Discharge cooling device of red lead oxidation furnace

A technology of cooling device and oxidation furnace, which is applied in the direction of lead oxide, treatment of discharged materials, furnace, etc., can solve the problems of damage, increase of production cost, etc., and achieve the effect of increasing the contact area and increasing the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

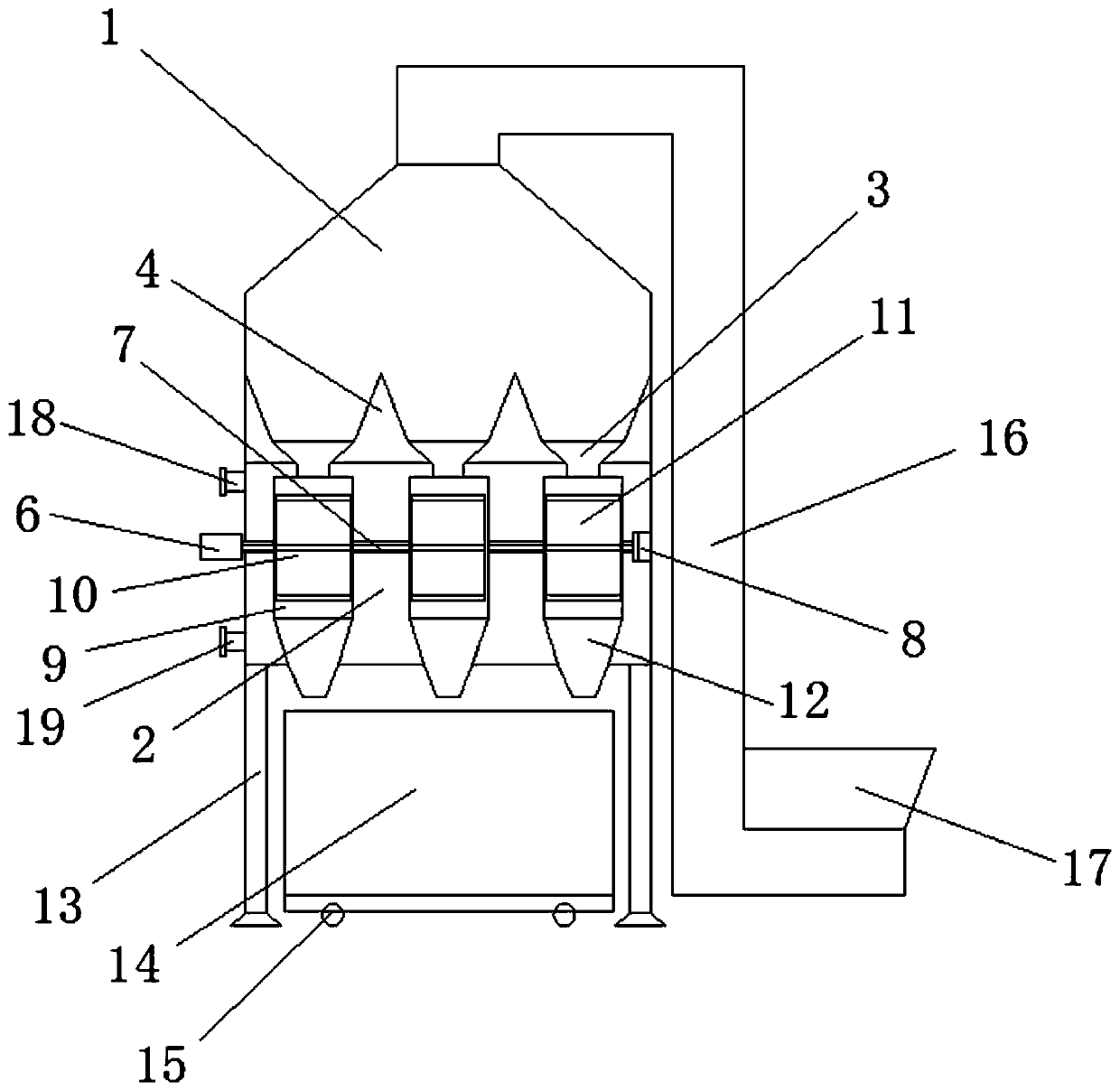

[0023] Embodiment 1: as Figure 1-4 As shown, a red lead oxidation furnace discharge cooling device includes a lower silo 1, a water chamber 2 storage box 14 and a hoist 16;

[0024] The lower silo 1 is located at the top of the water chamber 2, four groups of legs 13 are fixedly installed at the bottom of the water chamber 2, the storage box 14 is located at the bottom of the water chamber 2, and the top of the hoist 16 is in contact with the blanking chamber. The top of the warehouse 1 is connected, and the bottom of the hoist 16 is fixedly equipped with a feed hopper 17;

[0025] Lower hopper 1, three groups of hoppers 3 are fixedly installed on the bottom of the lower hopper 1, and guide plates 4 are fixedly connected to both sides of the hopper 3; the oxidized red lead raw material is placed in the feed hopper, and is lifted The machine lifts it to the top of the lower bin and falls, and the guide plates on both sides play a guiding role

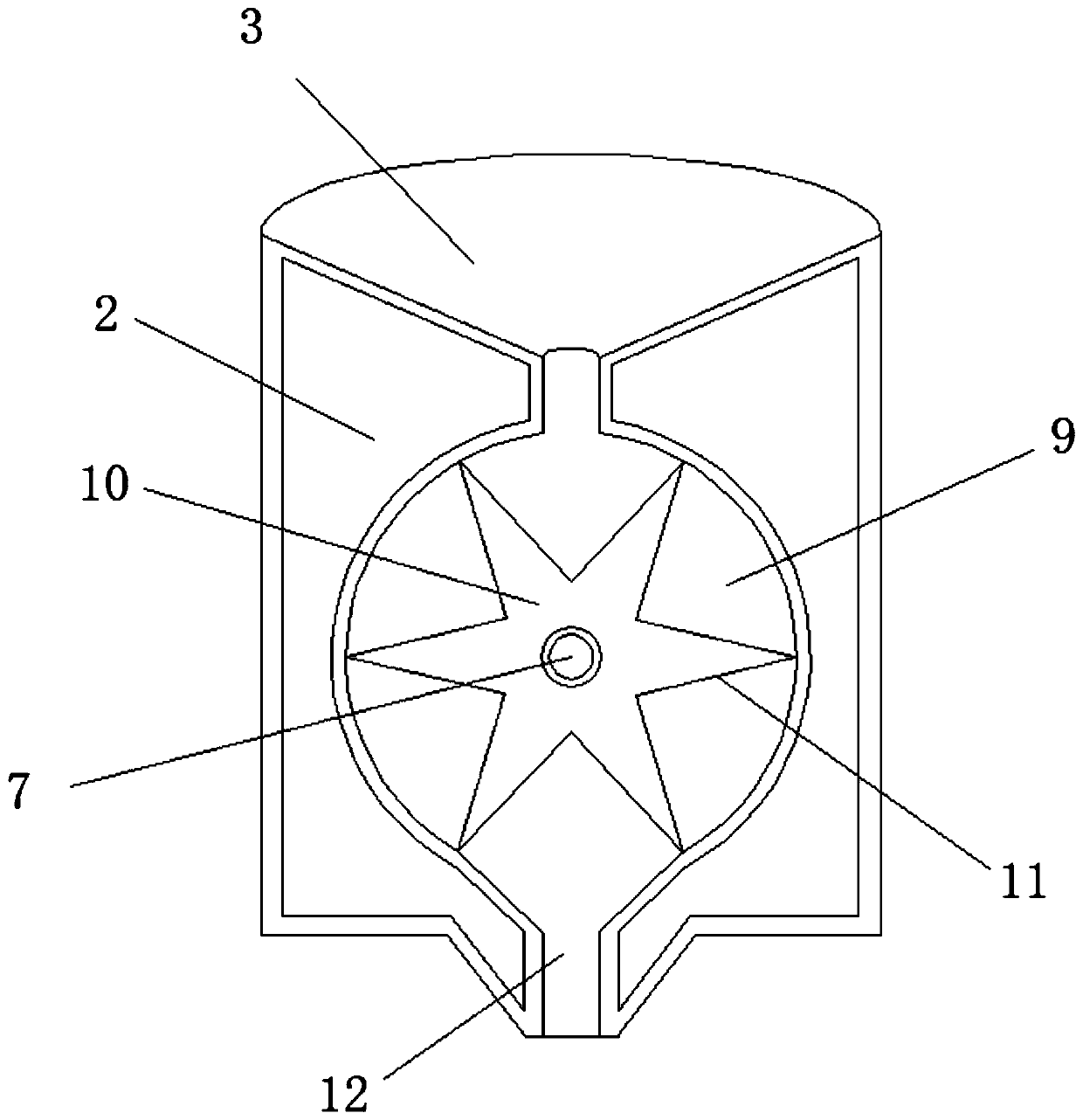

[0026] Water cavity 2, the inn...

Embodiment 2

[0031] Embodiment 2: as Figure 1-5 As shown, a red lead oxidation furnace discharge cooling device includes a lower silo 1, a water chamber 2 storage box 14 and a hoist 16;

[0032] The lower silo 1 is located at the top of the water chamber 2, four groups of legs 13 are fixedly installed at the bottom of the water chamber 2, the storage box 14 is located at the bottom of the water chamber 2, and the top of the hoist 16 is in contact with the blanking chamber. The top of the warehouse 1 is connected, and the bottom of the hoist 16 is fixedly equipped with a feed hopper 17;

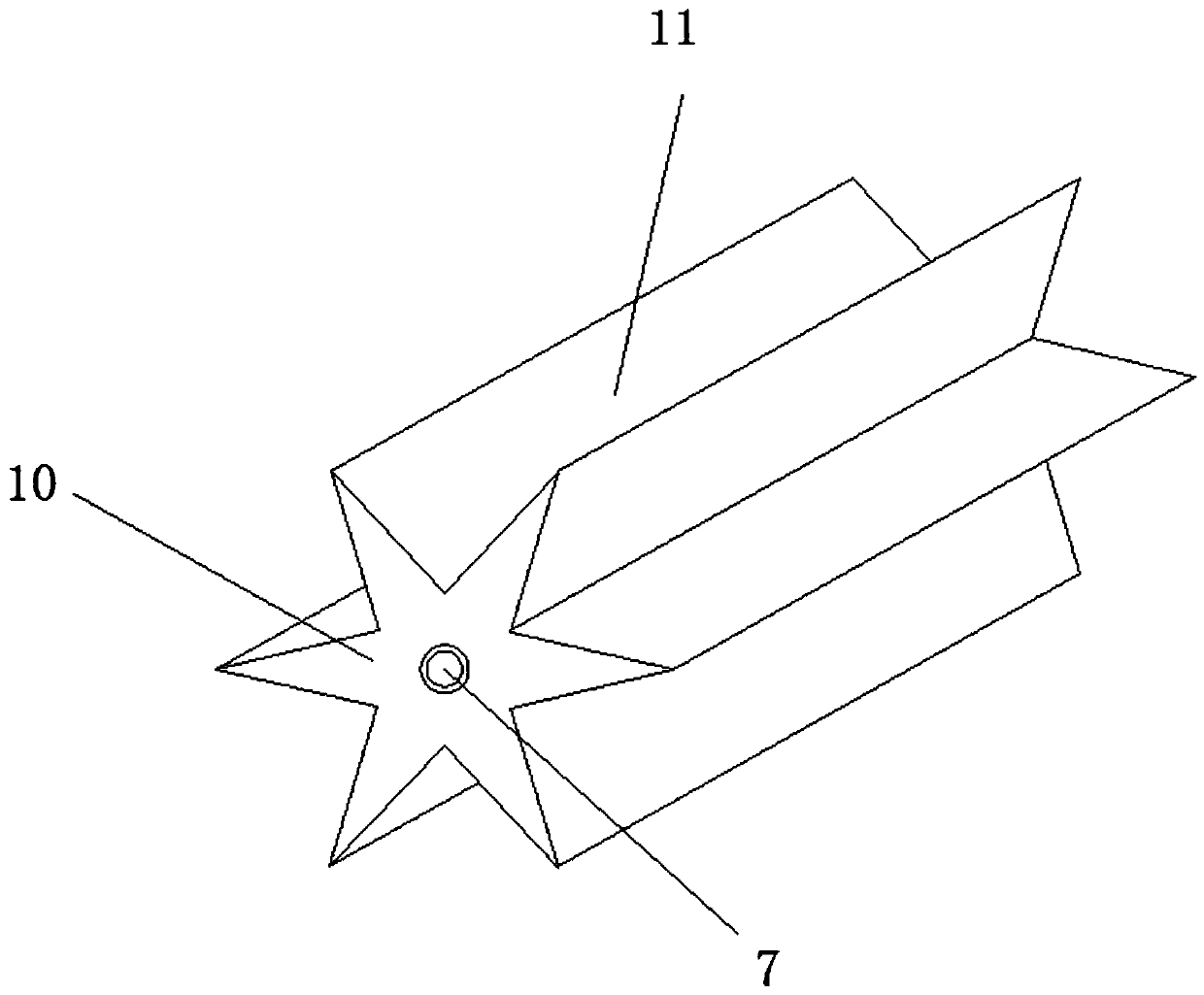

[0033] Lower silo 1, three groups of hoppers 3 are fixedly installed on the bottom of the lower hopper 1, guide plates 4 are fixedly connected to both sides of the hopper 3, and four groups of dispersed Plate 5: Put the oxidized red lead raw material in the feed hopper, lift it to the top of the lower silo and drop it by the elevator, and disperse the raw material during the falling process by the disper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com