Method for recycling red lead process gas

A technology of waste gas circulation and red lead, which is applied in the direction of separation methods, chemical instruments and methods, lead red, etc., can solve the problems that affect people's living environment and health, cannot meet the demand for lead material oxidation, and consume large energy, and achieve protection Good health, reduced energy consumption, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

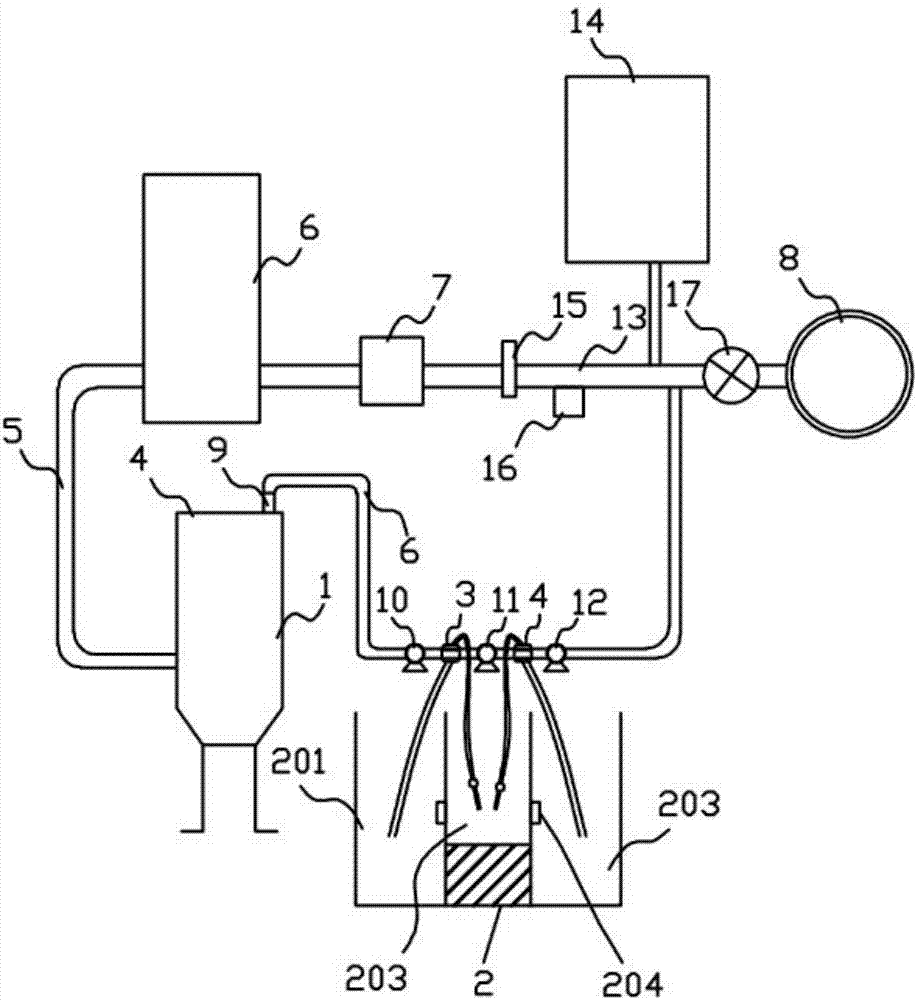

[0032]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0033] A kind of red lead production waste gas recycling method, concrete method is as follows:

[0034] (1) Bag dust removal and cooling

[0035] The exhaust gas in the red lead oxidation furnace is generally around 650°C. Under the action of the centrifugal induced draft fan (mature equipment in the market) (the same below), the exhaust gas is introduced into the bag filter through the first gas pipeline to remove dust and cool down. In the process, about 90% of lead dust particles larger than 0.1 μm in the exhaust gas can settle in the dust collector, and the concentration of lead fume will continue to decrease with the decrease of temperature, but it cannot be completely eradicated;

[0036] (2) Secondary wind "rain curtain filter"

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com