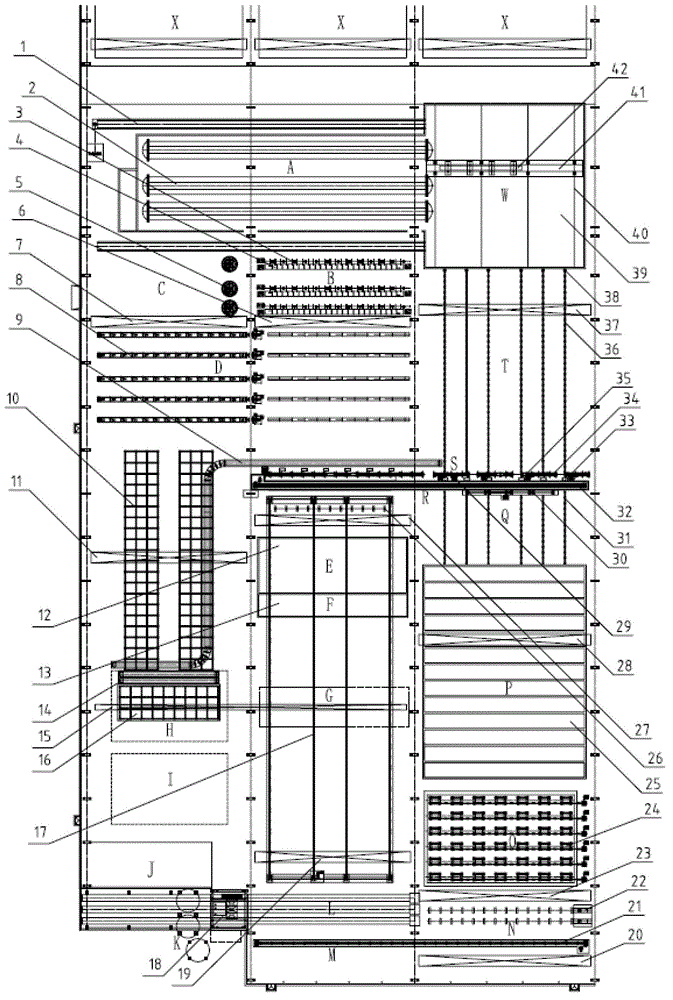

PHC (prestressed concrete pipe pile) pile streamline conveying production line

A PHC pipe pile and production line technology, which is applied in reinforced molding, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of excessive wall thickness deviation of pipe piles, long moving distance of pipe molds, and uneven distribution of materials, so as to shorten the driving time The moving distance and the uniformity of the fabric are easy to check, and the effect of reducing the incidence of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

[0026] See the accompanying drawings for details, a PHC pipe pile flow conveying production line, including left, middle and right three areas to form the entire production workshop, the front end of the workshop is provided with a mold clamping area M, and the rear end of the workshop is equipped with an autoclave steam curing area A , from front to back, the workshops on the left side are set up in order: mixing building K, warehouse and duty room J, end plate processing area I, steel cage and end plate assembly area H, steel cage roll welding area D, steel rods and wire drawing Stacking area C, workshops in the middle area are set up in sequence: concrete distribution area L, cage loading area G, oil spray pool F, mold cleaning pool E, form removal area R, steel rod fine cutting and heading area B, and the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com