Fully automatic hydroform and intelligent stacking device for bricks

A hydraulic forming and fully automatic technology, applied in the direction of supply device, unloading device, ceramic molding machine, etc., can solve the problems of complex structure of mechanical equipment, low production efficiency, lengthy production line, etc., to reduce multiple handling links and improve production Efficiency and the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

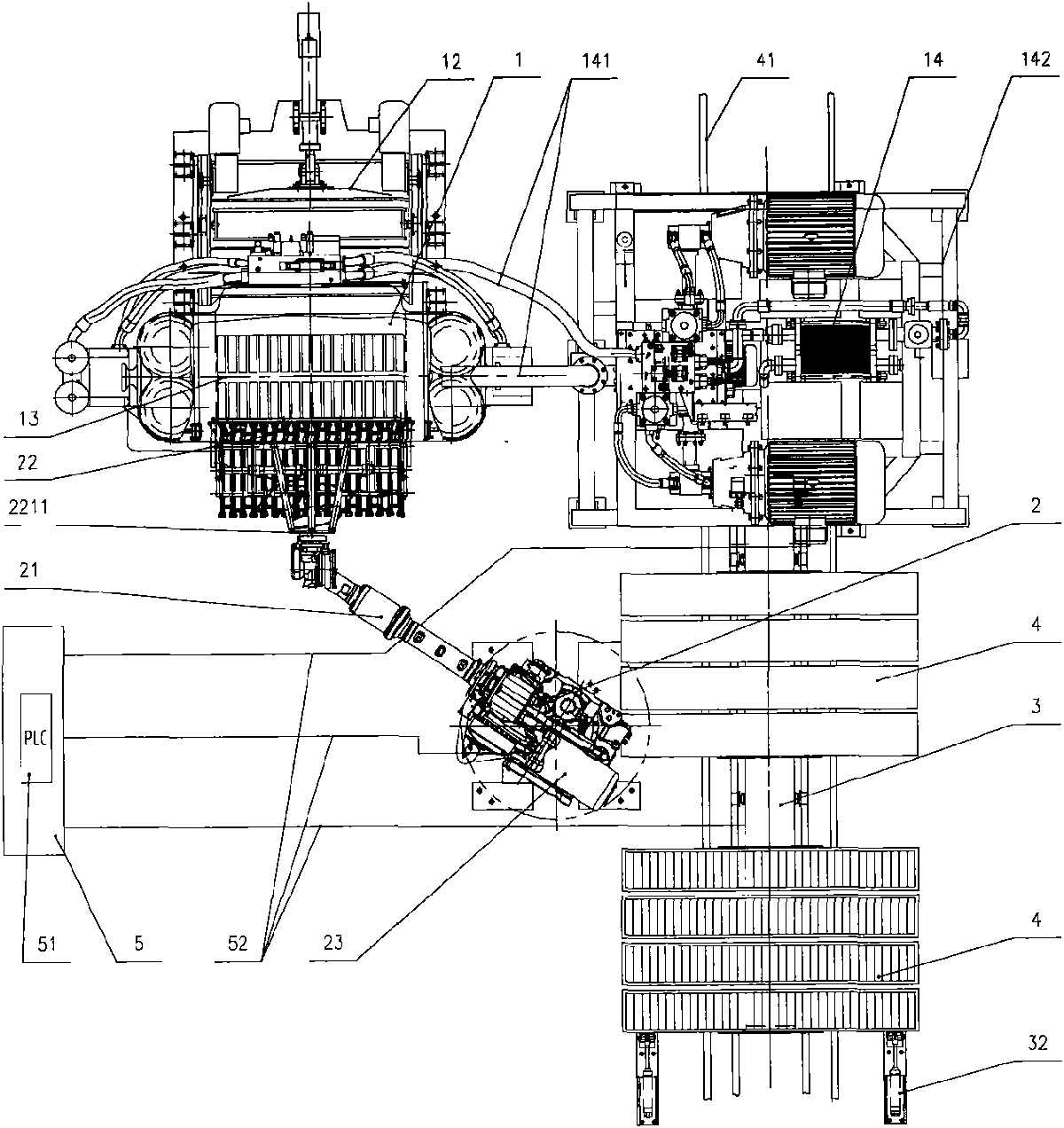

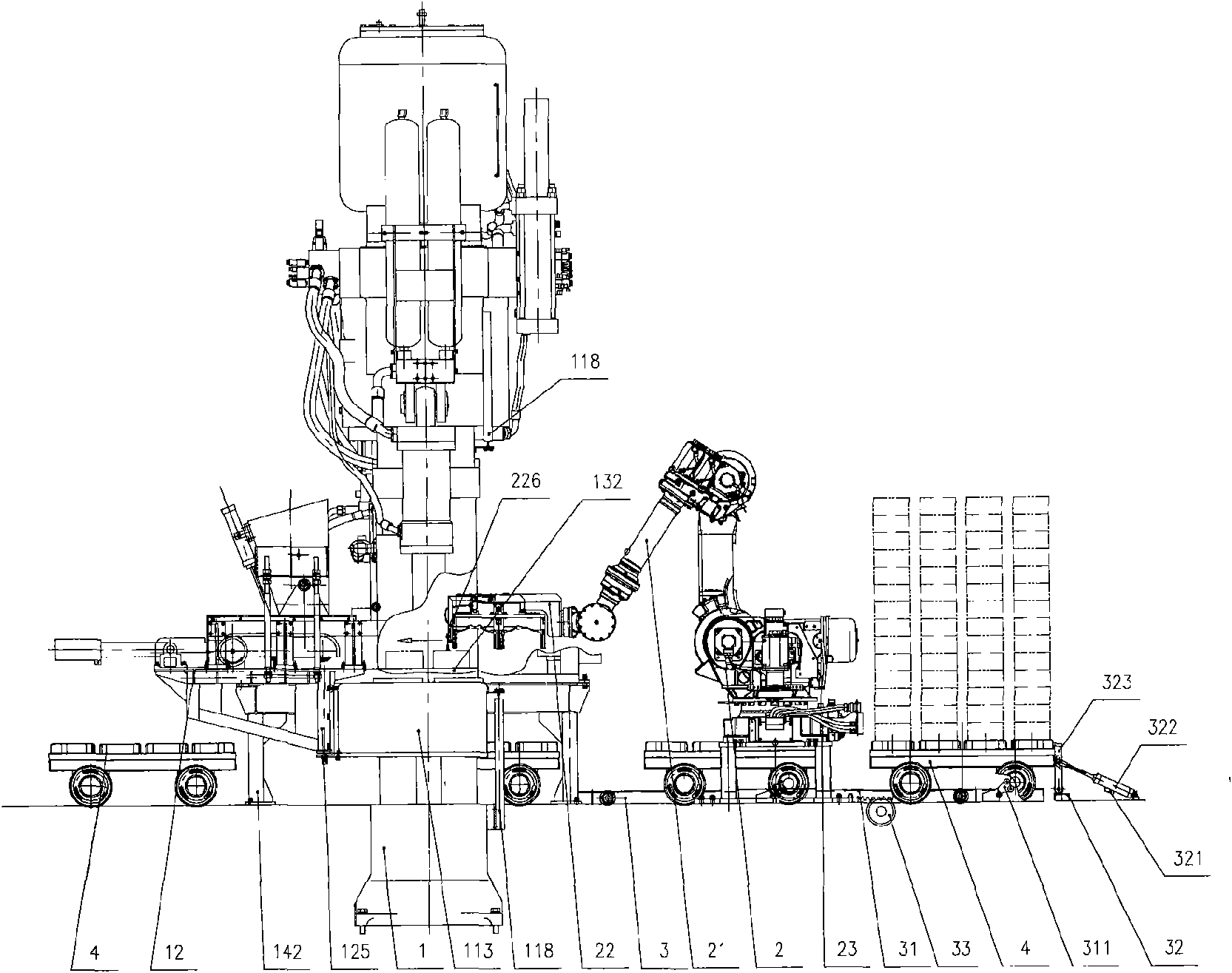

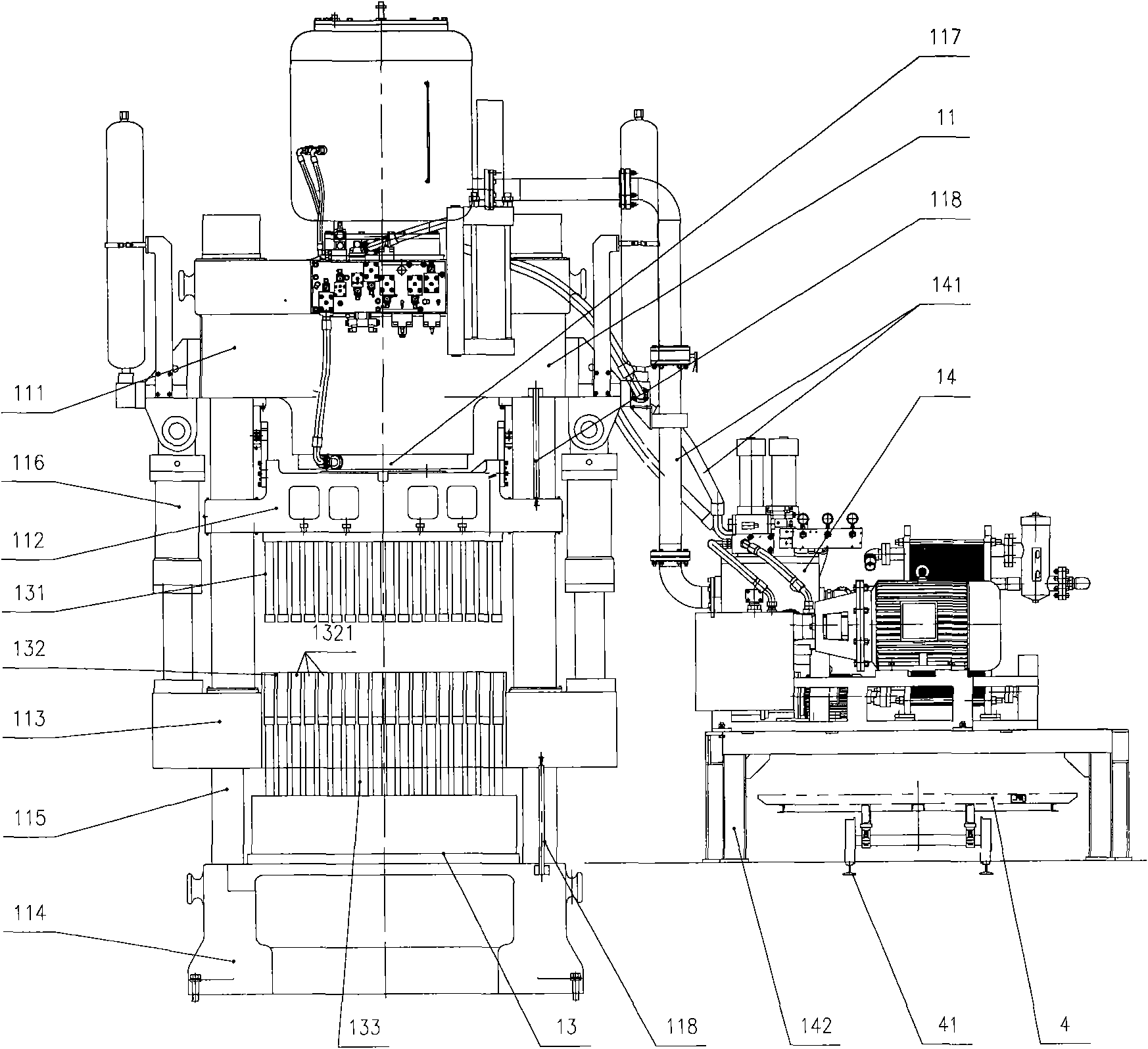

[0021] like figure 1 and figure 2As shown, the fully automatic hydraulic forming and intelligent stacking device for bricks according to the present invention includes a brick press (1), a stacking robot (2), an automatic feeder (3), a steam curing car (4) and an electric Control device (5). The palletizing robot (2) is installed between the brick press (1) and the automatic feeder (3), and the automatic feeder (3) is installed on the same side of the hydraulic station (14) in the brick press (1) , the hydraulic station (14) is installed on the pump station support (142), and the steam maintenance vehicle (4) enters the automatic feeder (3) from the pump station support (142), and the automatic feeder (3) is opposite to the steam maintenance vehicle (4 ) for positioning and feeding; the electric control device (5) is connected with the driving device and sensor of the brick press (1), palletizing robot (2) and automatic feeder (3) through the electric circuit (52), and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com