Preparation method of lead oxide

A technology of lead oxide and carbon dioxide, applied in the direction of lead oxide, lead red, lead carbonate, etc., can solve the problems of long process flow, poor economy, high energy consumption, etc., and achieve the effect of simple process, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

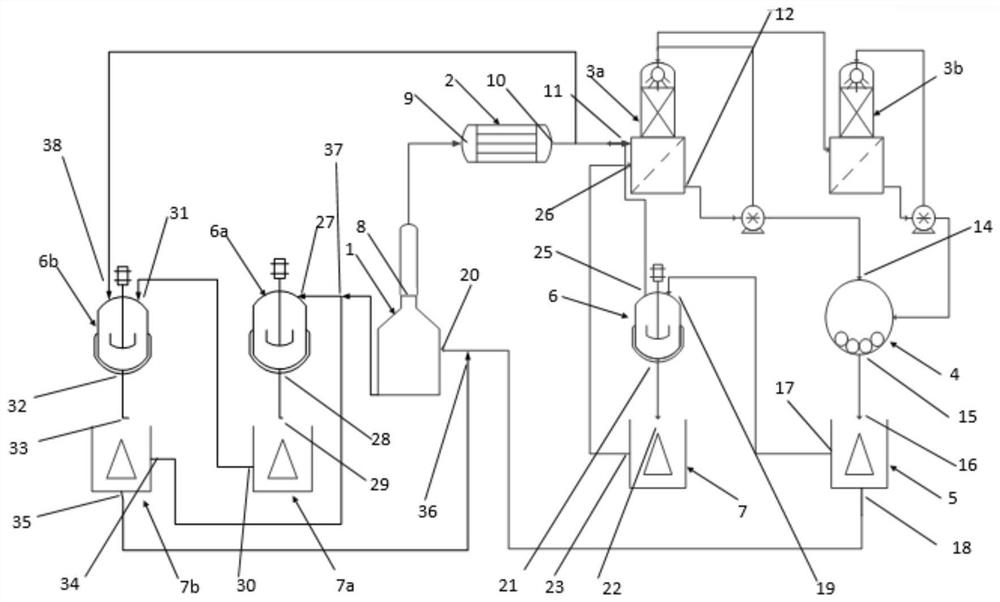

[0015] The present invention will be further described below in conjunction with specific drawings.

[0016] Such as figure 1 As shown, the lead-acid battery cathode material preparation device of the present invention includes a roasting device 1, a heat exchanger 2, a gas purification device 3, a tail gas treatment product conversion device 4, a first solid-liquid separation device 5, a gypsum generating device 6, a second solid Liquid separation device 7, purification device 6a, lead carbonate preparation device 6b, purification solid-liquid separation device 7a, lead carbonate solid-liquid separation device 7b. Roasting device 1 comprises tail gas outlet 8, and tail gas outlet 8 communicates with the inlet 9 of heat exchanger 2, and the exhaust port 10 of heat exchanger 2 communicates with the inlet 11 of gas purification device 3 (3a), and gas purification device 3(3a) The exhaust port 12 is communicated with the feed port 14 of the tail gas treatment product conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com