Ceramic-plastic floor and processing method thereof

A technology of flooring and porcelain plastic, which is applied in the direction of chemical instruments and methods, layered products, and synthetic resin layered products. High bending strength and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

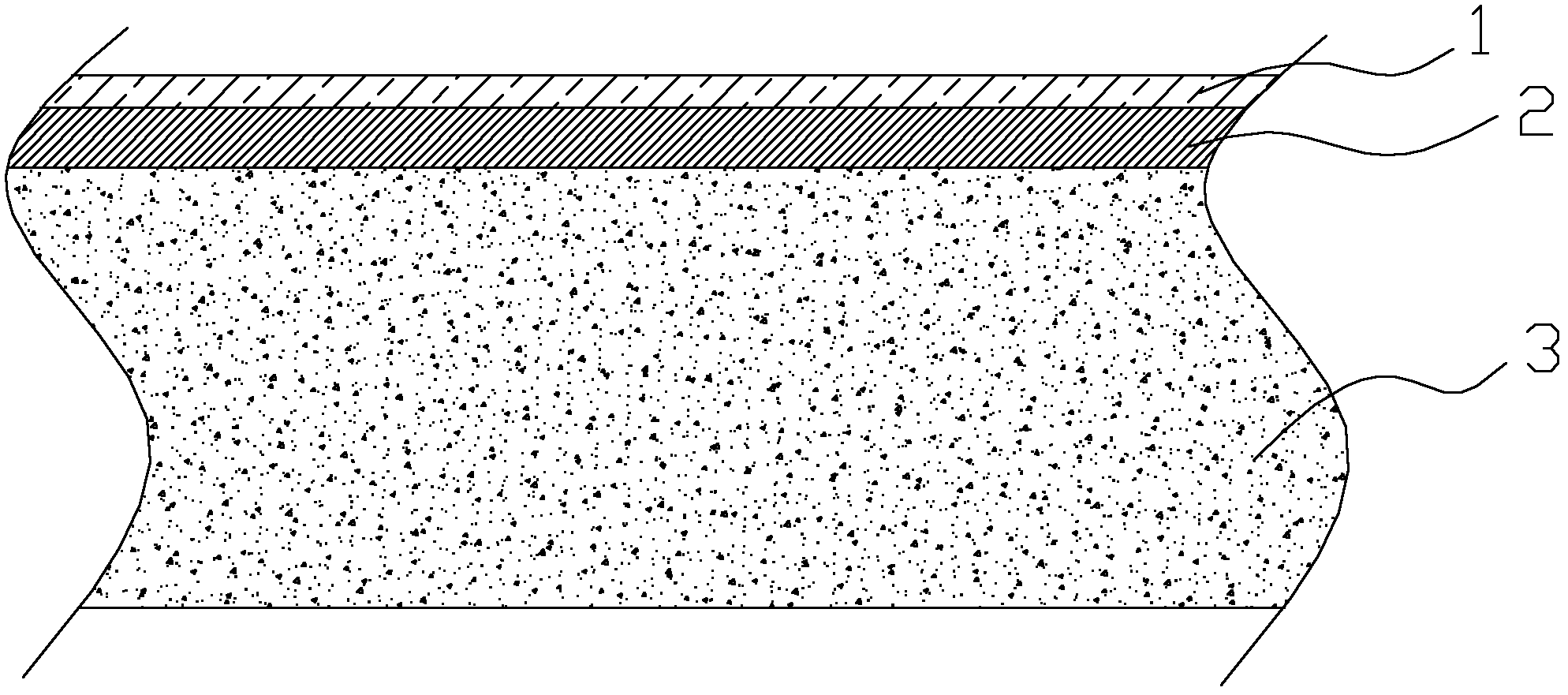

[0028] Such as figure 1 , a porcelain-plastic floor, comprising a PVC transparent wear-resistant layer 1, a PVC pattern printing layer 2, and a primer layer 3 sequentially stacked from top to bottom; wherein the primer layer 3 includes the following components by weight: 100 parts by suspension method Polyvinyl chloride resin, 15 parts of diisononyl phthalate, 1 part of barium stearate, 1 part of zinc stearate, 45 parts of 80 mesh ceramic beads, 90 parts of 250 mesh calcium carbonate stone powder, 0.5 part of rosin and the right amount of colorant.

[0029] The method for processing the above-mentioned porcelain-plastic floor comprises the following process steps:

[0030] (1) Process the bottom material layer; put each component of the bottom material layer into the high-speed mixer according to the weight ratio and mix them uniformly for 5-7 minutes, and send the uniformly mixed mixture into the internal mixer with a temperature of 140-160 °C Carry out internal mixing for ...

Embodiment 2

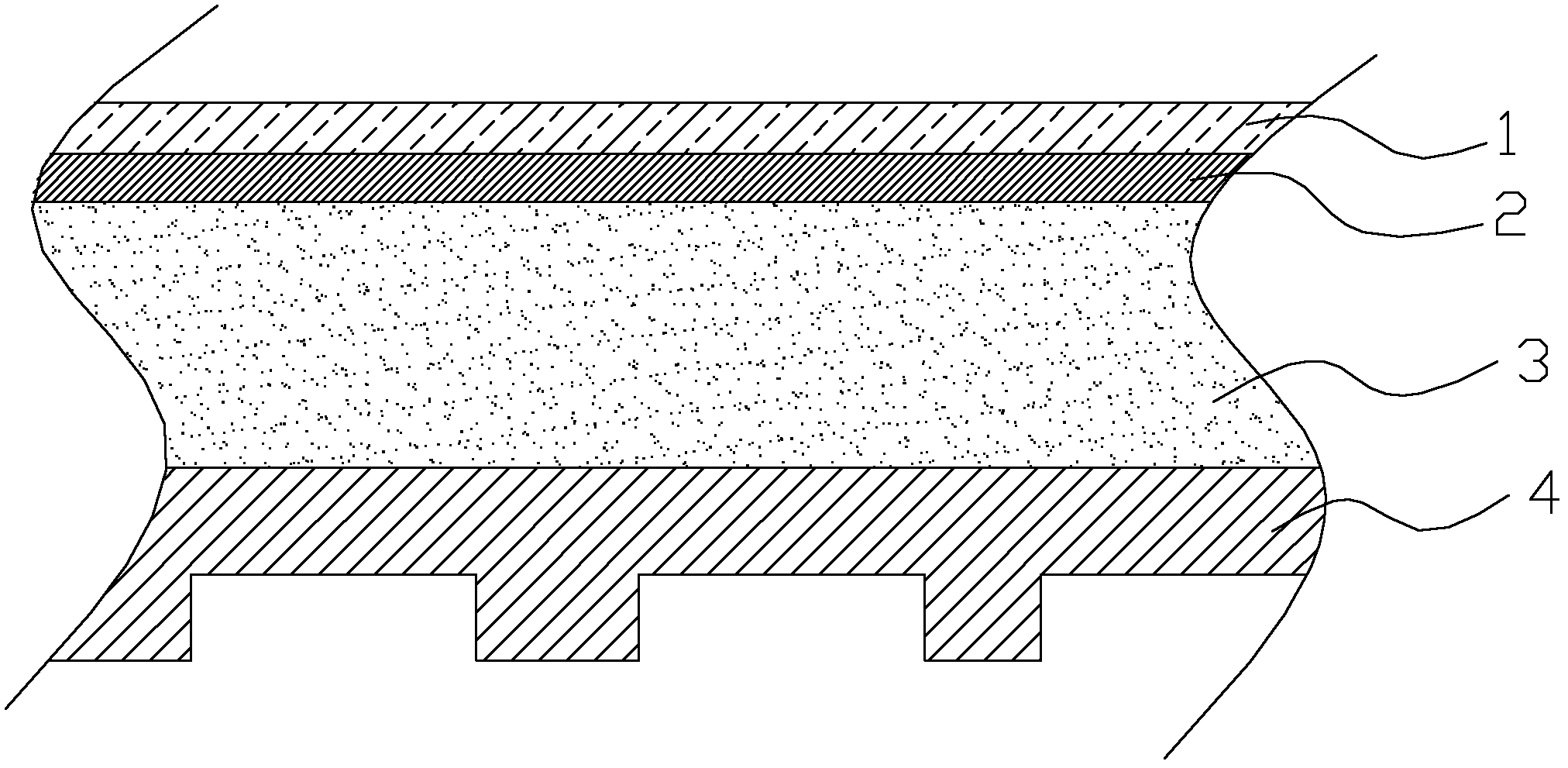

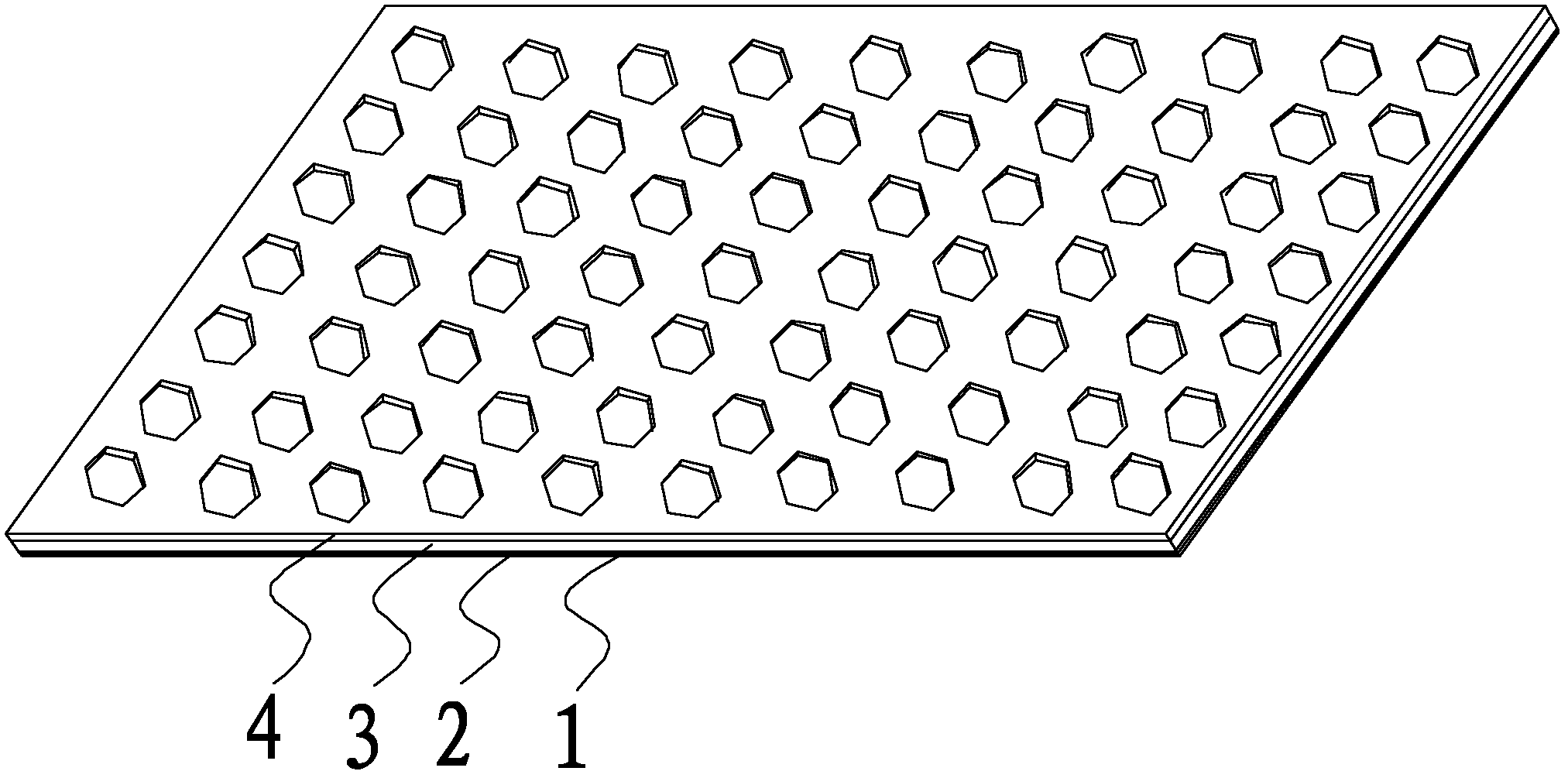

[0037] Such as figure 2 , image 3, a porcelain-plastic floor, comprising a PVC transparent wear-resistant layer 1, a PVC pattern printing layer 2, a primer layer 3 and an elastic adsorption layer 4 stacked sequentially from top to bottom; Concave-convex pattern and the embossed pattern surface of each concavo-convex pattern is the same plane and is closed with a PVC layer of concavity; Primer layer 3 comprises the following components by weight: 100 parts of suspension method polyvinyl chloride resin, 20 parts of ortho Diisononyl phthalate, 2.5 parts of barium stearate, 2.5 parts of zinc stearate, 50 parts of 150 mesh glass microsphere powder, 100 parts of 325 mesh calcium carbonate stone powder and 2 parts of rosin.

[0038] The method for processing the above-mentioned porcelain-plastic floor comprises the following process steps:

[0039] (1) Process the bottom material layer; put each component of the bottom material layer into the high-speed mixer according to the wei...

Embodiment 3

[0046] A porcelain-plastic floor, which is different from Embodiment 1 in that: the four sides of the primer layer 3 are respectively provided with two pairs of matching protrusions and grooves.

[0047] The finished product produced according to the above formula and process meets the requirements of EN649: 1996 (Specification for Homogeneous and Heterogeneous PVC Floor Coverings for Elastic Floor Coverings), heating dimensional shrinkage ≤ 0.20% (standard ≤ 0.25%), warpage ≤ 1.5mm (standard ≤ 2.0), extremely low water absorption (≤ 0.05%), fire performance reaches B1 level, and environmental protection meets GB18586-2001 and EN71 Part3 standards. The hardness is above shoreD65 (ordinary PVC floor shore D 50-58), and the bending strength is above 18MPa. It can completely achieve the effect of imitating wood flooring and ceramic tiles. It is a new substitute for wooden flooring and ceramic tiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Warping | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com