Synthesis method of alpha-PbO

A synthesis method and surfactant technology, applied in the directions of lead monoxide, lead oxide, etc., can solve the problems of complex operation, difficult control and difficulty of solvothermal method, and achieve large-scale production, mild reaction conditions and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix 20g of lead nitrate, 18g of urea and 0.5g of SDBS into the container, add 500g of double-distilled water into the container, and then continue to react in an oil bath at 85°C for 4 hours, and keep stirring during the reaction.

[0023] (2) The material obtained by the reaction was suction-filtered, washed three times with double distilled water and ethanol, and dried in a drying oven at 80° C. to obtain the precursor of α-PbO, that is, lead carbonate.

[0024] (3) Calcining the α-PbO precursor obtained in step (2) at 300° C. for 3 hours to obtain α-PbO.

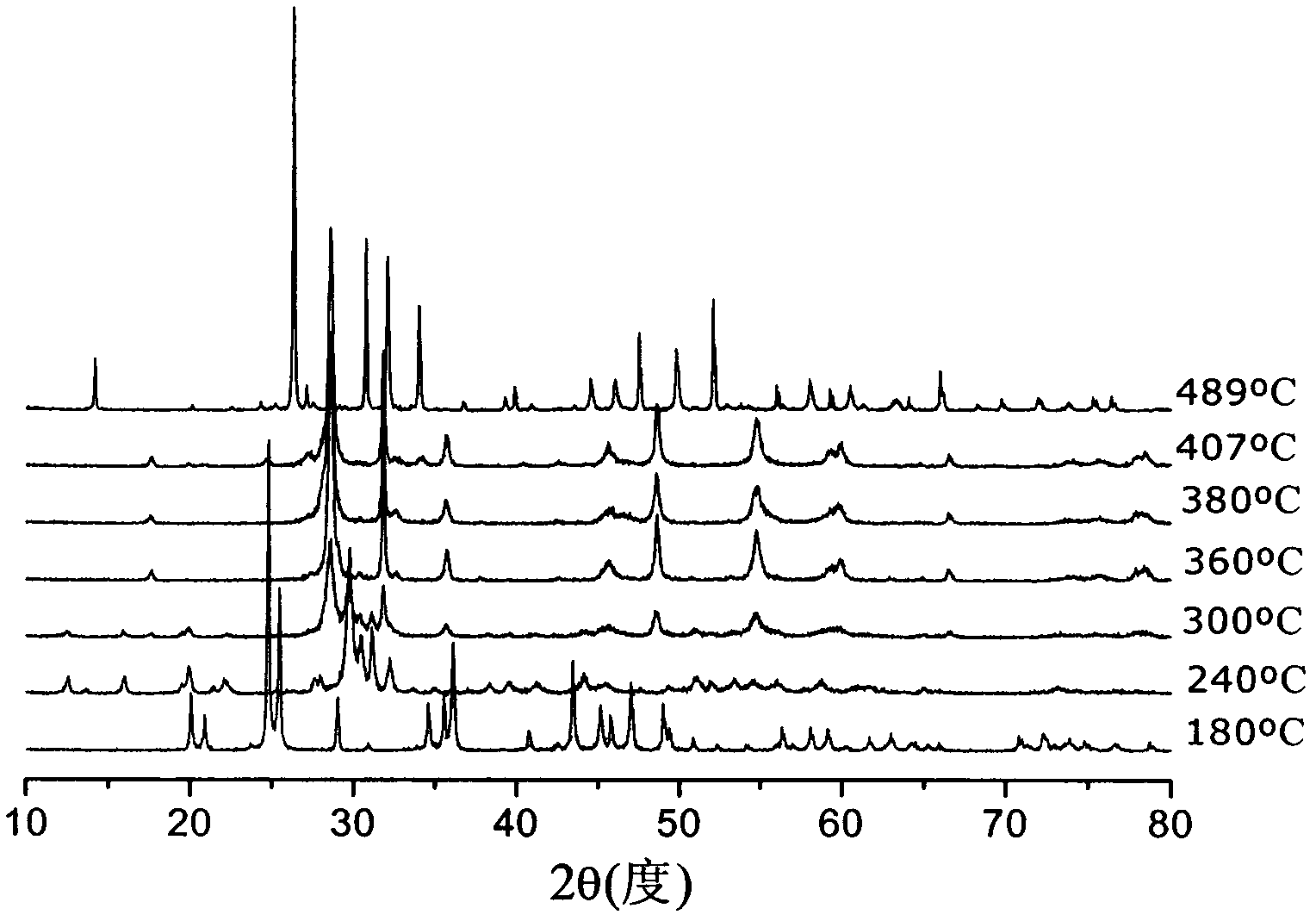

[0025] The XRD powder diffraction characterization of gained sample, see appendix figure 1 .

Embodiment 2

[0027] The difference from Example 1 is that the calcination temperature of the α-PbO precursor obtained in step (3) is 360° C. to obtain α-PbO, and the other conditions are completely the same.

[0028] The XRD powder diffraction characterization of gained sample, see appendix figure 1 .

Embodiment 3

[0030] The difference from Example 1 is that the calcination temperature of the α-PbO precursor obtained in step (3) is 380° C. to obtain α-PbO, and the other conditions are completely the same.

[0031] The XRD powder diffraction characterization of gained sample, see appendix figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com