PC component production line

A production line and component technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve the problems of large production site occupied by arranging molds, low mold reuse rate, and increased production costs, so as to improve maintenance efficiency, The production environment is good and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

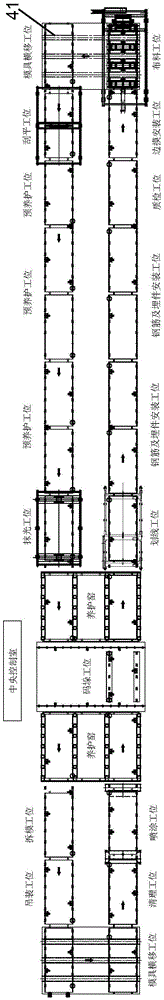

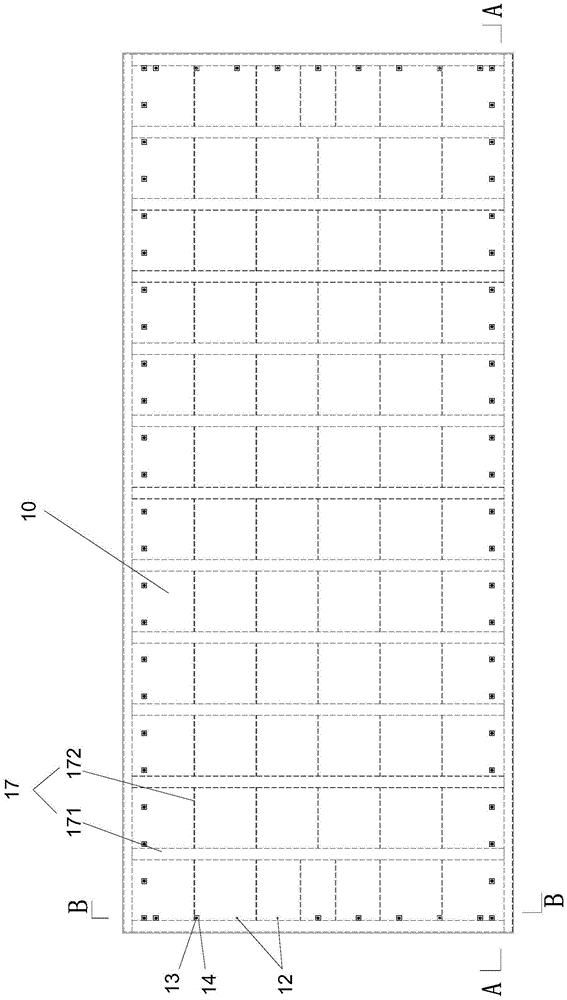

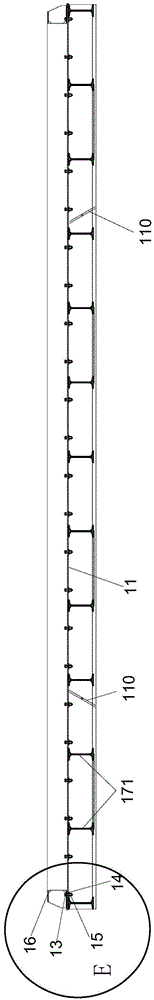

[0055] figure 1It is a schematic diagram of the overall layout of the production line of the present invention. As shown in the figure, the PC component production line disclosed by the present invention includes a cleaning station connected by a conveying track, a spraying station, a marking station, a steel bar and embedded parts installation station, a quality Inspection station, side mold installation station, cloth station, mold traverse station, scraping station, pre-maintenance station, troweling station, curing kiln, palletizing station, demoulding station, hoisting station Position, etc., driven by the conveying track, the mold components walk in the order of the above stations, and after the process of each station, various models and specifications of PC components with specific sizes and shapes can be produced.

[0056] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com