Vertical read-lead mobile oxidation furnace

A technology of oxidation furnace and red dan, applied in the directions of lead oxide, lead dan, energy input, etc., can solve the problems of low production efficiency, large horizontal furnace body, pollution of the environment, etc., and achieve high production efficiency, good product quality, and structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

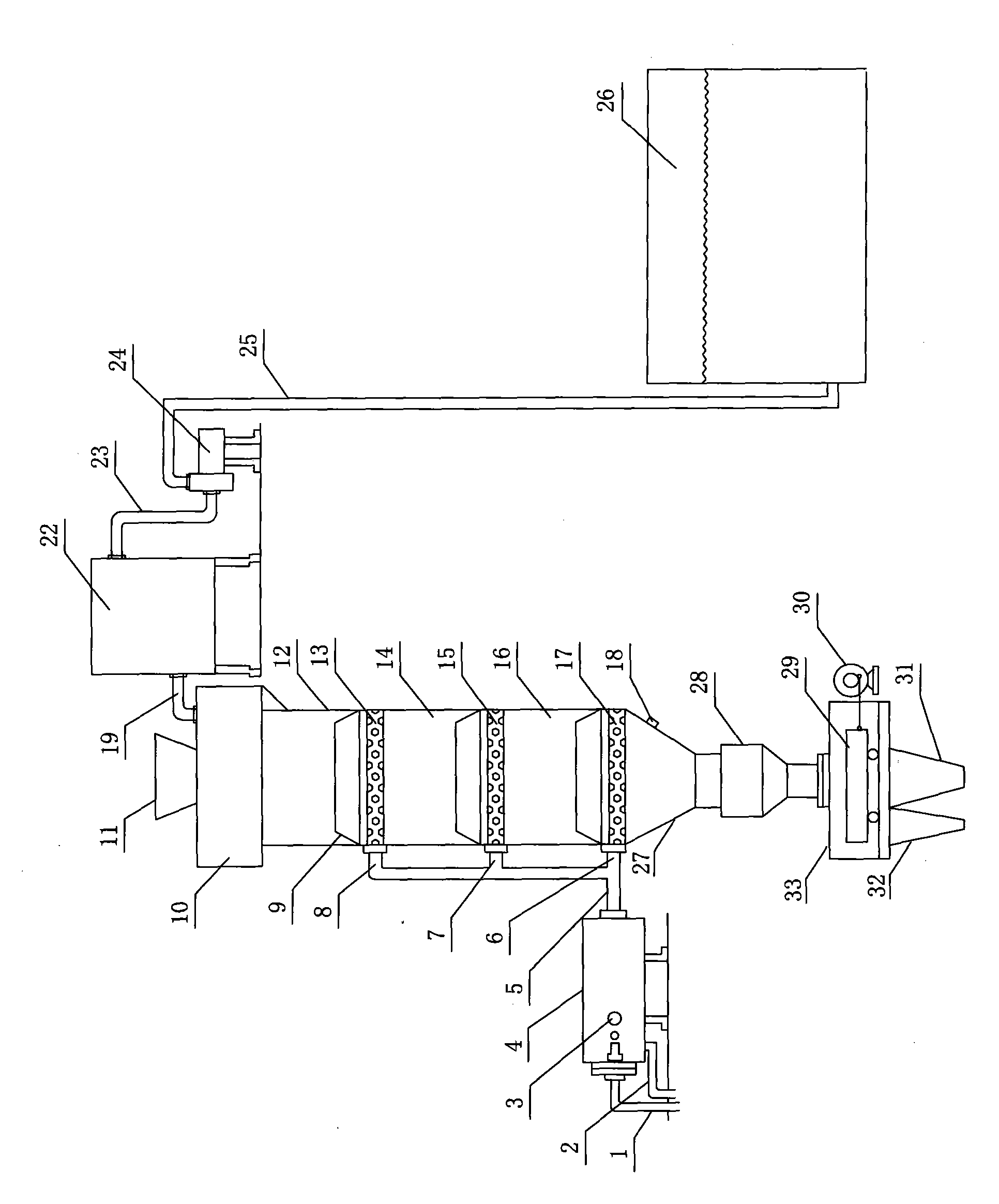

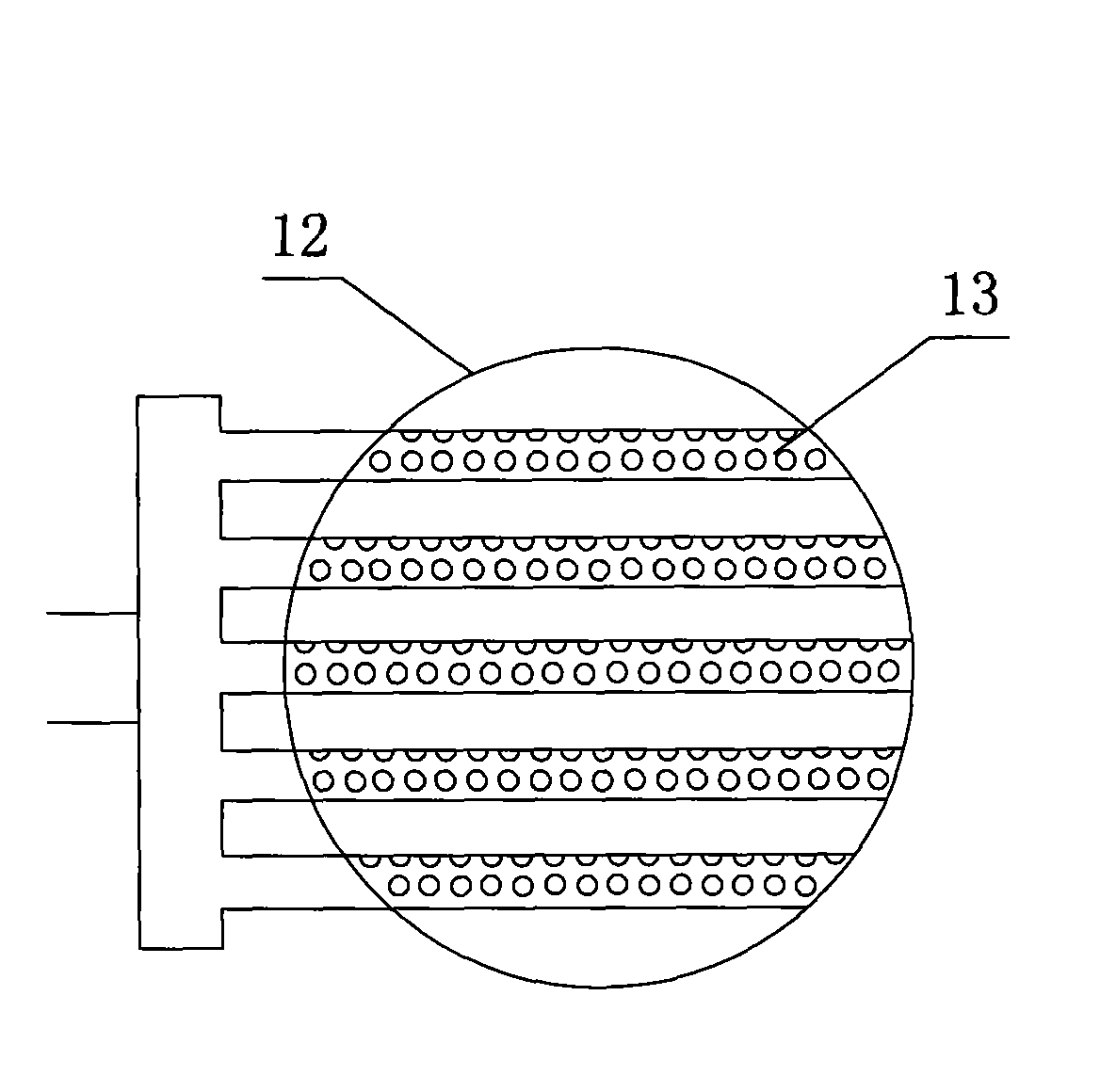

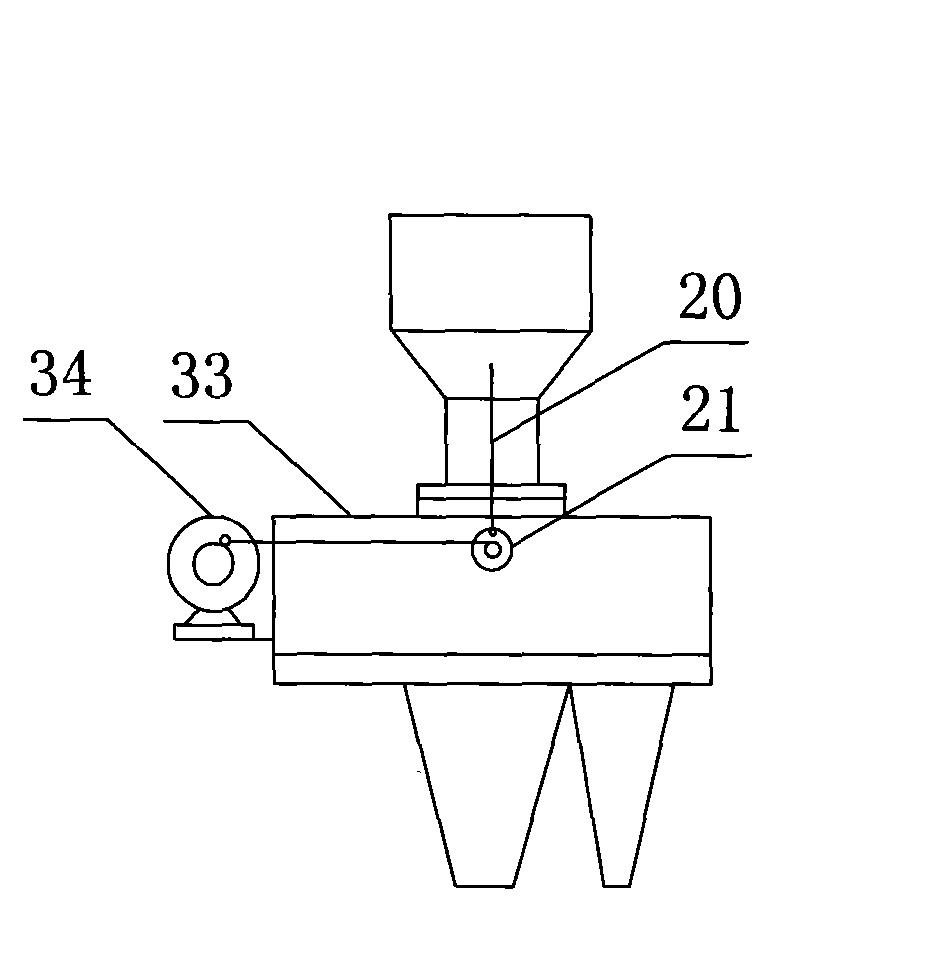

[0011] figure 1 The upper end of the vertical oxidation furnace body shown in is provided with an upper oxidation chamber 12, the middle part is provided with a middle oxidation chamber 14, the lower end is provided with a lower oxidation chamber 16, and the bottom of the upper oxidation chamber is provided with an upper group of heat collecting tubes 13, and the middle oxidation chamber The bottom of the bottom is provided with the middle group of heat collecting tubes 15, the bottom of the lower oxidation chamber is provided with the lower group of heat collecting tubes 17, the circumference of the upper, middle and lower three groups of heat collecting tubes are provided with cooling holes, and the upper ends of each group of heat collecting tubes are provided with Umbrella-shaped piercing cover 9, the piercing shield can prevent the raw materials falling from the feed hopper from entering the cooling hole, the left side of the furnace body is provided with a combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com