Method for recovering lead oxide from waste lead plaster

一种氧化铅、铅膏的技术,应用在一氧化铅、氧化铅、废物收集者回收等方向,能够解决除杂效果差、重结晶次数多等问题,达到工艺过程环保、原子经济性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

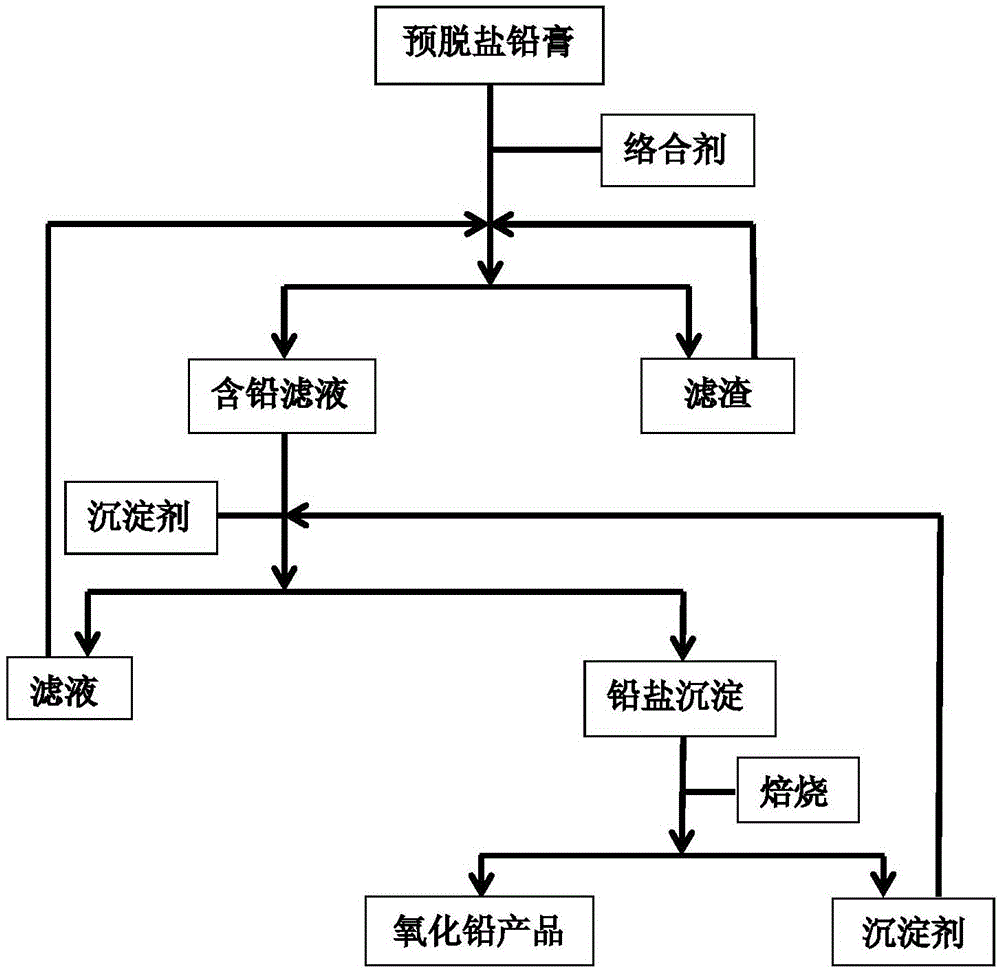

Image

Examples

Embodiment 1

[0079] Take commercially available waste valve-regulated sealed lead-acid batteries with specifications of 12V and 7Ah and crush and separate them by conventional methods to obtain lead paste. After obtaining the total amount of lead sulfate in the lead paste through traditional chemical titration analysis, then add stoichiometric 10% NaOH as lye, control the treatment temperature at 35°C, the treatment time is 10min, and the stirring speed is 100 rpm. After the lead plaster is treated with lye, the solid-liquid separation is carried out to obtain the pre-desalted lead paste and the desalted mother liquor mainly composed of sodium sulfate. The process is as follows:

[0080] a. Add 1 kg of the pre-desalted lead paste into the 10L first reactor, add 0.6 kg of lead powder obtained by conventional crushing of excessive lead-containing grids to the reactor, 8 g of cobalt oxide as a catalyst, and a sufficient amount of 0.5 mol / L arginine aqueous solution was used as a complexing a...

Embodiment 2

[0085]Use 12% KOH solution instead of the pre-desalted lye, and the desalination treatment temperature is 40°C. In the step a, the complexing agent is changed to 0.75mol / L ethylenediamine aqueous solution, and the catalyst is changed to copper oxide 13g, and in the step b, the CO 2 change to SO 2 , the rest are consistent with Example 1, the PbO purity finally obtained is 99.97%, and the comprehensive recovery rate of lead is 99.6%.

Embodiment 3

[0087] In the step a, the complexing agent is changed to 1mol / L ethylenediamine diacetic acid aqueous solution, and the catalyst is changed to silver nitrate 5g, and in the step b, the CO 2 change to SO 3 , the rest are consistent with Example 1, the PbO purity finally obtained is 99.96%, and the comprehensive recovery rate of lead is 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com