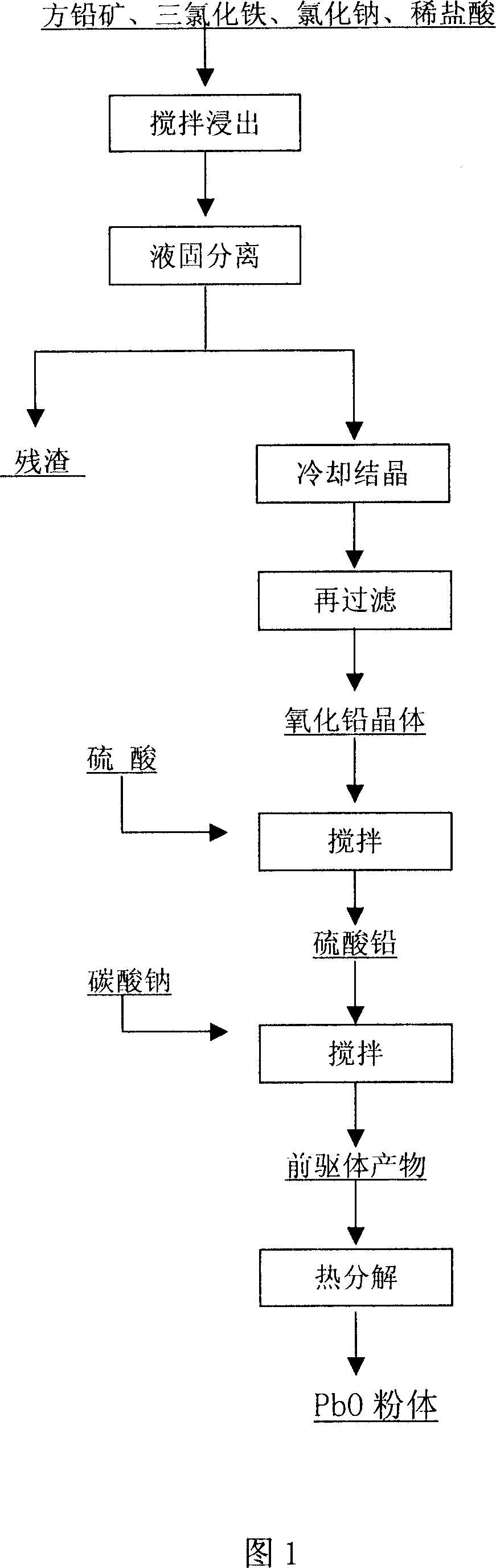

Method of directly producing ultra-fine lead oxide powder from galena concentrate

The technology of galena and concentrate is applied in the field of preparing ultrafine lead oxide powder, which can solve the problems of easy damage of crystal lattice, environmental pollution and high energy consumption, and achieves the reduction of the content of impurity elements, the reduction of production costs, and the expansion of raw materials. effect of source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] 1. The galena concentrate of a lead-zinc mine is used, and the -0.074mm particle size accounts for 85%. The chemical composition is shown in Table 1.

[0040] Pb

Fe

Zn

Cu

C

S

CaO

MgO

SiO 2

58.80

12.52

0.41

0.037

0.57

25.04

0.068

0.038

1.64

[0041] The leaching process conditions are: the leaching solid-liquid ratio is 1 / 4, the pH of the solution is adjusted to 1.20 with hydrochloric acid, the reaction time is 40 minutes, and the reaction temperature is 85°C; the leaching agent FeCl 3 ·6H 2 The amount of O used is 350g / L, and the amount of NaCl is 100g / L. The lead leaching rate can reach 97.39%, and the leaching product lead chloride (PbCl 2 ) purity is shown in Table 2.

[0042] name

W(Cu) / %

W(Fe) / %

W(Zn) / %

W(Ca) / %

PbCl 2

0.0002

0.0035

0.0009

0.0150

[0043] Leaching products from galena conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com