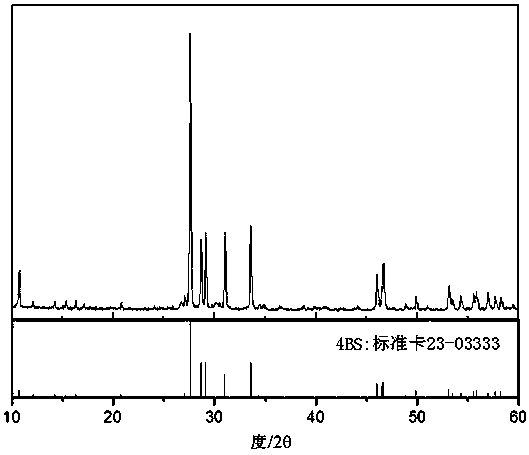

High-performance battery small-crystal-size 4BS additive preparation method

A technology of additive preparation and crystal size, applied in battery electrodes, lead-acid batteries, circuits, etc., can solve the problems of 4BS crystal size, difficult to control purity, difficult to realize industrial production, complex preparation process, etc., to achieve high product application value, Simple and easy operation, the effect of improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

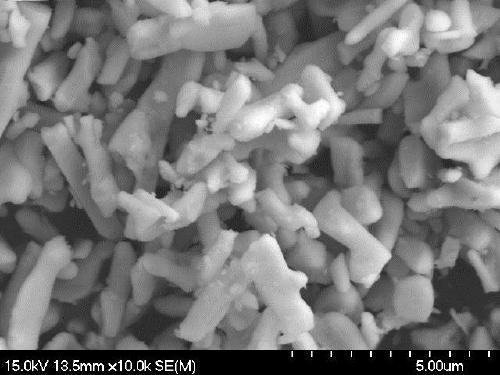

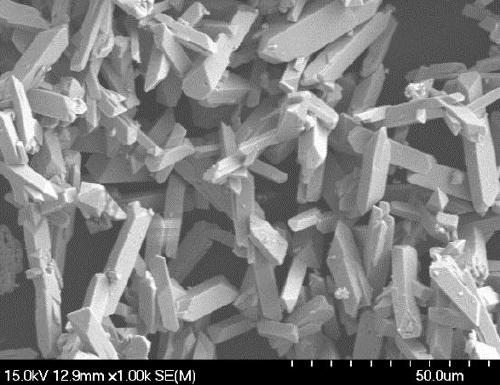

Embodiment 1

[0036] Using β-PbO and sulfuric acid aqueous solution as reactants, the amount of reactants is proportioned according to the molar ratio of the total lead element to the sulfate radical in the two raw materials of 5:1.

[0037] Step 1: Add 40 g of β-PbO to 100 mL of water, and then add the sulfuric acid aqueous solution in the first and second stages. The first stage is to add 11.48 mL of a sulfuric acid aqueous solution with a concentration of 2.5 mol / L within 6 minutes, and under the conditions of an ultrasonic power of 800 W and an ultrasonic frequency of 40 kHz, the temperature is controlled at 60-80° C., and the ultrasonic for 90 minutes; The second stage is to add 2.87ml, 2.5mol / L sulfuric acid aqueous solution and 0.05% fumed silica of the total mass of the reaction system within 12 minutes, and ultrasonicate for 30 minutes under the conditions of ultrasonic power of 400W and ultrasonic frequency of 60kHz , The temperature is controlled at 20-40℃; a suspension is obtained;...

Embodiment 2

[0041] Using β-PbO and lead sulfate as reactants, the amount of reactants is proportioned according to the molar ratio of total lead element to sulfate radical in the two raw materials of 5:1, and the total amount of lead element in the two raw materials is the same as the embodiment 1. That is, the raw materials are 32 g β-PbO and 10.88 g lead sulfate. The rest of the steps and processes are the same as in Example 1. The solid powder is tested by XRD and the 4BS content is 98.0%. The SEM test shows that the crystal length size is less than 5 μm.

Embodiment 3

[0043] Using β-PbO and tribasic lead sulfate as reactants, the amount of reactants is proportioned according to the molar ratio of total lead element to sulfate radical in the two raw materials of 5:1, and the total amount of lead element in the two raw materials The same as in Example 1. That is, the raw materials are 32 g β-PbO and 34.9 g tribasic lead sulfate. The remaining steps and processes are the same as in Example 1. The 4BS content in the solid powder is 99.0%, and the SEM test shows that the crystal length size is less than 5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com