Pipe combined coaxial cable and manufacturing method thereof

A technology of coaxial cable and production method, which is applied in the direction of manufacturing coaxial cable, coaxial cable/analog cable, communication cable, etc., can solve the problems of not being able to take into account the future, high cable maintenance costs, and large secondary investment, etc., to achieve guaranteed Roundness, novel and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

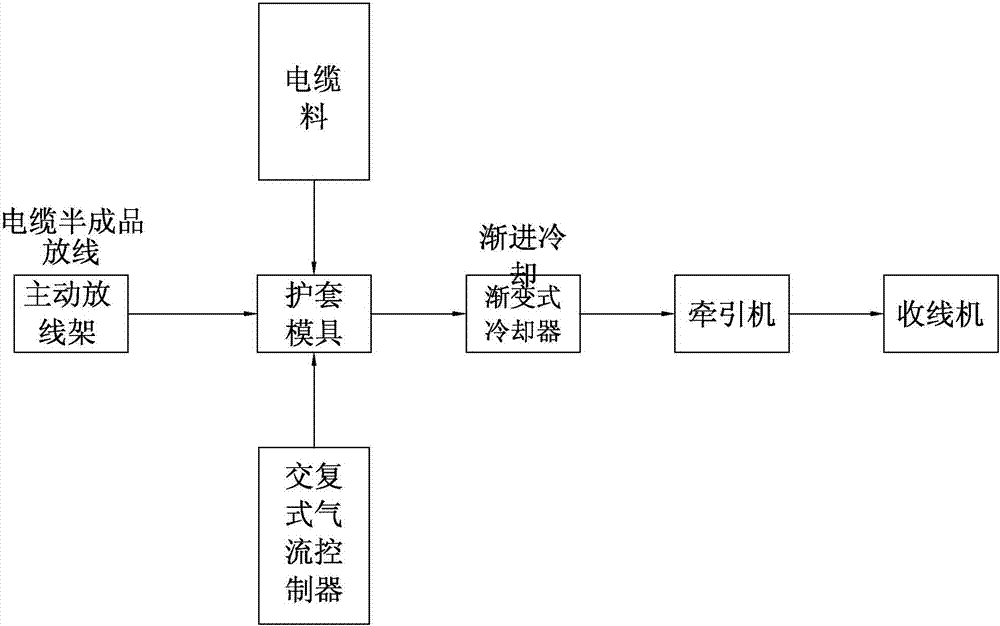

[0029] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

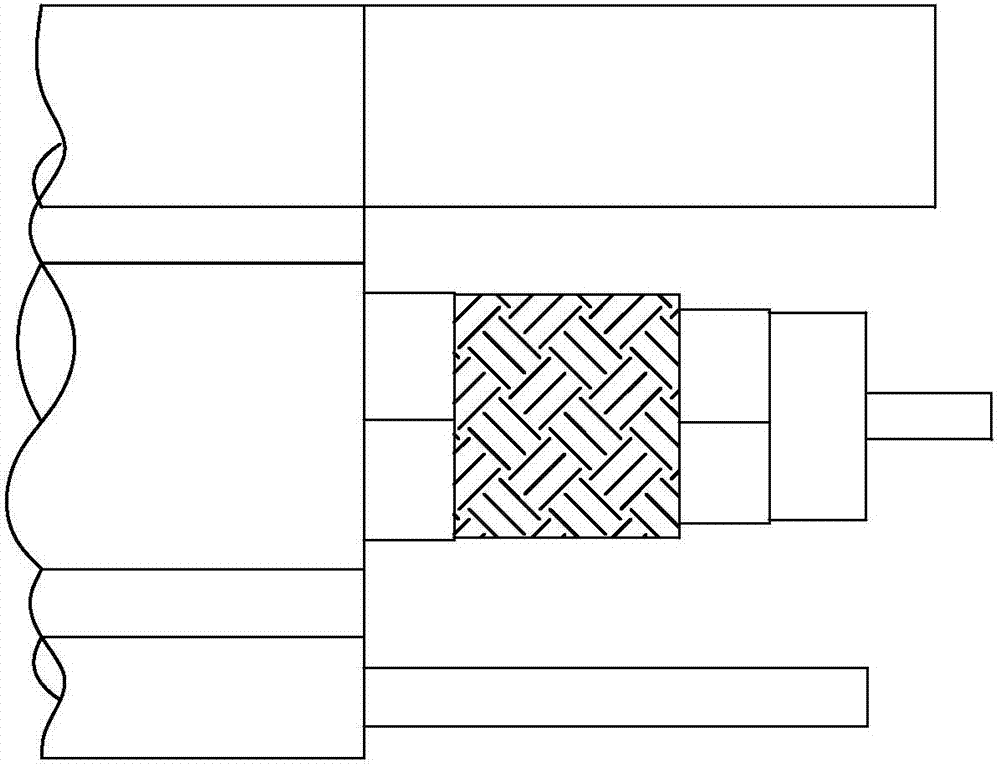

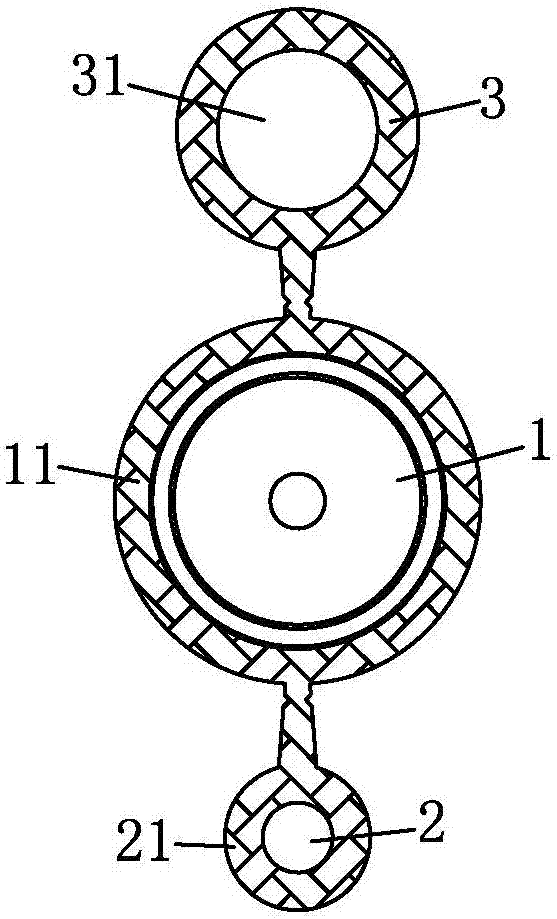

[0030] Such as figure 1 As shown, a pipe-combined coaxial cable includes a main cable 1 , an auxiliary cable 2 and an empty pipe 3 arranged in parallel.

[0031] The main cable is a transmission medium that provides signals to various communication systems; the main cable may be a coaxial cable, including an inner conductor and an insulating layer, a shielding layer and outer sheath.

[0032] The auxiliary cable module is used to provide auxiliary functions for the entire cable; the auxiliary cable may be a self-supporting wire that provides a load-bearing function for the entire cable, including phosphating steel wires and sheaths wrapped on the phosphating steel wires. The outer sheath 11 of the main cable is integrated with the sheath 21 of the auxiliary cable;

[0033] The empty pipe can facilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com