Machine for automatically processing bearing outer ring

A bearing outer ring, automatic processing technology, applied in the field of bearing processing, can solve the problems of low processing efficiency and low degree of automation, and achieve the effects of reducing impact force, improving comprehensive cutting performance, and strong competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

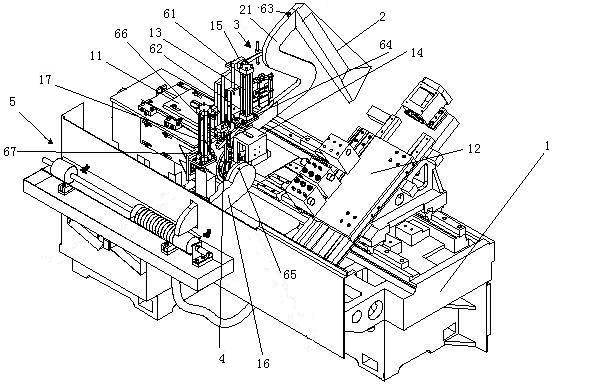

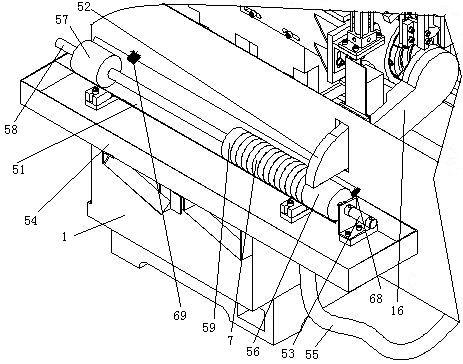

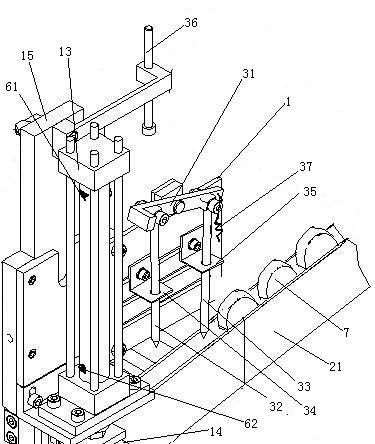

[0026] see figure 1 , an automatic processing machine for bearing outer rings, comprising a frame 1 and an automatic hoist 2, the frame 1 is provided with a case 11, and the case 11 is provided with a main shaft 8 and a main motor for driving the main shaft. figure 1 The main shaft 8 and the main motor are not drawn, the main shaft 8 extends along the left and right directions, the structure of the main shaft 8 is shown in Image 6 , the right end of the cabinet 11 is provided with a collet mechanism 4 driven by the main shaft to rotate, and the frame 1 is provided with a tool holder 12 for fixing the cutting tool that can move axially along the main shaft, that is, move left and right. 11 is also provided with feeding oil cylinder 13, and feeding oil cylinder shrinkage detection switch 61 and feeding oil cylinder stretch out detection switch 62 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com