Method for preparing red lead from positive electrode waste lead paste of lead-acid storage battery

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, battery electrodes, lead dan and other directions, can solve the problems of high cost, low cost, large pollution, etc., to solve the problem of waste, low energy consumption, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

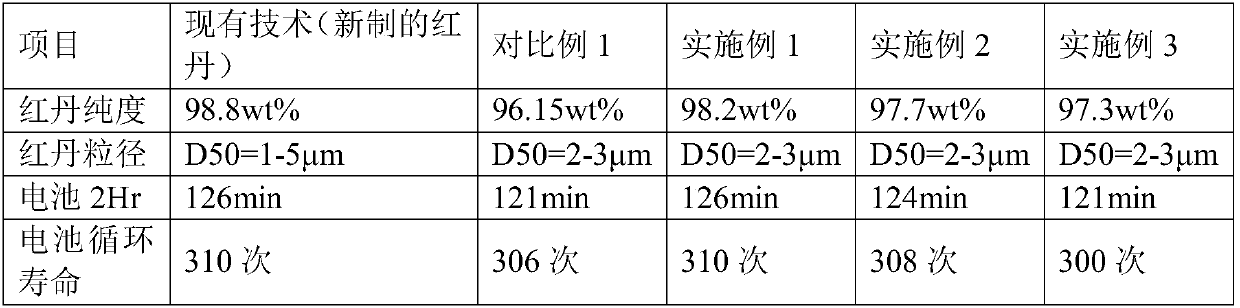

Examples

Embodiment 1

[0033] Pretreatment of positive electrode waste lead sludge: mix the positive electrode waste lead sludge of lead-acid battery with pure water at a mass ratio of 1:1, place in a stirring device and stir for 15 minutes, after standing for 20 minutes, remove the upper layer of liquid, and use a plate for the lower layer of material The solid-liquid separation of the frame filter press, the filtrate can be recycled, the filter cake is added to the mixed solution of ammonium sulfate and ammonia water at a mass ratio of 2:1, the temperature of the reaction vessel is raised to 60°C, and the filter cake and the mixed solution are stirred for 0.5 h, filter until no lead sulfate is leached to obtain ammonium sulfate mixed solution and pretreated positive electrode waste lead sludge.

[0034] Preparation of 4BS: Put the obtained ammonium sulfate mixture in a still, set the temperature of the still at 5°C after vacuum decompression, precipitate lead sulfate crystals, distill out ammonia w...

Embodiment 2

[0038] Pretreatment of positive electrode waste lead sludge: mix the positive electrode waste lead sludge of lead-acid battery with pure water at a mass ratio of 1:1.5, place in a stirring device and stir for 10 minutes, after standing for 15 minutes, remove the upper liquid, and use a plate for the lower material The frame filter press is used for solid-liquid separation, and the filtrate can be recycled. The filter cake is added to the mixture of ammonium sulfate and ammonia water at a mass ratio of 2:1.2. The temperature of the reaction vessel is raised to 40°C, and the filter cake and the mixed solution are stirred for 1 hour. , and filter until no lead sulfate is leached to obtain ammonium sulfate mixture and pretreated positive electrode waste lead sludge.

[0039] Preparation of 4BS: Put the obtained ammonium sulfate mixture in a still, set the temperature of the still at 10°C after vacuum decompression, and precipitate lead sulfate crystals. After distilling ammonia wat...

Embodiment 3

[0043] Pretreatment of positive electrode waste lead sludge: mix the positive electrode waste lead sludge of lead-acid battery with pure water at a mass ratio of 1:1.2, place in a stirring device and stir for 13 minutes, and after standing for 17 minutes, remove the upper layer of liquid, and use a plate for the lower layer of material The frame filter press is used for solid-liquid separation, and the filtrate can be recycled. The filter cake is added to the mixture of ammonium sulfate and ammonia water at a mass ratio of 2:1.1. The temperature of the reaction vessel is raised to 40°C, and the filter cake and the mixed solution are stirred for 1 hour. , and filter until no lead sulfate is leached to obtain ammonium sulfate mixture and pretreated positive electrode waste lead sludge.

[0044] Preparation of 4BS: Put the obtained ammonium sulfate mixture in a still, set the temperature of the still at 0°C after vacuum decompression, and precipitate lead sulfate crystals, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com