Phase change cold storage material with double phase change points and preparation method thereof

A phase-change cold storage and dual-phase change technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of serious energy consumption, increased transportation costs, and spoilage of goods, and achieves efficient and fast cooling effect and phase change. The effect of high latent heat enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A phase change thermal storage material with multiple phase transition points, prepared using the following quality material-level steps: 30g xylitol, 20g potassium chloride, 43g deionized water, 1.8g spar, 3g carboxymethyl cellulose, borax 2.2g. First, dissolve sodium chloride in deionized water to form a sodium chloride salt solution, then add xylitol, stir quickly until completely dissolved, then add Span and carboxymethyl cellulose, and stir rapidly at a stirring speed of 800r / min To a viscous state, finally add borax, stir for 1 hour and then take a sample to measure DSC.

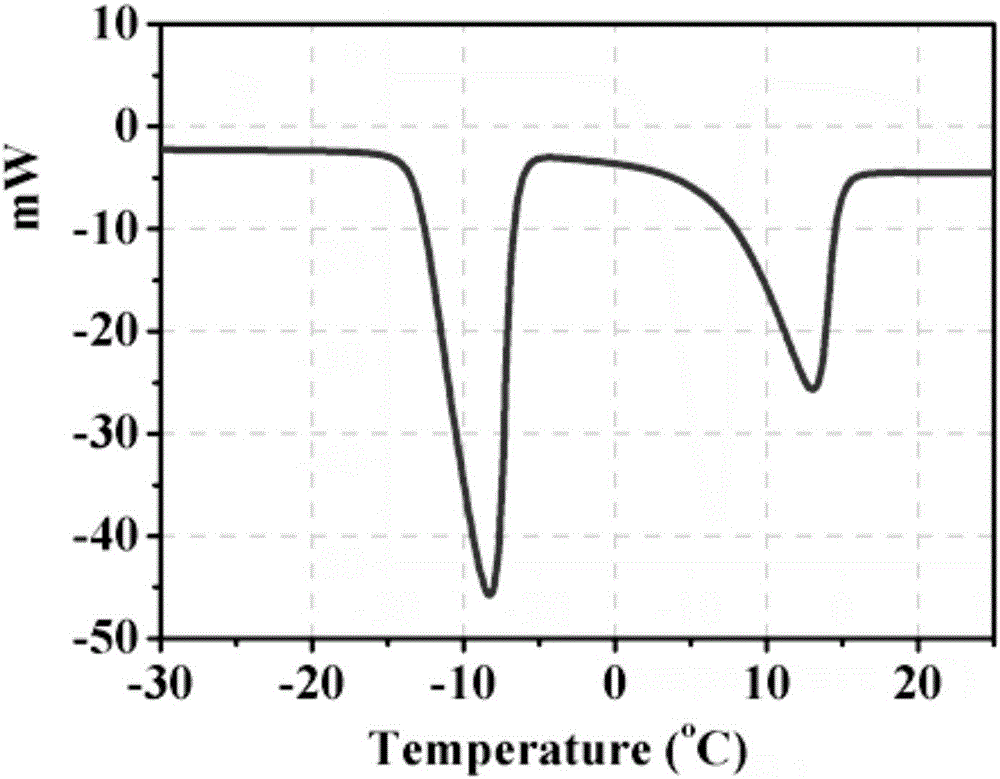

[0025] Use differential calorimetry scanner (DSC) to test its phase transition temperature, get as follows figure 1 A phase change material with two phase change temperature points, the peak temperatures of the two phase change temperature points are 13°C and -10°C respectively, and the overall latent heat of phase change is 225kJ / kg, which can be effectively applied to the whole process of foo...

Embodiment 2

[0027] A phase change thermal storage material with multiple phase transition points is prepared using the following high-quality material-level steps: 28 g of sorbitol, 67 g of deionized water, 0.8 g of fatty alcohol polyoxyethylene ether, 2 g of gelatin, and 2.2 g of copper sulfide. First, add sorbitol into deionized water and stir quickly to melt completely to form an organic solution, then add fatty alcohol polyoxyethylene ether and gelatin, stir quickly at a stirring speed of 800r / min until viscous, finally add copper sulfide, and stir for 1 hour Afterwards, samples were taken to determine DSC.

[0028] Use the differential calorimetry scanner (DSC) to test its phase transition temperature, and obtain a phase change material with two phase transition temperature points. The peak temperatures of the two phase transition temperature points are 10°C and -1°C respectively. The overall phase transition The latent heat is 230kJ / kg, which can effectively control the temperature ...

Embodiment 3

[0030] A phase change thermal storage material with multiple phase transition points, prepared using the following quality material-level steps: erythritol 40g, sodium chloride 20g, deionized water 35g, sodium lauryl sulfate 1.2g, fumed silica 2g , calcium oxide 1.8g. First, dissolve 20g of potassium chloride in deionized water to form a potassium chloride salt solution, then add erythritol, stir rapidly until it is completely dissolved, then add fumed silica and sodium lauric acid sulfate, at 800r / min Stir rapidly at the stirring speed until it becomes viscous, finally add calcium oxide, and take a sample to measure DSC after stirring for 1 hour.

[0031] Use the differential calorimetry scanner (DSC) to test its phase transition temperature, and obtain a phase change material with two phase transition temperature points. The peak temperatures of the two phase transition temperature points are 20°C and -20°C respectively. The overall phase transition The latent heat is 230kJ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com