High manganese and low chromium type high strength and toughness hot-work die steel and preparation method thereof

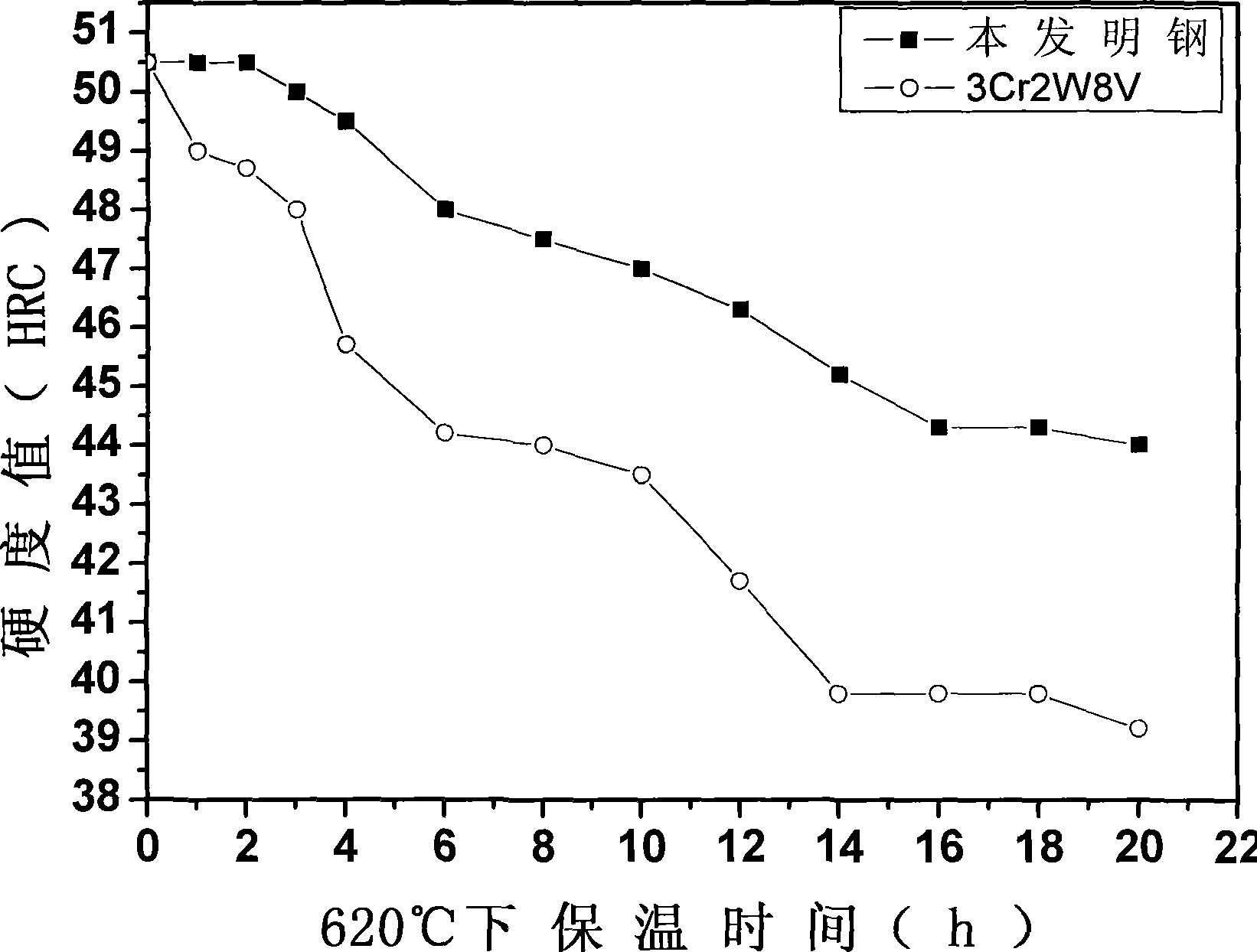

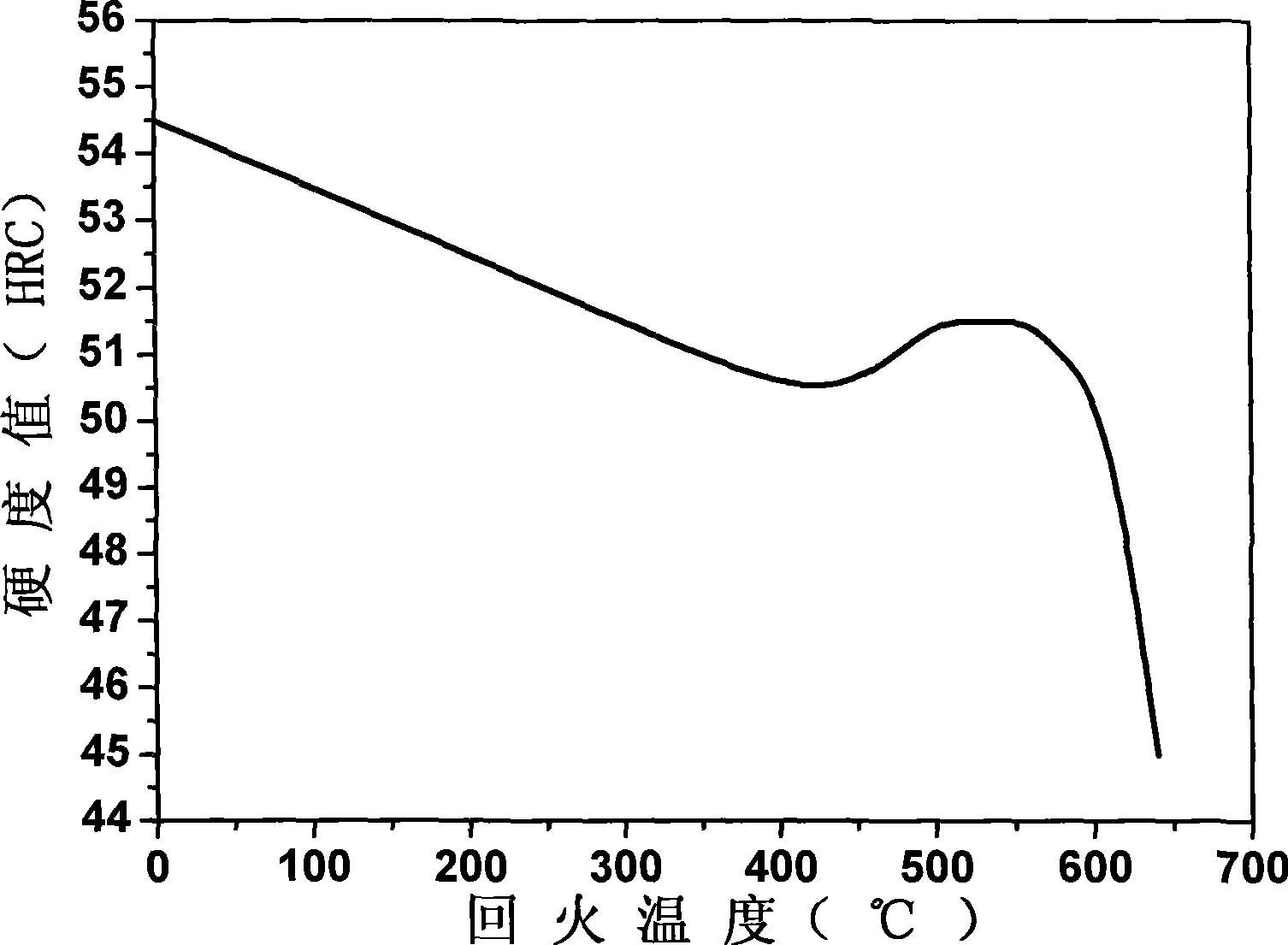

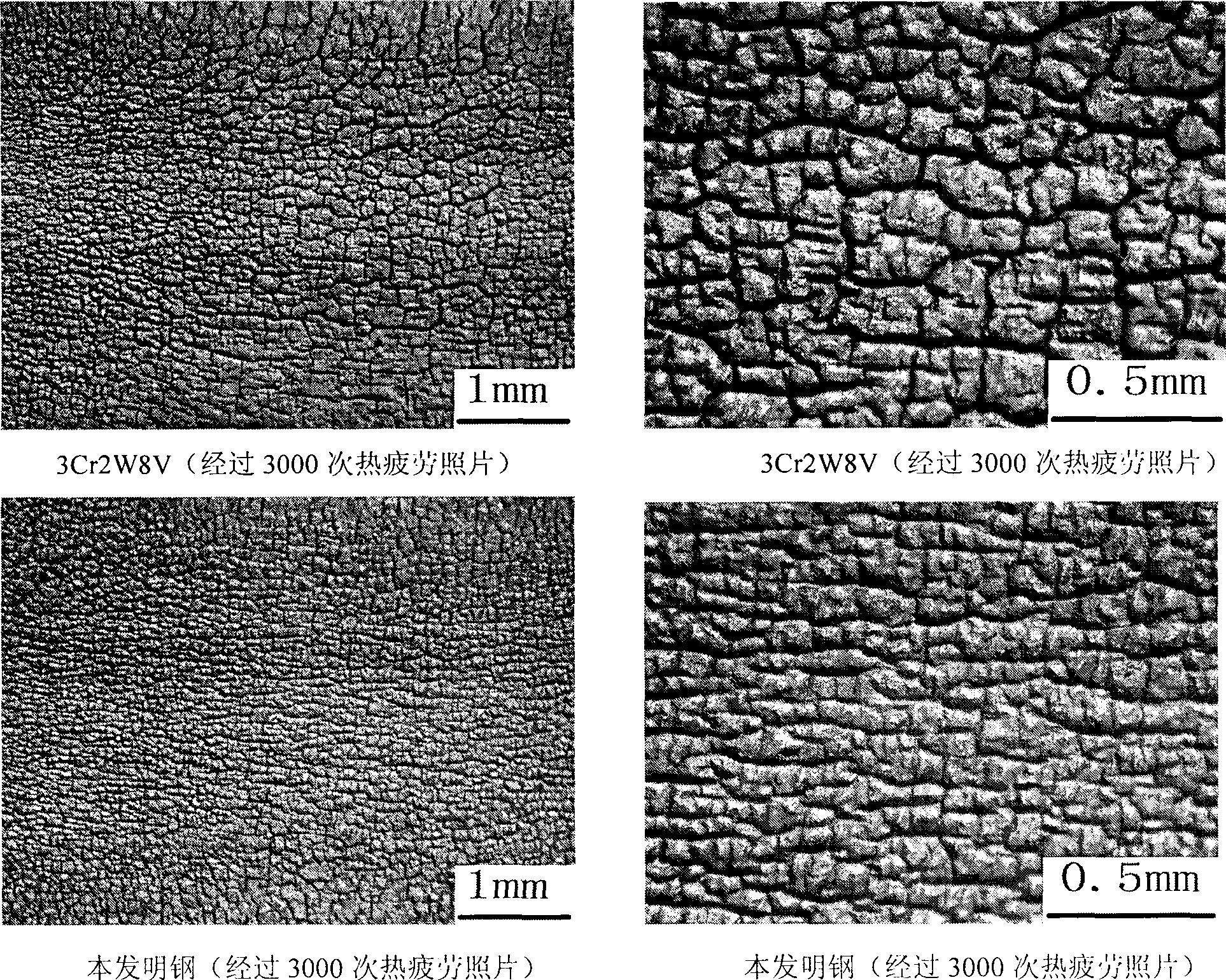

A hot work die steel, high strength and toughness technology, applied in the field of alloy steel manufacturing process, can solve the problems of low thermal strength, plastic toughness, poor thermal fatigue performance of thermal conductivity, collapse of the working part of the mold, etc., to achieve high thermal stability, Effect of Good Impact Toughness and Thermal Fatigue Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, the composition and weight percentage of the hot work die steel are as follows:

[0029] C 0.41%, Si 0.33%, Mn 0.99%, Cr 2.36%, Mo 1.61%,

[0030] V 1.02%, W 1.53%, P 0.01%, S 0.01%, Fe balance.

[0031] In the present embodiment, the technical process and steps of hot work die steel are as follows:

[0032] a. Induction smelting: smelting in an induction furnace according to the above-mentioned ratio of alloying elements, and the melting temperature is greater than 1500

[0033] ℃, then cast into Φ80mm steel ingot and air-cooled;

[0034] b. Electroslag remelting: the poured steel ingot is placed in the electroslag remelting device as a consumable electrode for electroslag remelting, and the liquid metal falls through the slag layer of the slag pool to the water-cooled crystallizer below. re-solidified into steel ingots;

[0035] c. High-temperature homogenization: heat the steel ingot after electroslag remelting to 1250°C for high-temperature homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com