Integrated modular pressurized water reactor with 69 reactor core

A modular, pressurized water reactor technology, used in reactors, thermal reactors, nuclear reactors, etc., can solve the problems of unreasonable combination and arrangement of refueling process and modules, large reactor size and power ratio, and poor achievability. The effect of eliminating major water loss accidents, reducing construction costs and reducing construction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

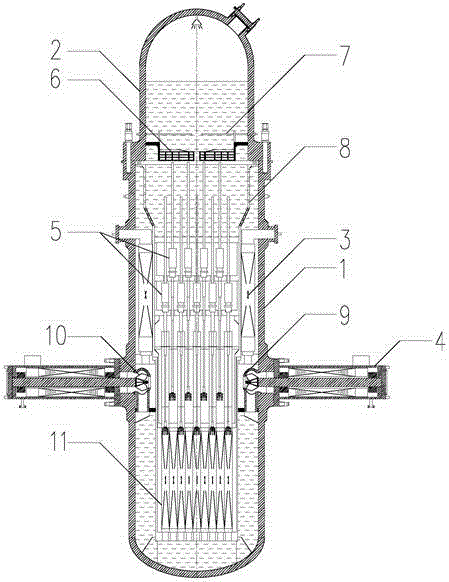

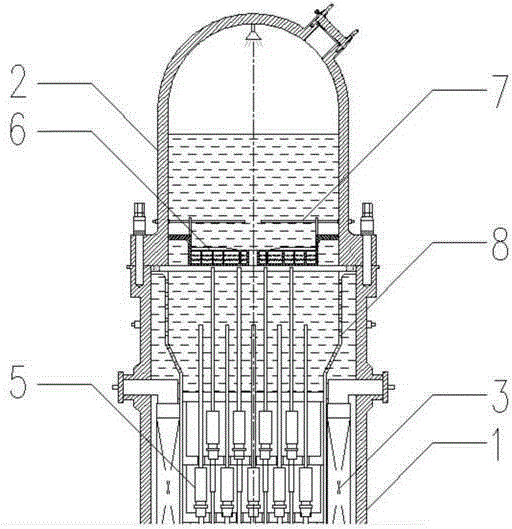

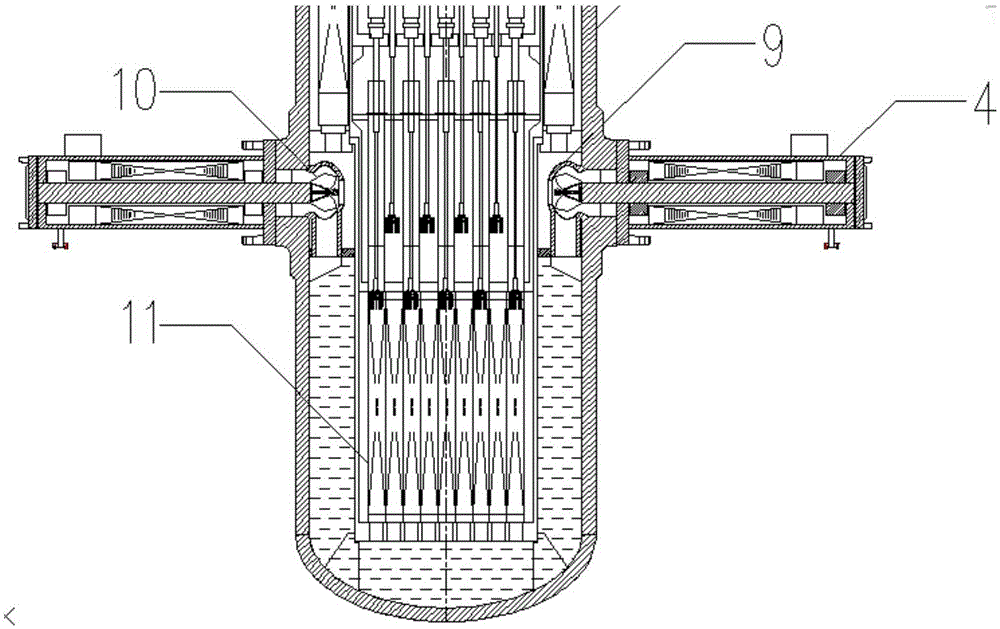

[0015] Such as figure 1 — image 3 As shown, the integrated modular pressurized water reactor with 69 cores of the present invention is as follows: a pressurizer 2, a plurality of modular steam generators 3, a plurality of wet winding main pumps 4, and a plurality of control rod drive mechanisms 5 are all Built into the reactor pressure vessel 1 and integrated into an integrated pressurized water reactor module; the pressurizer 2 doubles as the top cover of the reactor pressure vessel 1, and the inside of the pressurizer 2 is provided with a double-layer stainless steel inverted hat-shaped composite structure heat insulation plate 6 with an air interlayer , the electric heating element 7 is uniformly and horizontally arranged inside the voltage stabilizer 2 , and the electric heating element 7 is located above the heat insulation plate 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com