Drying method of raw material blank in continuous production of vanadium nitride and its device

A technology of production process and drying method, which is applied in the direction of chemical instruments and methods, lead oxide, vanadium compounds, etc., can solve the problems of high water content in the raw material billet and the impact on the service life of the main sintering furnace, so as to simplify the equipment and reduce the number of furnace material reloading , Improve the effect of vanadium recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

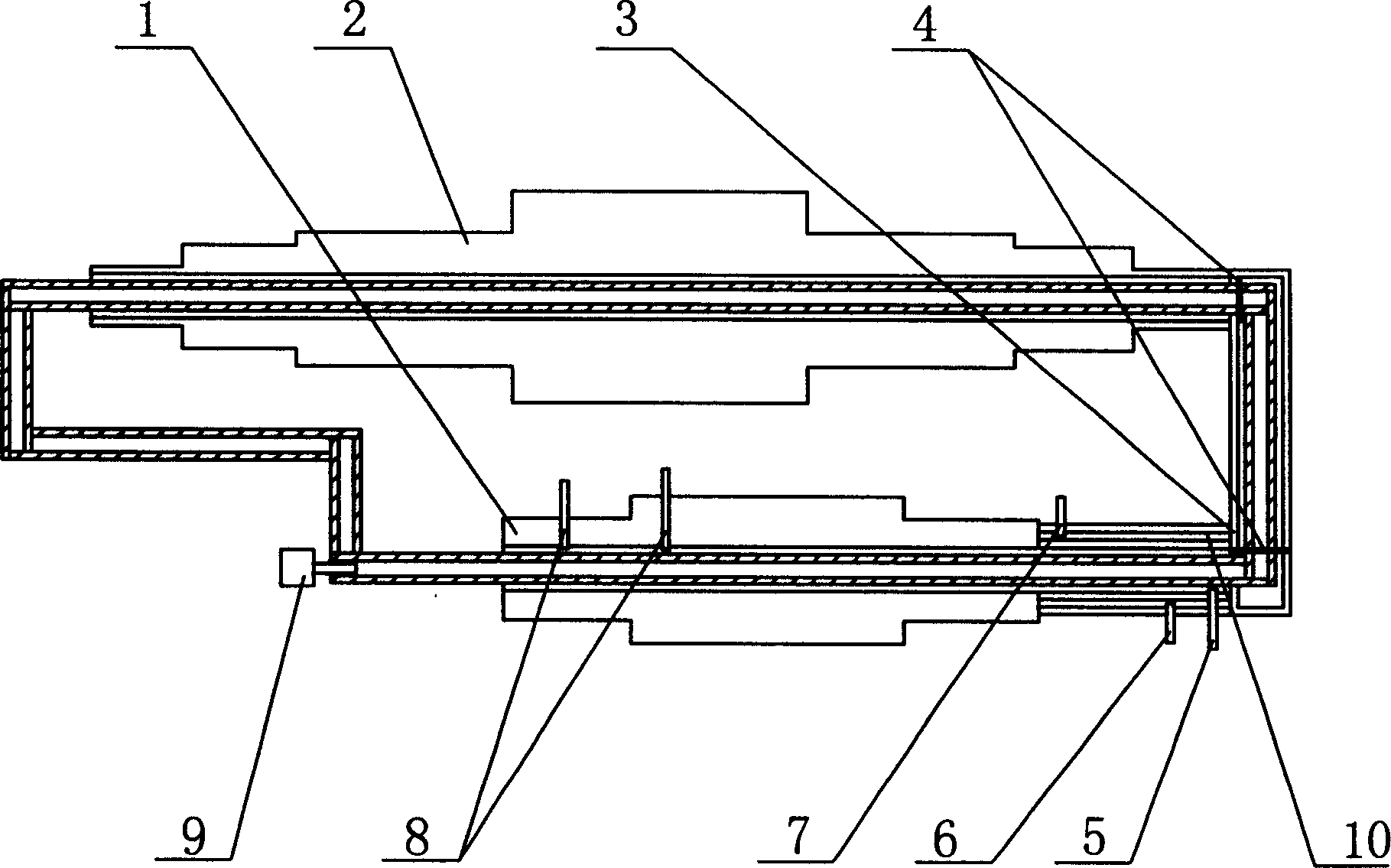

[0016] Embodiment 1: The drying method and device for the raw material billet in the continuous production process of vanadium nitride of the present invention is that the auxiliary electric heating furnace 1 is arranged in parallel on the side of the main sintering furnace 2, and the auxiliary electric heating furnace 1 is arranged between the main sintering furnace 2 There is a fully enclosed sealed channel 3 to communicate with each other, the center line of the auxiliary electric furnace 1 coincides with the automatic return center line of the main sintering furnace 2, and the main push cylinder of the auxiliary electric furnace 1 uses the return push cylinder 9 of the main sintering furnace 2, Two sealed gates 4 are arranged between the auxiliary electric heating furnace 1 and the main sintering furnace 2 to block the gas flow between the auxiliary electric heating furnace 1 and the main sintering furnace 2 . The gas inlet 5 is arranged at the outlet end of the auxiliary e...

Embodiment 2

[0018] Embodiment 2: The method and device for drying raw material blanks in the continuous production process of vanadium nitride of the present invention is to arrange an auxiliary electric heating furnace 1 in parallel on the side of the main sintering furnace 2, and arrange between the auxiliary electric heating furnace 1 and the main sintering furnace 2 There is a fully enclosed sealed channel 3 to communicate with each other, the center line of the auxiliary electric furnace 1 coincides with the automatic return center line of the main sintering furnace 2, and the main push cylinder of the auxiliary electric furnace 1 uses the return push cylinder 9 of the main sintering furnace 2, Two sealed gates 4 are arranged between the auxiliary electric heating furnace 1 and the main sintering furnace 2 to block the gas flow between the auxiliary electric heating furnace 1 and the main sintering furnace 2 . The gas inlet 5 is arranged at the outlet end of the auxiliary electric fur...

Embodiment 3

[0020]Embodiment 3: The method and device for drying raw material blanks in the continuous production process of vanadium nitride of the present invention is to arrange an auxiliary electric heating furnace 1 in parallel on the side of the main sintering furnace 2, and arrange between the auxiliary electric heating furnace 1 and the main sintering furnace 2 There is a fully enclosed sealed channel 3 to connect them with each other, the center line of the auxiliary electric furnace 1 coincides with the automatic return center line of the main sintering furnace 2, and the main push cylinder of the auxiliary electric furnace 1 uses the return push cylinder 9 of the main sintering furnace 2, Two sealed gates 4 are arranged between the auxiliary electric heating furnace 1 and the main sintering furnace 2 to block the gas flow between the auxiliary electric heating furnace 1 and the main sintering furnace 2 . The gas inlet 5 is arranged at the outlet end of the auxiliary electric fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com