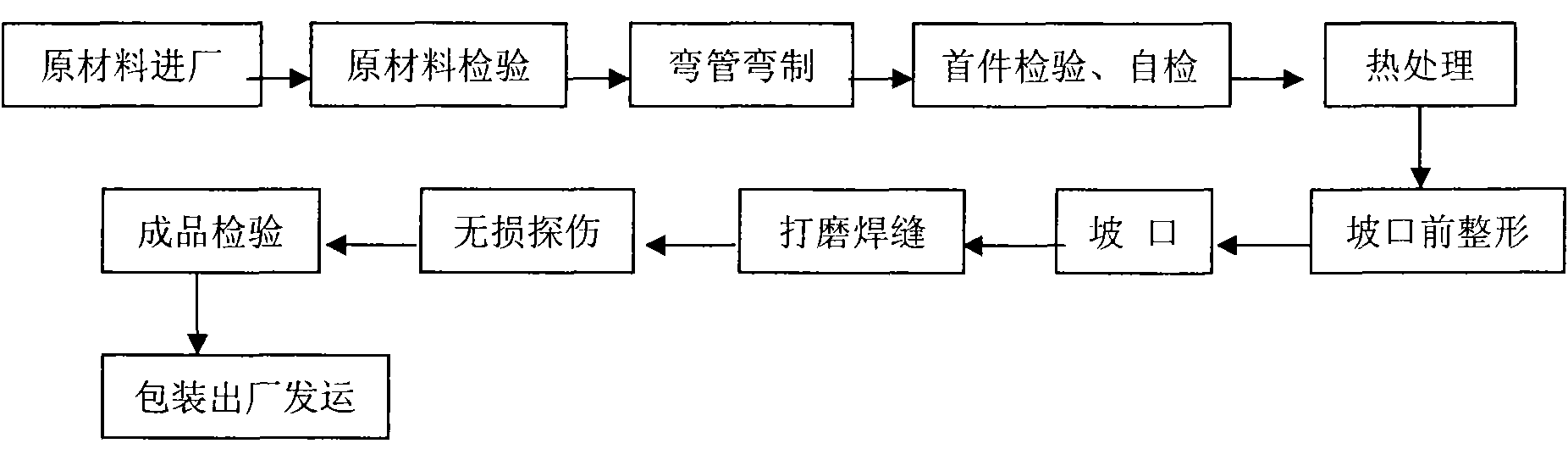

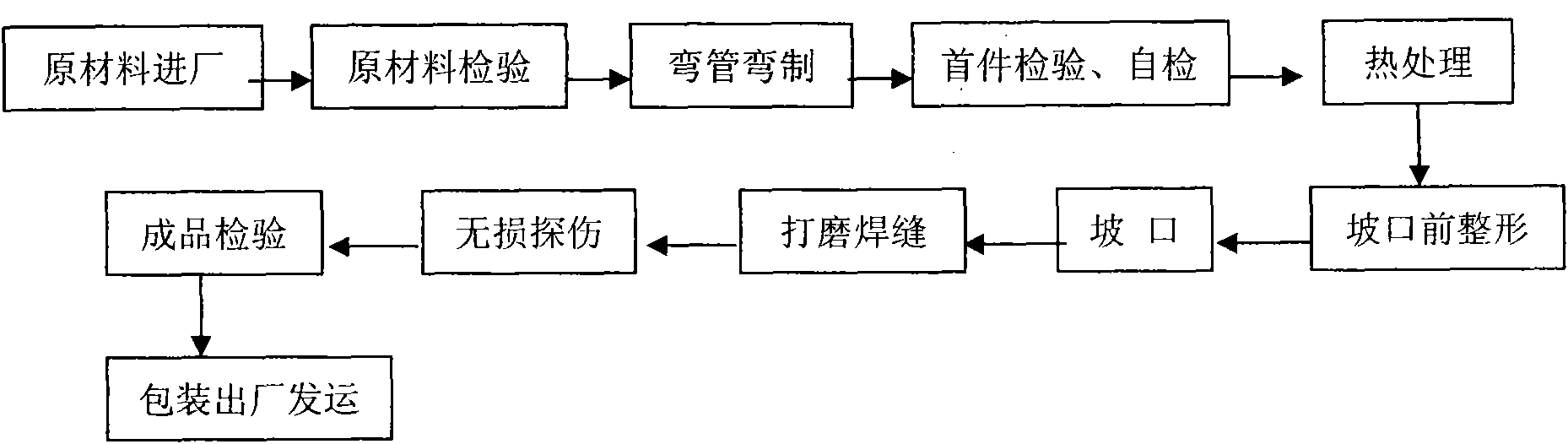

The invention discloses a method for producing a hot-bending elbow, and relates to the technical field of treatment of metal pipes and piping systems. The method comprises the following steps: purchasing raw materials, and storing; inspecting the raw materials; bending to obtain the elbow; carrying out first sample inspection and self-inspection; heat-treating; shaping before beveling; beveling; grinding welding seams; carrying out nondestructive inspection; carrying out product inspection; and packing, and sending the finished products out of the factory. From purchasing the raw materials to sending the finished products out of the factory, the invention specifies a complete and strict technological process. Thus, the invention has the advantages of safe production process, high speed, controllability and stable quality, and is a refined method for producing hot-bending elbows.

Description

Hot simmering pipe bending process technical field The invention relates to a hot-simmering pipe bending process. It relates to the technical field of processing of metal pipes and piping systems. Background technique Bend pipe is a pipe material widely used in pipeline construction, and it is one of the important key products. It plays a major role in the pipeline, one is to change the direction of the pipeline, and the other is the structural mechanics, which can buffer the tensile and compressive stress and torque added to the straight pipe by the stratum migration, earthquake and external environment temperature changes where the pipeline is located. The performance of the elbow directly affects the reliability, safety and economy of pipeline transportation. Therefore, the processing technology of the bent pipe is particularly important. At present, the processing technology of the bent pipe is basically mature, and the produced bent pipe can basically meet the requ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D7/00B21D9/00

Inventor 李玉卓王永胜郑卫赵玉朋金永英

Owner CHINA PETROLEUM PIPELINE BUREAU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com