Method for producing nanometer lead oxide through clean transformation-microwave pyrolysis of lead sulfate paste

A lead sulfate and lead oxide technology, applied in the directions of lead monoxide, lead oxide, chemical instruments and methods, can solve the problems of environmental protection and green cleaning in the whole process without retrieval, and achieve direct productization, low thermal resistance, The effect of reducing exposure to high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

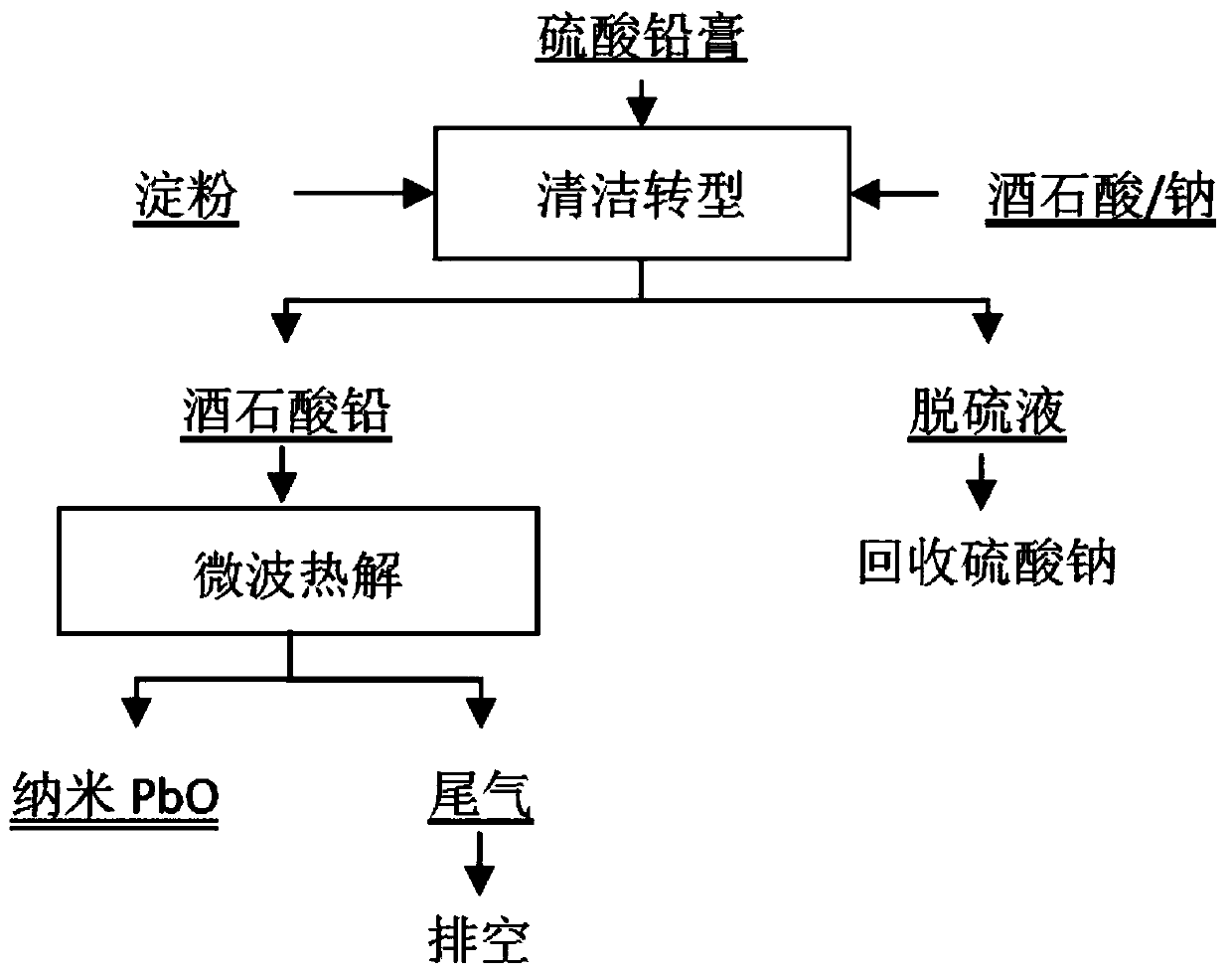

[0045] This embodiment provides a method for producing lead oxide nanometer by microwave pyrolysis, which is clean transformation of lead sulfate paste, and its process flow chart is as attached figure 1 As shown, it specifically includes the following steps:

[0046] S1. Solution transformation: Weigh 200g of lead sulfate paste, mix it evenly and finely grind it until the particle size is below -100 mesh. Add 1200mL transformation solution according to the liquid-solid ratio of 6:1, in which the concentration of tartrate group is 80g / L, and the molar concentration ratio of tartaric acid and sodium tartrate is 1:1. After raising the temperature to 50°C, add 4g of starch, keep warm and react for 2 hours, then filter and separate the eluate and insoluble matter to obtain eluate 1166mL, the dry weight of insoluble matter is 238.06g, the conversion rate of lead is calculated to be 97.38%, and the sulfur content in the solution is measured It is 9.48g / L, and the calculated desulfu...

Embodiment 2

[0049] This embodiment provides a method for producing lead oxide nanometer by microwave pyrolysis, which is clean transformation of lead sulfate paste, and its process flow chart is as attached figure 1 Shown, present embodiment is as the lead sulfate plaster of test raw material and auxiliary material with embodiment 1, specifically comprises the following steps:

[0050] S1. Solution transformation: Weigh 200g of lead sulfate paste, mix well and finely grind until the total particle size is below -150 mesh. Add 1000mL transformation solution according to the liquid-solid ratio of 5:1, in which the concentration of tartrate group is 80g / L, and the molar concentration ratio of tartaric acid and sodium tartrate is 1:1.5. After raising the temperature to 70°C, add 6g of starch, keep warm and react for 1h, then filter and separate the eluate and insoluble matter to obtain eluate 952mL, the dry weight of insoluble matter is 241.56g, the conversion rate of lead is calculated to be...

Embodiment 3

[0053] This embodiment provides a method for producing lead oxide nanometer by microwave pyrolysis, which is clean transformation of lead sulfate paste, and its process flow chart is as attached figure 1 Shown, present embodiment is as the lead sulfate plaster of test raw material and auxiliary material with embodiment 1, specifically comprises the following steps:

[0054] S1. Solution transformation: Weigh 500g of lead sulfate paste, mix it evenly and finely grind it until the particle size is below -200 mesh. Add 2000mL transformation solution according to the liquid-solid ratio of 4:1, in which the concentration of tartrate group is 80g / L, the ratio of molar concentration of tartaric acid to sodium tartrate is 1:1.5, after heating up to 50°C, add 10g of starch, keep warm and react for 4h, then filter Separate eluate and insoluble matter to obtain eluate 1947mL, dry weight of insoluble matter 601.64g, the calculated lead conversion rate is 98.63%, the sulfur content in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com